Preparation method of transmission electron microscopy film sample for in-situ application of electric field and stress

A technology for transmission electron microscopy and sample preparation, which is applied in the field of in-situ transmission electron microscopy of epitaxial thin film materials, and can solve the problem of not being able to provide the space required for positioning and moving nanometer probes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

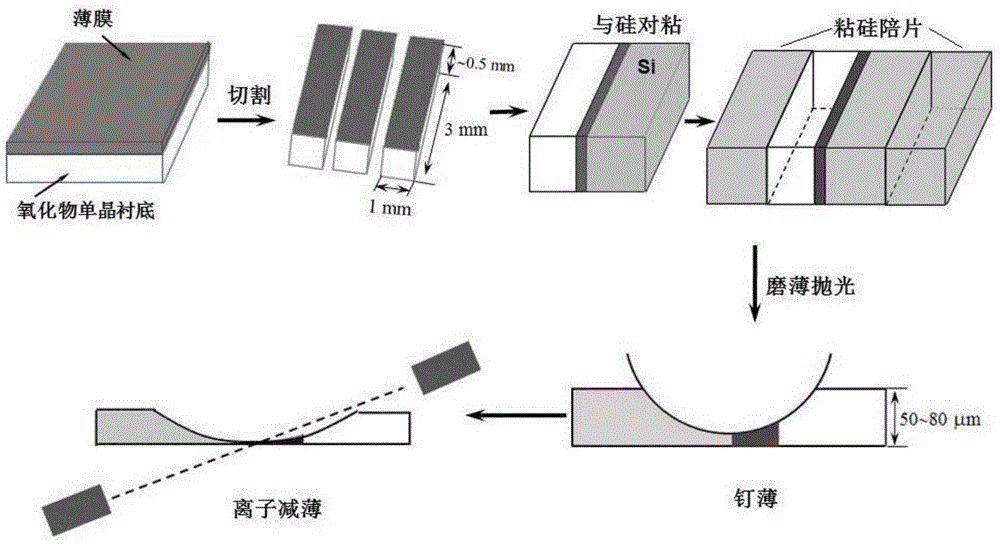

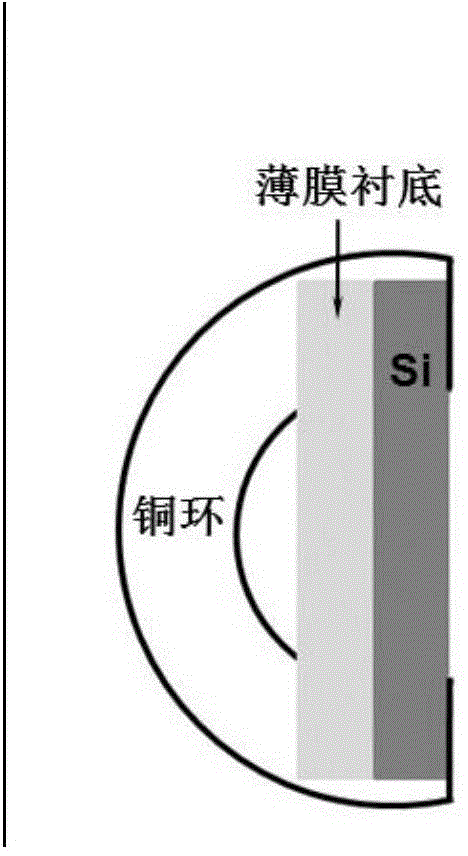

[0025] Such as figure 1 As shown, this embodiment provides a method for preparing thin film cross-section samples for in-situ application of electric field and stress in transmission electron microscopy. Using the characteristic that the ion thinning rate of Si material is much higher than that of single crystal oxide, Si sheets and thin film materials are selected For bonding, the Si sheet is knocked off by argon ions before the film and the substrate, so that the epitaxial film is exposed, which is beneficial to apply the electric field and stress through the probe. It specifically includes the following steps:

[0026] (1) Film cutting and Si one-side bonding

[0027] Will grow the BiFeO 3 thin film GdScO 3 Oxide single crystals and single crystal Si are cut into strips with a size of 3mm×1mm×0.5mm. Si bar polished surface and BiFeO 3 The membr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com