Coal shearer motor cooling control system and method

A cooling control and shearer technology, which is applied to electromechanical devices, cooling/ventilation devices, electrical components, etc., can solve problems such as affecting water supply, affecting coal mining operations, and breaking water pipes, achieving convenient operation, wide practicability, and improved performance. The effect of the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

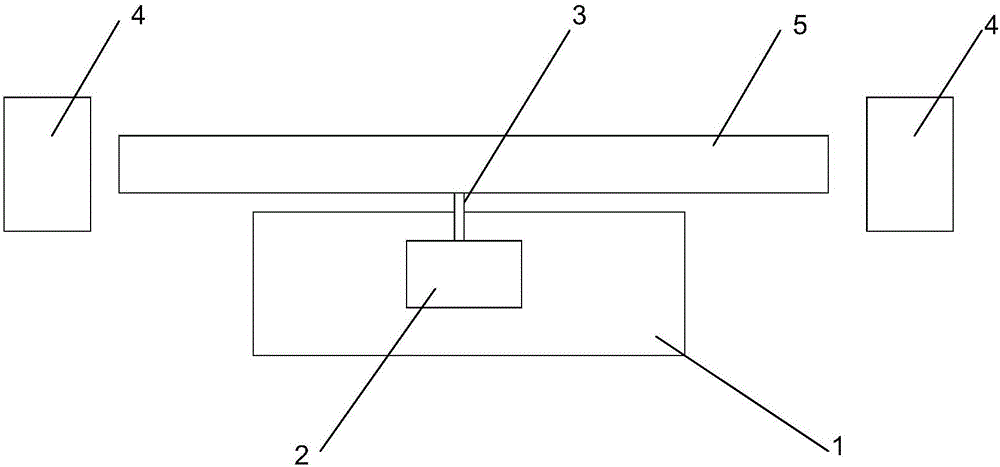

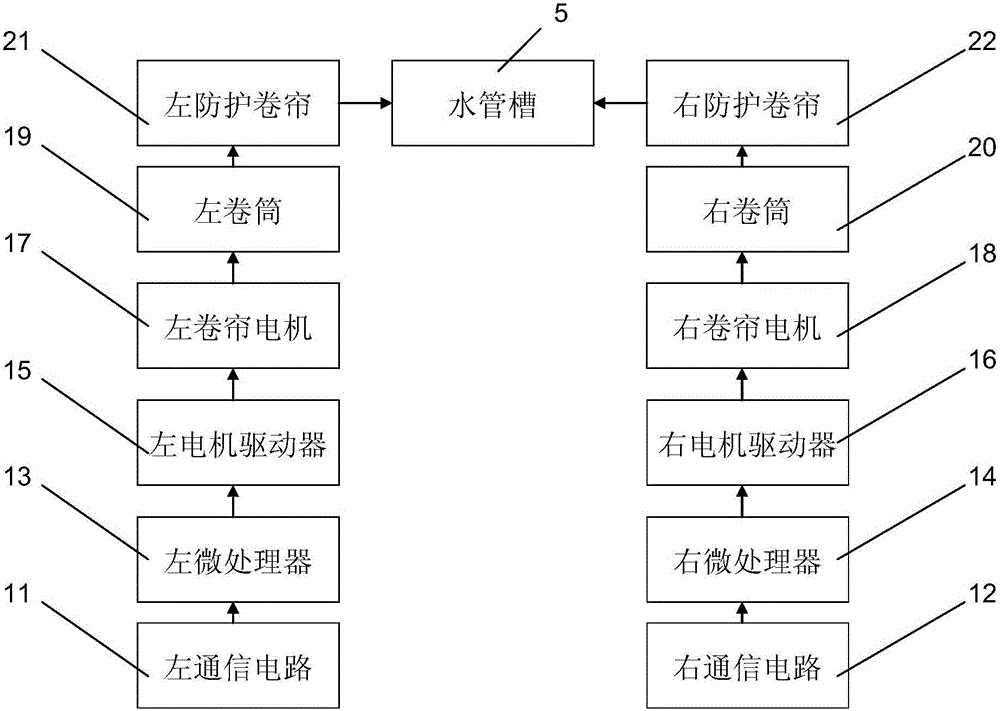

[0025] The cooling control system of the shearer motor of the present invention is mainly composed of three parts: an airborne water pipe retractable control device 2 , a ground water pipe protection control device 4 and a water pipe groove 5 . The on-board water pipe retractable control device 2 is installed on the coal shearer 1, the water pipe 3 drawn from the water pipe tank 5 is connected to the water-carrying pipe retractable control device 2, and the ground water pipe protection control device 4 has two sets, which are respectively installed in the coal mining machine Both sides of the machine walking track are coordinated and controlled with the airborne water pipe retractable control device 2 through communication, such as figure 1 shown.

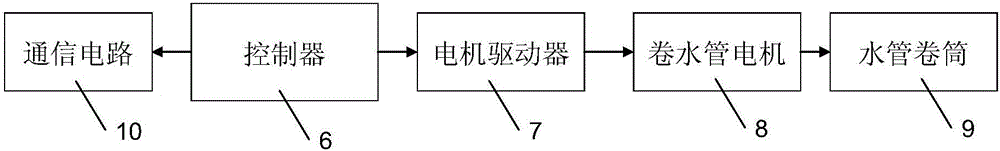

[0026] The airborne water pipe retractable control device 2 is composed of a controller 6 , a motor driver 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com