A static and dynamic bond-slip whole process curve test device and test method

A bond-slip and test device technology, which is applied in the field of test research, can solve problems such as inability to adjust, difficulty, and difficulty in realizing the slip rate, and achieve the effect of simple device, convenient operation, and avoiding stiffness changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

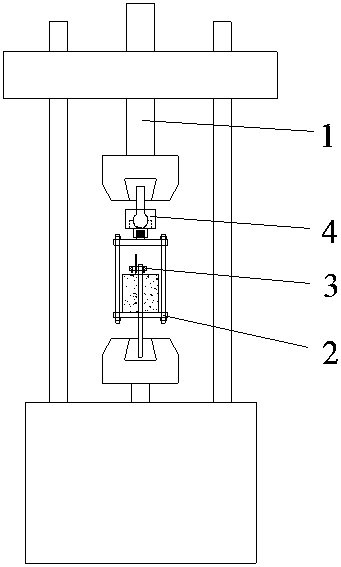

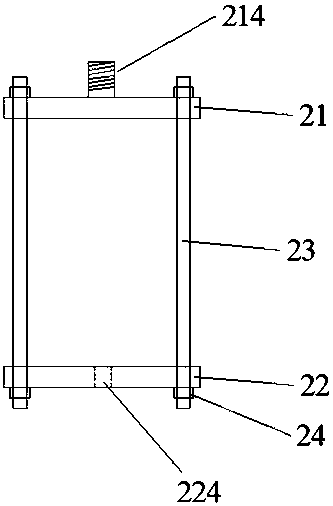

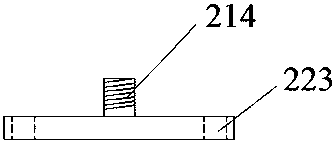

[0033] Such as figure 1 As shown, a static and dynamic adhesive slip whole process curve test device includes a hydraulic servo testing machine 1, a specimen drawing frame 2, an LVDT fixed protection card 3, and a ball dumpling 4; the hydraulic servo testing machine 1 includes at least one or LVDT11 with multiple test displacements can use the displacement of hydraulic servo testing machine 1 and the two signals of LVDT11 to carry out precise closed-loop control of the relative slip between the steel bar and concrete of the specimen; Figure 2 to Figure 8 As shown, the specimen drawing frame 2 is assembled from a top plate 21, a bottom plate 22, a screw 23, and a nut 24. The top plate 21 and the bottom plate 22 are provided with threaded holes 223 that can pass through the screw 23 at the four corners. The surface is connected with a top screw 214 adapted to the ball dumpling 4, and the center of the bottom plate 22 is provided with a round hole 224 passing through the steel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com