Wire-shell integrated water-cooling pouring type transformer and manufacturing method thereof

A manufacturing method, casting technology, applied in coil manufacturing, transformer/inductor coil/winding/connection, etc., can solve the problems of large occupied volume, large space, etc., achieve simple and convenient manufacturing process, solve complex structure, and simplify structure and the effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention are described in conjunction with the accompanying drawings.

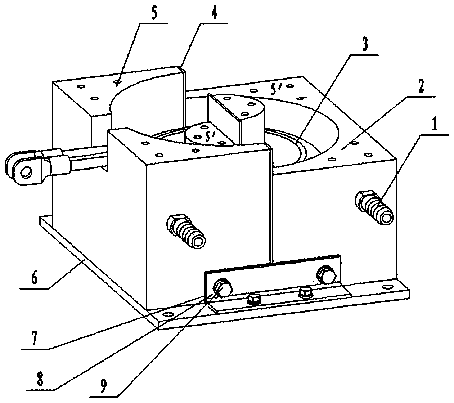

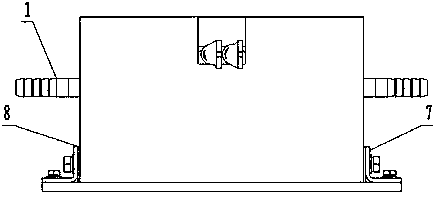

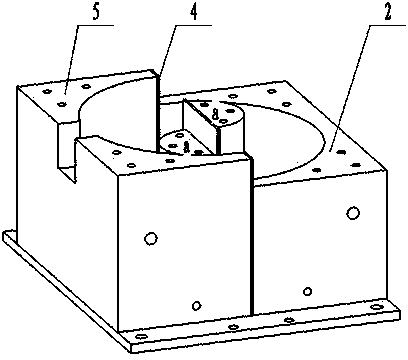

[0015] As shown in the figure: 1-Water connector 2-Secondary winding 1 3-Primary winding 4-Separator 5-Secondary winding 2 6-Insulation bottom plate 7-Clamp 8-Pull plate 9-Bolt

[0016] Implementation steps of the manufacturing method of the present invention:

[0017] Coil Manufacturing Method:

[0018] Formed on a ring core with primary wire wrapping image 3 Primary winding, crimped terminals at lead start and end. The secondary windings 2 and 5 are casted from aluminum and processed into a hollow core. At the same time, attention should be paid to such image 3 The top layer part a marked on the secondary winding 2 and secondary winding 5 shown in the above cannot be equal in height, the top layer part a of the secondary winding 2 is higher than the top layer part a of the secondary winding 5, which is convenient for later wiring, and finally in the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com