A servo tool holder structure and its application method

A servo tool holder and component technology, applied in the direction of manufacturing tools, tool holders, precision positioning equipment, etc., can solve the problems of cumbersome structure, complex motion, and increase the difficulty of tool holder parts assembly, so as to simplify the design and installation The difficulty of debugging and the effect of improving the transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

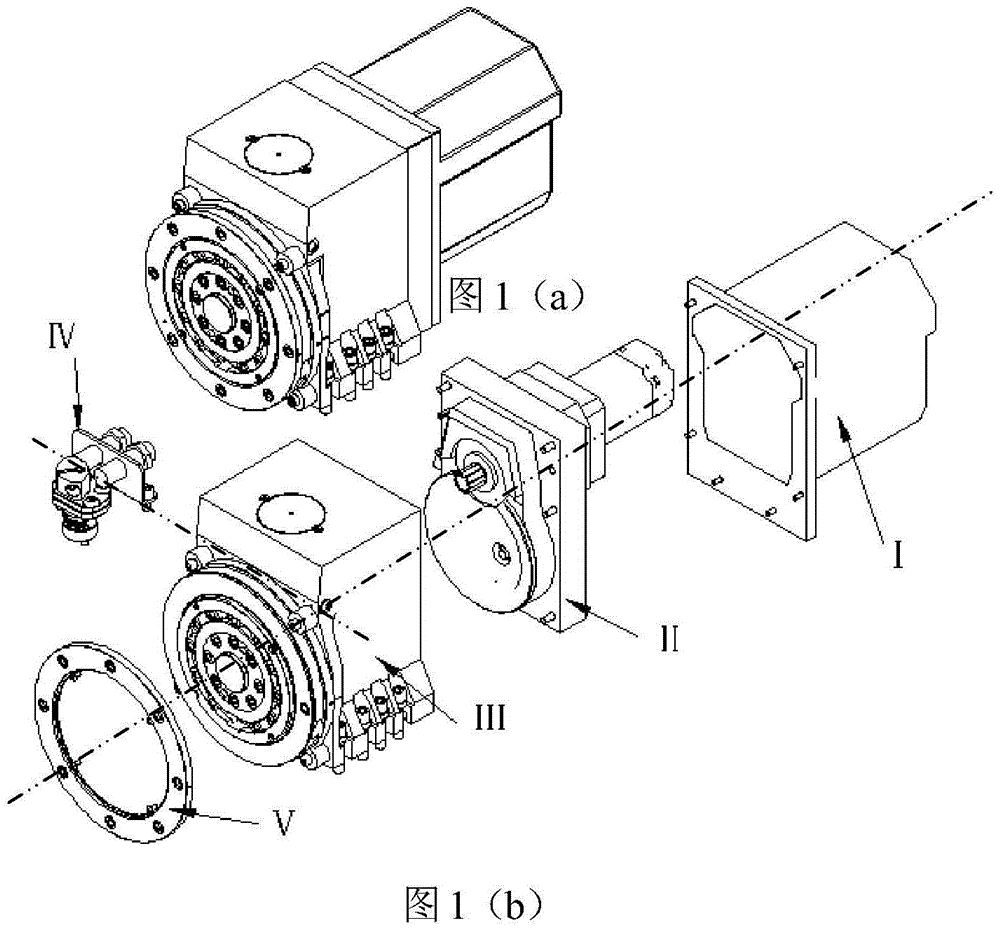

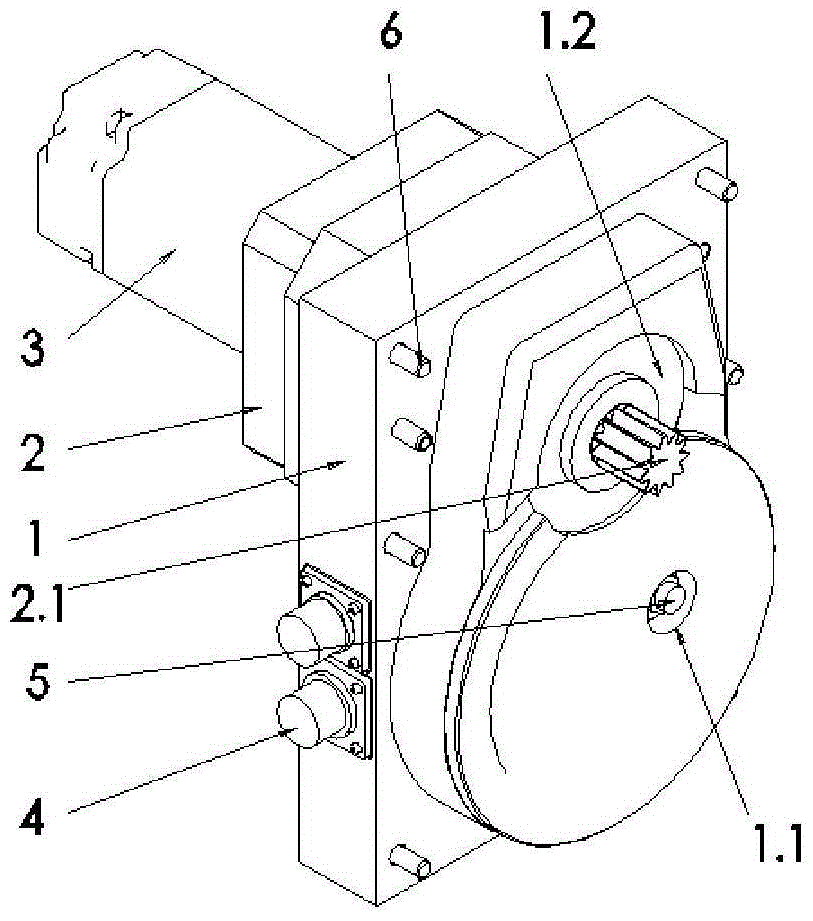

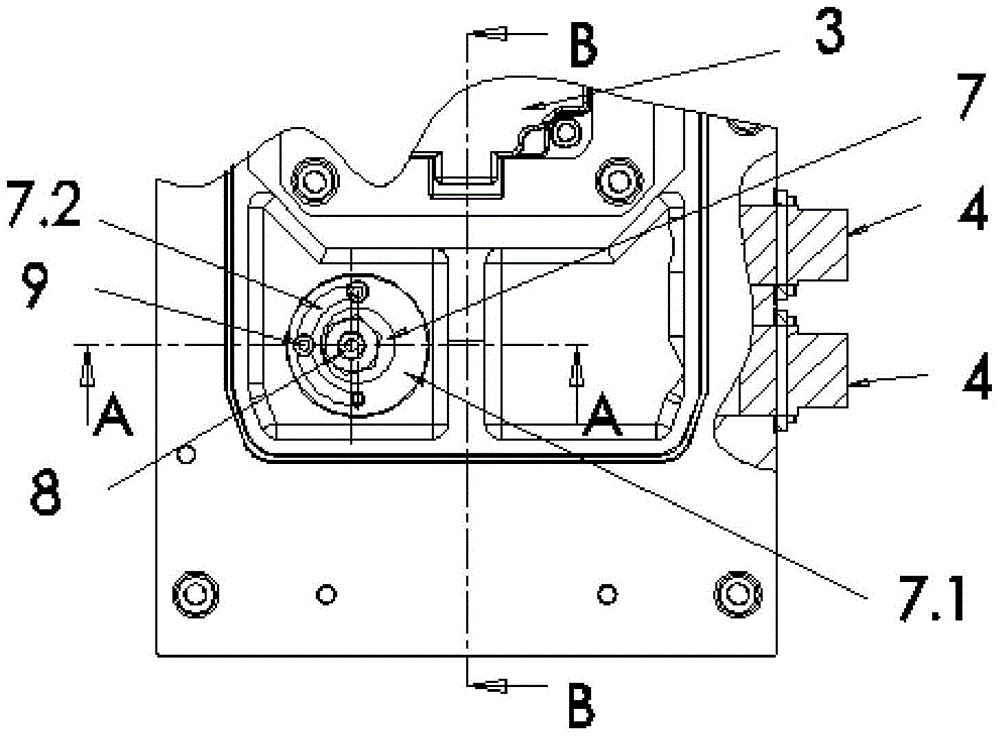

[0033] As shown in Figure 1(a)-(b), Figure 10-1 and Figure 10-2 As shown, the servo tool holder structure of the present invention is applied to CNC lathes and CNC turning centers to realize the tool change function, and mainly includes casing I, rear cover assembly II, box assembly III, proximity switch assembly IV, water diversion plate V, casing I is set on the tail of the rear cover assembly II, the reducer end of the rear cover assembly II is connected to the rear end of the box assembly III, the proximity switch assembly IV is installed in the box body of the box assembly III, and the water diversion plate V is installed in the on the moving toothed plate of case assembly III. The motor and reducer of the rear cover assembly Ⅱ are installed on the rear cover to provide power source; the box assembly Ⅲ adopts the structure of three ratchet plates for positioning, and the proximity switch assembly Ⅳ adopts the cam structure to detect the locking state of the knife post....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com