Method for manufacturing electric device and shielding member

A technology of electronic equipment and shielding parts, which is applied in the electronic field, can solve the problems of increasing the thickness and thickness of electronic equipment, and achieve the effect of preventing electromagnetic waves from radiating outward and preventing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

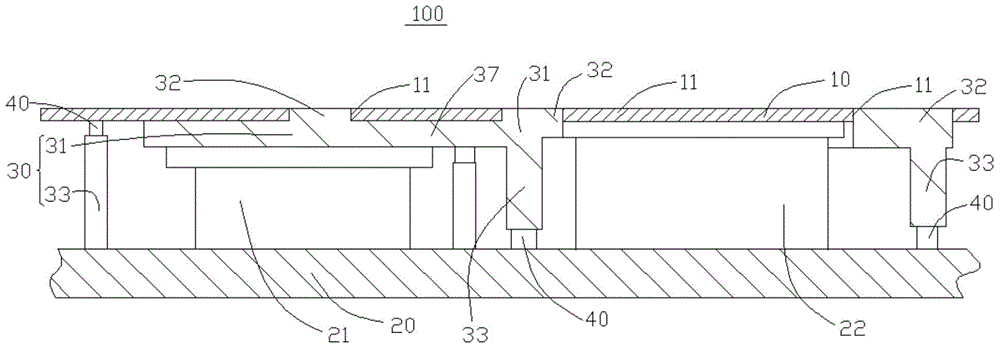

[0035] Such as figure 1 As shown, is a schematic structural diagram of an electronic device 100 according to an embodiment of the present invention. The electronic device can be mobile phone, PAD, computer, TV, server and other devices. The electronic device 100 includes a metal part 10 , a circuit board 20 and a shielding part 30 .

[0036] The metal piece 10 is provided with a through hole or a slot 11, and the shape and size of the hole or slot 11 can be set according to requirements. The function of opening the through hole or slot 11 is mainly to reduce the metal weight of the electronic device 100, or to release stress, or to make way for the electronic devices in the electronic device 100, or to be fixed on the metal part 10 for fixing. components. Therefore, as required, the number of said through holes or slots 11 can be one or more. Such as figure 1 As shown, the number of the through hole or slot 11 is one, and the purpose of opening the through hole or slot 11...

Embodiment 2

[0064] Based on the same inventive concept, the present application also provides a method for making a shield, such as Figure 7 As shown, it is a flow chart of the manufacturing method of the shielding member according to the embodiment of the present invention. Simultaneously combine figure 1 , the manufacturing method of the shielding member comprises the following steps:

[0065] Step 210, opening a through hole or a groove 11 on the metal part 10, the metal part 10 may be a metal stamping part or a metal forging part;

[0066] Step 220, forming a shielding part 31 on the metal part 10 by using a conductive plastic material through injection molding, and the shielding part 31 is used to shield the through hole or groove 11;

[0067] Step 230 , forming the enclosing portion 33 for enclosing the electronic device 21 on the circuit board 20 by metal or conductive plastic material.

[0068] Specifically, the method further includes: step 240, using plastic material to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com