Urea-containing printing and dyeing wastewater processing equipment and processing method thereof

A technology for printing and dyeing wastewater and treatment equipment, which is used in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. to improve biodegradability, realize denitrification and denitrification, and improve effluent quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

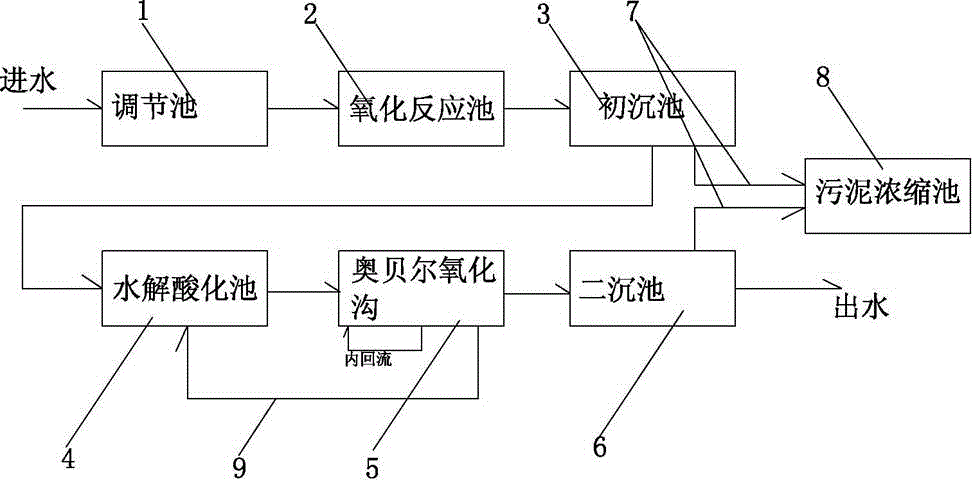

[0026] Please refer to the attached figure 1 As shown, the present invention is a kind of urea-containing printing and dyeing wastewater treatment equipment, which is composed of a regulating tank 1, an oxidation reaction tank 2, a primary sedimentation tank 3, a hydrolytic acidification tank 4, an oxidation ditch 5, and a secondary sedimentation tank 6.

[0027] Wherein, the regulating tank 1, the oxidation reaction tank 2, the primary sedimentation tank 3, the hydrolytic acidification tank 4, the oxidation ditch 5 and the secondary sedimentation tank 6 are connected in sequence to form an integrated processing equipment.

[0028] Further, a sludge discharge pipe 7 is provided at the bottom of the primary sedimentation tank 3 and the secondary sedimentation tank 6 , and the sludge discharge pipe 7 is connected to a sludge concentration tank 8 .

[0029] The oxidation ditch 5 is an Aubert oxidation ditch, and a mixed liquid return pipe 9 is arranged in the central area thereof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com