Autonomous obstacle-avoidance snakelike track walking-type crushing conveyor

A walking and conveyor technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of affecting the service life of the belt, easy deviation of the belt, poor flexibility, etc., to improve transportation efficiency and economic benefits. , the effect of reducing horizontal deviation and streamers, and reducing additional costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

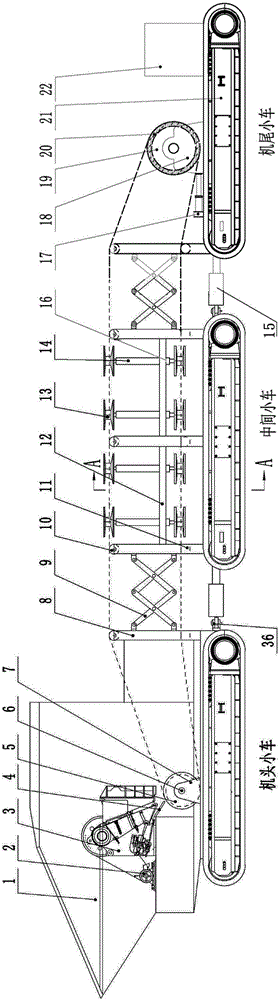

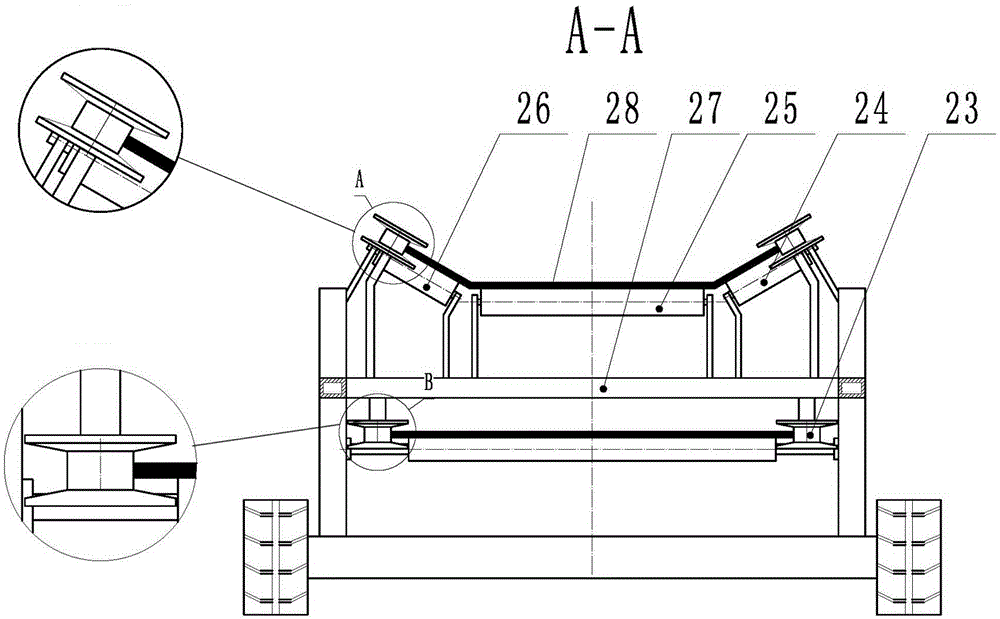

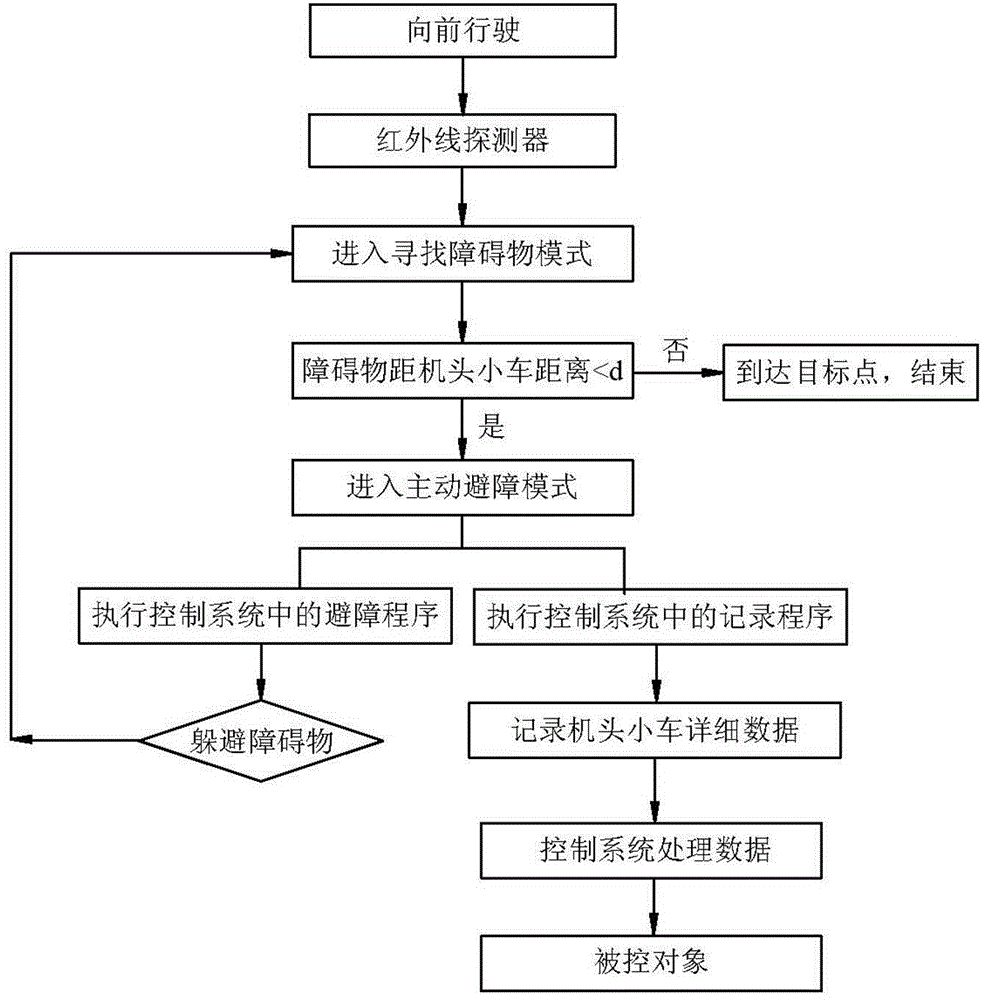

[0016] The following combination Figure 1~5 , detailing the specific structure of the present invention. The autonomous obstacle-avoiding snake-shaped crawler-type crushing conveyor is mainly composed of a head trolley crushing and screening device, a conveying device, a crawler walking device, an infrared detection direct-moving obstacle-avoiding device, a hydraulic control turning device, and a conveyor power and energy conversion device. .

[0017] Crushing and screening device for nose trolley.

[0018] figure 1 The nose crushing device 37 shown is composed of the nose material bucket 1, the jaw crusher motor 2, the jaw crusher 3, and the material baffle 4. When the material needs to be transported, the material is put into the nose material In the bucket 1, the jaw crusher 3 is driven by the jaw crushing motor 2 to crush large pieces of material, and the crushed small pieces of material are sent to the conveying device through the material baffle plate 4. The crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com