Electrolyte additive for lithium secondary battery, non-aqueous electrolyte comprising electrolyte additive, and lithium secondary battery

一种非水电解液、锂二次电池的技术,应用在电解液添加剂,锂二次电池领域,能够解决增加气体、不均匀SEI膜、低温输出特性难以得到提高等问题,达到分解防止的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] [Preparation of Electrolyte Solution]

[0045] With ethylene carbonate (EC): propylene carbonate (PC): ethyl methyl carbonate (EMC): dimethyl carbonate (DMC) = 1.32: 1.20: 4.08: 4.28 (parts by weight) combined non- Aqueous organic solvent, and 0.5M LiPF 6 and 0.5M LiFSI were mixed, and with respect to 100 parts by weight of the non-aqueous electrolyte, 1% by weight of lithium difluorooxalate phosphate (LiDFOP), 0.2% by weight of (trimethylsilyl) propane Phosphate-based phosphoric acid ester (TMSPa), 1 wt% of 1,3-propene sultone (PRS), and 1 wt% of vinyl sulfate (ESa), thereby preparing an electrolyte solution.

[0046] [Manufacture of lithium secondary battery]

[0047] 92% by weight LiCoO as the positive electrode active material 2 , 4% by weight of carbon black as a conductive agent, 4% by weight of polyvinylidene fluoride (PVdF) as a binder were added to N-methyl-2-pyrrolidone (NMP) as a solvent, thereby preparing positive electrode mixture slurry. The positive ...

experiment example

[0055]

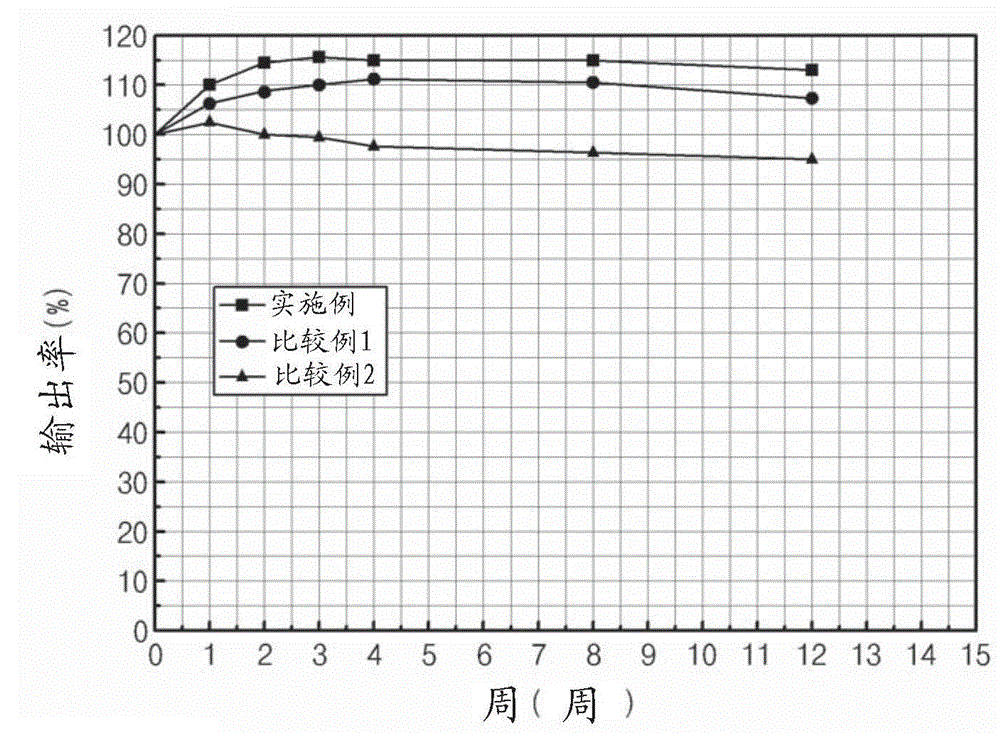

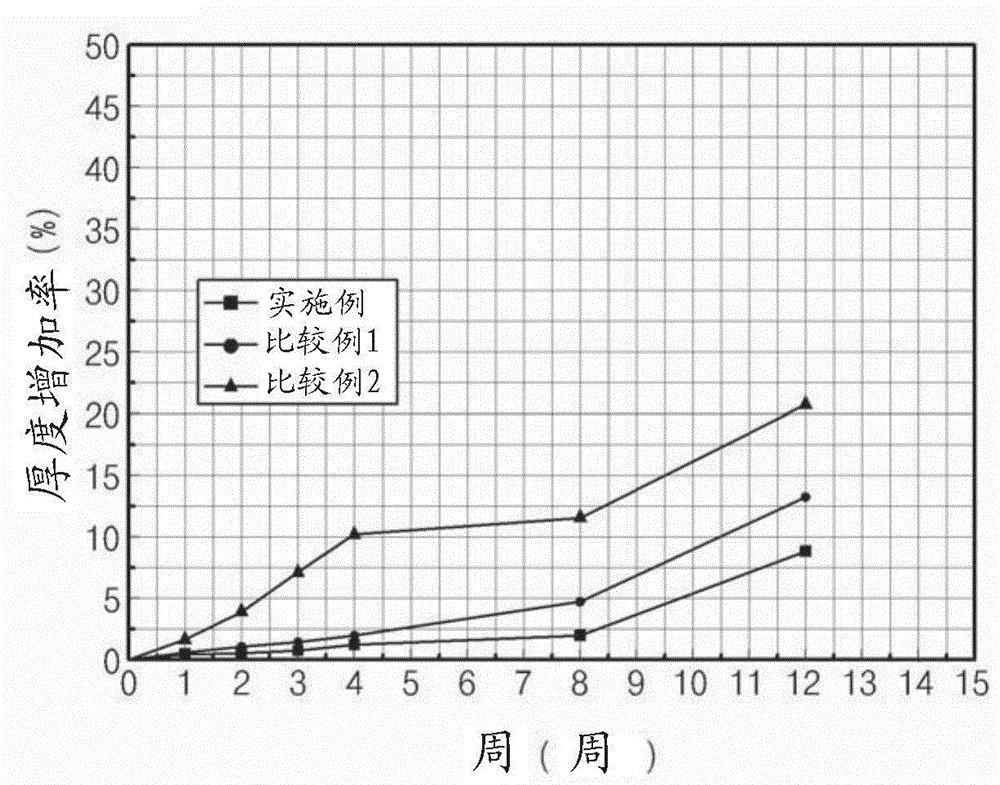

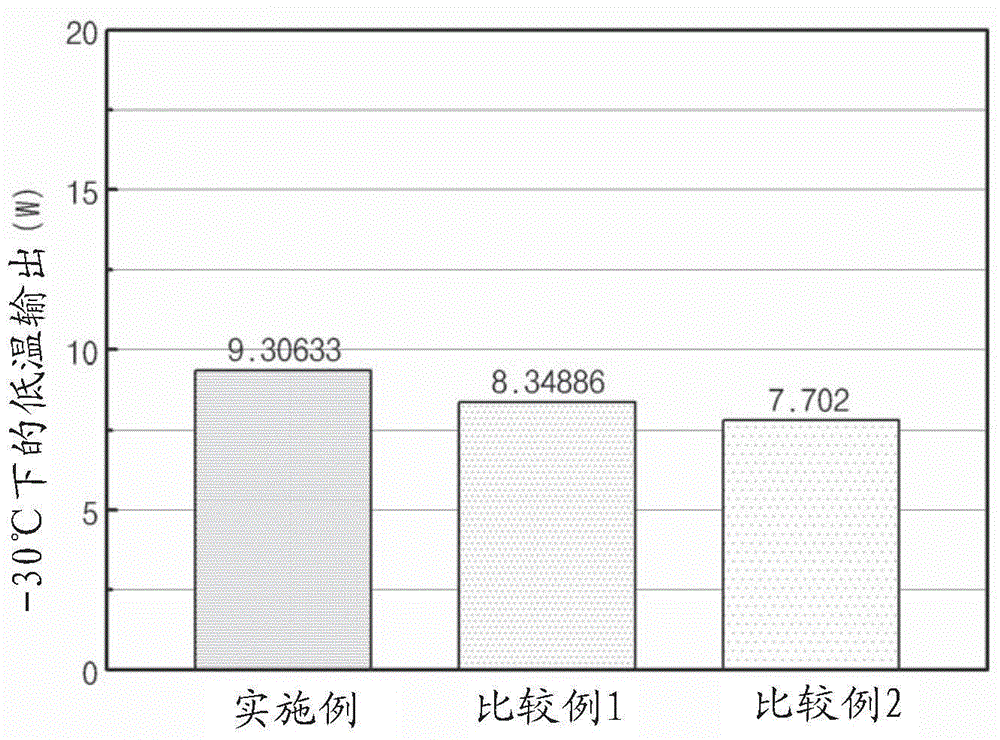

[0056] The secondary batteries manufactured in Example 1 and Comparative Examples 1 to 2 were stored at 60°C for up to 12 weeks, and the 1st week, 2nd week, 3rd week, 4th week, 8th week, 12th week The secondary battery was charged and discharged at 23° C. and 5 C for 10 seconds, respectively, and the output of the secondary battery was calculated using the voltage difference generated in this case. Based on the initial output (W, week 0), the output of the secondary battery corresponding to each week after high-temperature storage is calculated as a percentage (corresponding week output (W) / initial output (W)*100(% )), and put its result in figure 1 shown in . Experiments were performed at a state of charge (SOC) of 50%.

[0057] From figure 1 As can be seen from the above, the secondary battery of Example 1 is excellent in output characteristics even after high-temperature storage at 60°C. In particular, it was confirmed that in the case of the secondary batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com