Tyre managing system

A management system and tire technology, applied in tire measurement, tire parts, vehicle accessories for anti-theft, etc., can solve problems such as inability to grasp tires, enterprise expenditure, tire use and wear, etc., to reduce work consumption, reduce misoperation, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

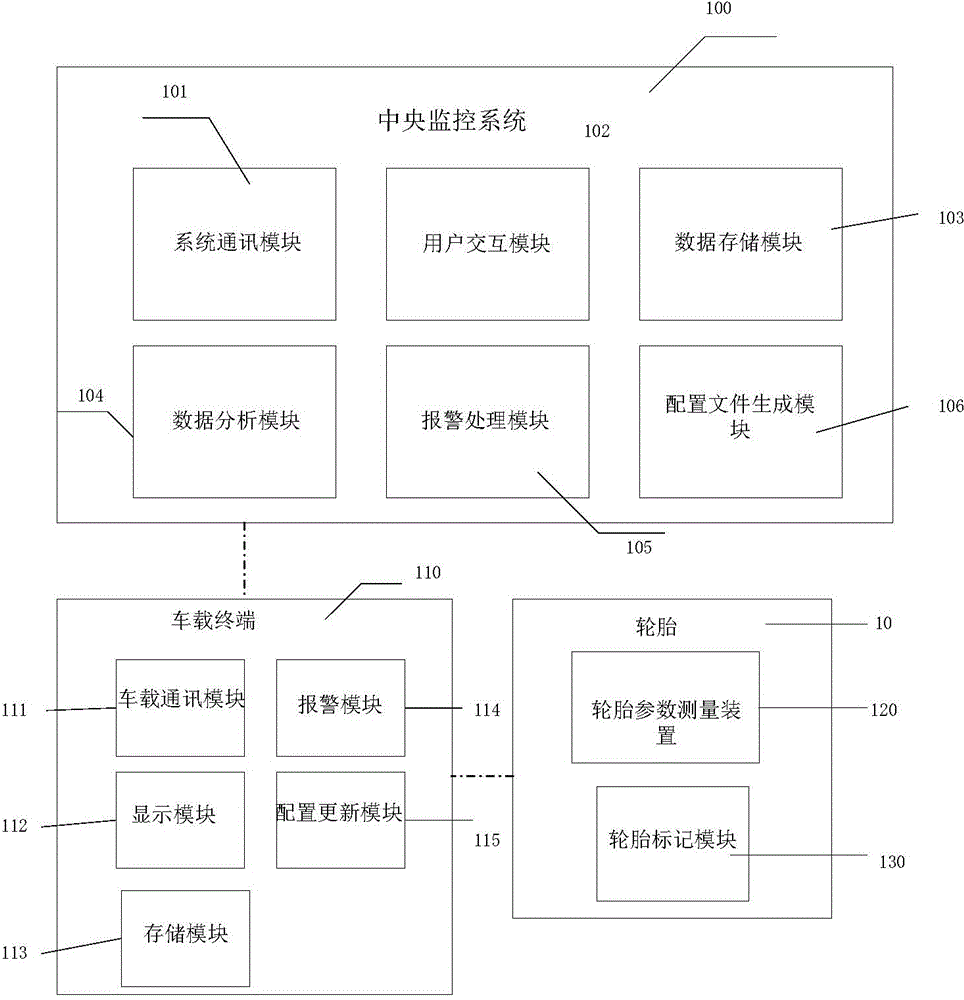

[0027] figure 1 A schematic structural diagram of an embodiment of the present invention is shown. As shown in the figure, in this embodiment, the tire management system includes a central monitoring system 100 , a vehicle-mounted terminal 110 , a tire parameter measuring device 120 and a tire marking module 130 .

[0028] The tire parameter measuring device 120 measures tire running (status) data, and the vehicle-mounted terminal 110 generates alarm information based on the running data, and the two kinds of data are sent to the central monitoring system 100 respectively, and the central monitoring system 100 stores them in respective corresponding Tire operation data and alarm database. And displayed on the display device of the central monitoring system 100. The operator can perform viewing operations or management operations through the user interaction module, and enter the management information of the fleet into the database of the central monitoring system 100 .

[...

Embodiment 2

[0051] figure 2 A structural block diagram of another embodiment of the present invention is shown. In this embodiment, besides the central monitoring system 100 , the vehicle terminal 110 , the tire parameter measuring device 120 , and the tire marking module 130 , the tire management system of the present invention adds a handheld operation terminal 140 . The handheld operator includes an information reading module 141, an input module 142, an output module 143, and a communication module 144. The information reading module is used to read tire marking information from the tire marking module of the tire. In this embodiment, the tire marking module adopts an active RFID module, therefore, the information reading module mainly receives tire operation data from the active RFID.

[0052] The input module 142 and the output module 143 may be integrally formed, or may be independent components. It is mainly used to display operation instructions and other information to the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com