Gyrating centre current-collector central water device for gantry crane

A technology of gantry crane and slewing device, which is applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems such as the inability of gantry cranes to achieve electrical safety, and achieve convenient daily maintenance, reliable circuit isolation, and ensure safety and quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

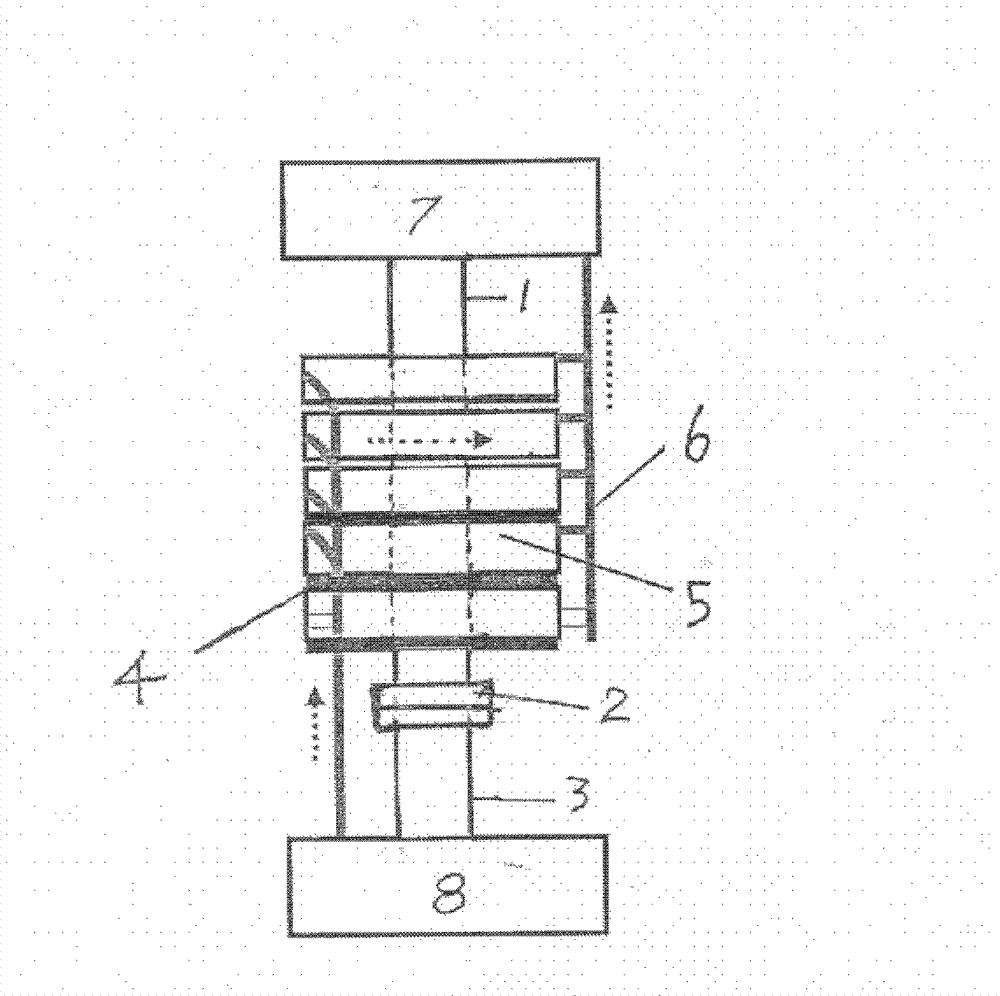

[0014] Such as figure 1 In the central water passing device of a slewing center collector of a gantry crane shown, there is a vertical water supply pipe 1 in the center between the upper equipment 7 and the lower equipment 8 of the gantry crane, and a sealed rotary device 2 in the middle of the water supply pipe. There is a sealing waterproof layer 3 outside the water supply pipe and the sealing rotary device, and the water supply pipe on the upper part of the sealing rotary device has a central receiver bracket 4, the central receiver 5 is installed on the central receiver bracket, and the multi-channel power supply circuit 6 is installed on the central receiver on electrical appliances.

[0015] This technology is applied to the central collector in the rotating column of the gantry crane. A waterway is set at the axis of the central receiver, the upper part of the waterway is connected with the upper equipment of the door operator, the lower part of the waterway is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com