Preparation method and quality control method of coptis root detoxifcation soup particles

The technology of Huanglian Jiedu Decoction and formula granules is applied in the directions of pharmaceutical formulations, medical preparations containing active ingredients, antidote and the like, which can solve problems such as precipitation, and achieve the effects of simple preparation method, obvious effect and precise curative effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

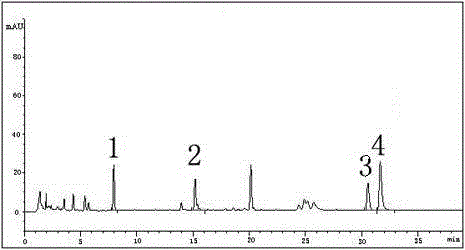

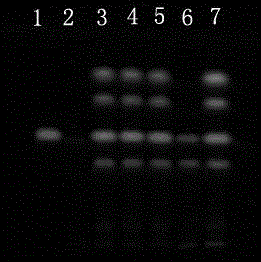

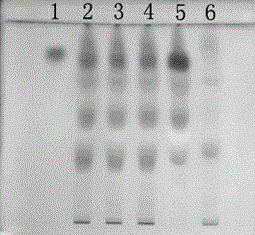

Image

Examples

Embodiment 1

[0044] a. Take 750g of Coptis chinensis, 500g of Scutellaria baicalensis, 500g of Cortex Phellodendron, and 750g of Gardenia, add water to decoct twice, add 25kg of water for the first time, decoct for 1 hour; add 30kg of water for the second time, decoct for 1.5 hours, and combine the filtrate , filter;

[0045] b. Concentrate the filtrate under reduced pressure in vacuo to an extract with a relative density of 1.04 at 95°C. At this time, a large amount of precipitation occurs in the extract, add 351g of β-cyclodextrin, keep the extract at 95°C, fully stir, and mix well to obtain clear ointment;

[0046] c. Take the above clear paste, add an appropriate amount of maltodextrin, spray dry, control the air inlet temperature at 175°C~185°C, and the outlet air temperature at 85°C~95°C to obtain dry extract powder, then add an appropriate amount of maltodextrin, and mix , carry out dry granulation, and finally obtain granules with a particle size in the range of 16-40 mesh and uni...

Embodiment 2

[0050] a. Take 450g of Coptidis Rhizome, 300g of Scutellaria Baicalensis, 300g of Phellodendron Phellodendron, and 450g of Gardenia, add water to decoct twice, add 15kg of water for the first time, decoct for 1.5 hours; add 12kg of water for the second time, decoct for 1 hour, and combine the filtrate , filter;

[0051] b. Concentrate the filtrate under reduced pressure in vacuum to an extract with a relative density of 1.05 at 95°C. At this time, a large amount of precipitation appears in the extract, add 210g of β-cyclodextrin, keep the extract at 100°C, stir and mix well Deqing ointment;

[0052] c. Take the above clear paste, add an appropriate amount of maltodextrin, spray dry, control the air inlet temperature at 175°C~185°C, and the outlet air temperature at 85°C~95°C to obtain dry extract powder, then add an appropriate amount of maltodextrin, and mix , carry out dry granulation, and finally obtain granules with a particle size in the range of 16-40 mesh and uniform c...

Embodiment 3

[0056] a. Take 900g of Coptis chinensis, 600g of Scutellaria baicalensis, 600g of Cortex Phellodendron, and 900g of Gardenia, add water to decoct twice, add 24kg of water for the first time, decoct for 2 hours; add 36kg of water for the second time, decoct for 1.5 hours, and combine the filtrate , filter;

[0057] b. The filtrate is concentrated under reduced pressure in vacuum to an extract with a relative density of 1.03 at 95°C. At this time, a large amount of precipitation occurs in the extract, and 421g of β-cyclodextrin is added. The extract is kept at 90°C, fully stirred, and mixed to obtain clear ointment;

[0058] c. Take the above clear paste, add an appropriate amount of maltodextrin, spray dry, control the air inlet temperature at 175°C~185°C, and the outlet air temperature at 85°C~95°C to obtain dry extract powder, then add an appropriate amount of maltodextrin, and mix , carry out dry granulation, and finally obtain granules with a particle size in the range of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com