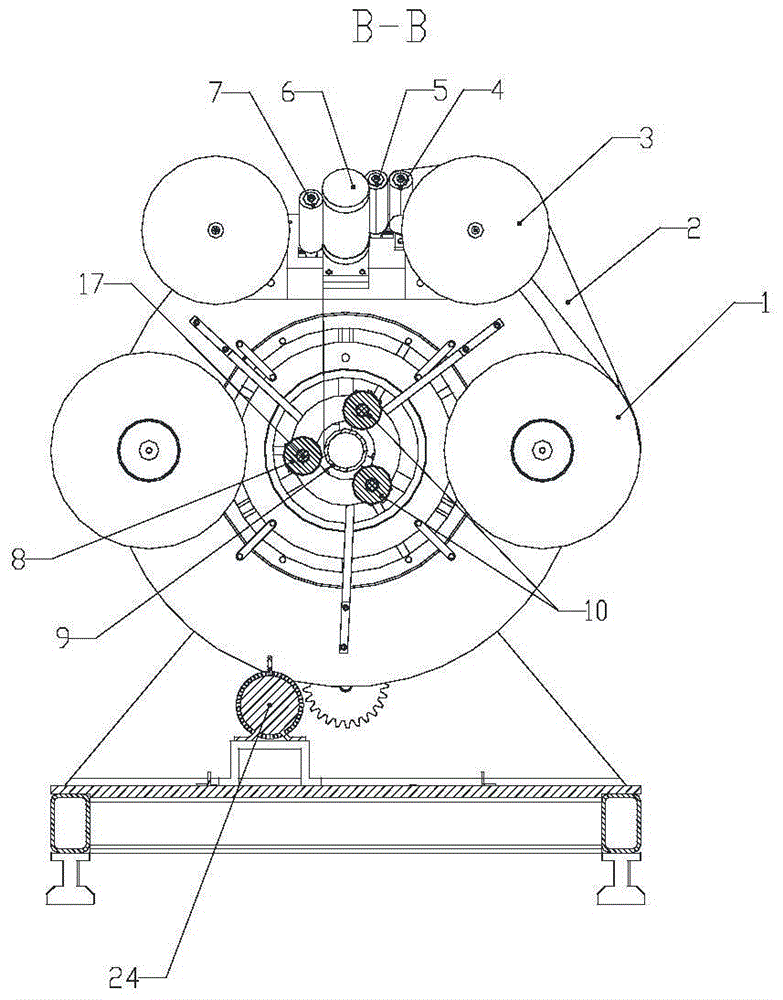

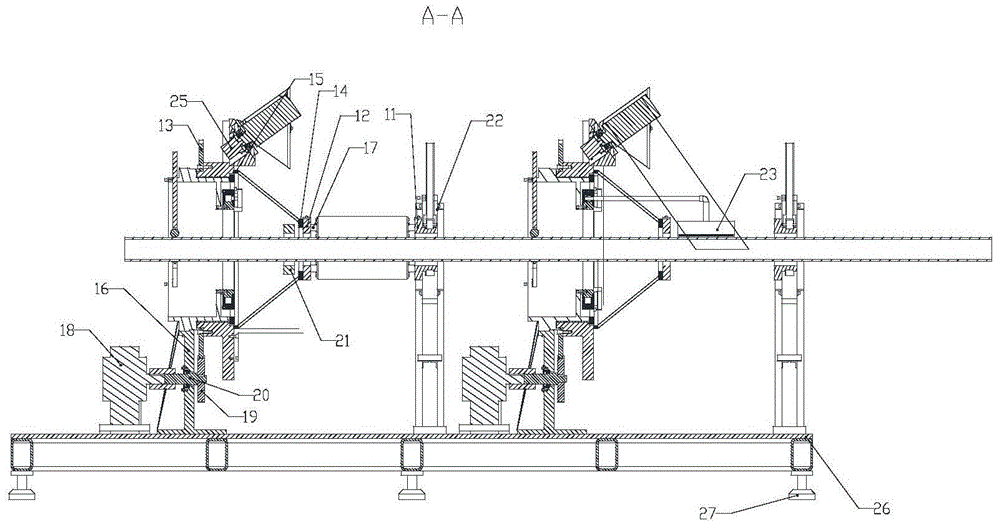

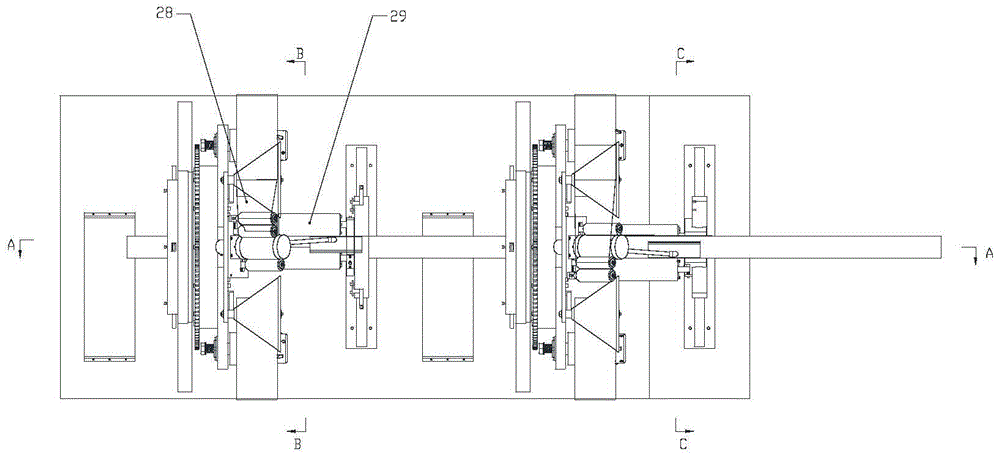

Composite tape winding machine for fully integrated reinforced thermoplastic pipe and its winding method

A technology for reinforced thermoplastic and composite tape, applied in the field of reinforced tape winding machine and its reinforced tape winding, which can solve the problem of equipment or process failure rate, maintenance and repair costs are difficult to maintain at a low level, and process parameter control consistency and stability It will not be too good and other problems, to achieve the effect of compact structure, guaranteed winding quality, and reduced production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] The base tube is made of ultra-high molecular weight polyethylene, the outer diameter is D=104mm, the inner diameter is 96mm, the selected composite belt has a bandwidth of L=200mm (the belt thickness is 0.6mm), and the composite belt is made of polyethylene.

[0098] The winding method is as follows:

[0099] In the first step, the winding angle α=54.63° is determined according to the outer diameter D of the base tube and the width L of the reinforcing belt; accordingly, the taper angle of the tapered belt roller is selected as 35.37°.

[0100] The second step is to start the front and rear two speed-regulating motors, and turn on the reinforcing tape winding machine. At the same time, according to the material of the substrate tube, choose to turn on the annular flame spray device or the first hot air blowing device, and follow the In the order that the big gear is in the front and the big gear on the side far from the extruder is in the order, first manually pull the free e...

Embodiment 2

[0112] The base tube is made of polypropylene, the outer diameter is D=308mm, the inner diameter is 298mm, and the standard reinforced belt with a bandwidth of L=300mm (the belt thickness is 0.8mm) is selected. The composite belt is made of polypropylene, and the number of simultaneous windings of each layer of composite belt is N = 2;

[0113] The first step is to determine the winding angle α=52.68° according to the outer diameter D of the base tube and the width L of the reinforcement belt; accordingly, the cone angle of the tapered belt roller is selected as 37.32°;

[0114] Among them, the base tube is heated by flame jet, and the outer flame temperature of the flame is 800-900°C until the surface of the base tube reaches a viscous flow state; the hot air outlet temperature of the second hot air blowing device is 400-500°C until the surface of the composite belt reaches a viscous flow state.

[0115] The rest are the same as in Example 1.

[0116] product inspection:

[0117] 1. V...

Embodiment 3

[0120] The material of the base tube is polyethylene, the outer diameter is D=622mm, the inner diameter is 612mm, and the standard reinforced belt with a bandwidth of L=300mm (the belt thickness is 0.8mm) is selected. The material of the composite belt is the same as that of the base tube. N=3;

[0121] The first step is to determine the winding angle α=62.95° according to the outer diameter D of the base tube and the width L of the reinforcing belt; the cone angle of the tapered belt roller is 37.05°;

[0122] Among them, the base tube is heated by flame jet, and the outer flame temperature of the flame is 800-900°C until the surface of the base tube reaches a viscous flow state; the hot air outlet temperature of the second hot air blowing device is 400-500°C until the surface of the composite belt reaches a viscous flow state.

[0123] The rest are the same as in Example 1.

[0124] product inspection:

[0125] 1. Visual inspection: the surface is smooth, no bubbling, no obvious over...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com