High-dispersion supported palladium/tungsten carbide catalyst and preparation method thereof

A technology of tungsten carbide catalyst and supported palladium, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the necessity and urgency of cost-increasing non-Pt catalyst research and development, and the difficulty of uniform dispersion of precious metals , low utilization rate of catalyst, etc., to achieve the effect of rich Pd resources, simple and easy preparation process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: 20% Pd / WC 10 (20% means that the mass content of the active component Pd is 20%, and 10 means 10nm SiO 2 template)

[0034] Weigh 2g of ammonium metatungstate, dissolve 2.62g of glucose in deionized water at 80°C, adjust the pH to 11 with NaOH, add 10nm SiO 2 Sol 5.3g (mass fraction 30%), stirred at 80°C for 3h; dried at 120°C for 5h to obtain a precursor solid. The above precursor solids were placed in a tube furnace, N 2 At 5°C min under atmosphere -1 The temperature was programmed to 550°C at a rate of 2°C min -1 The rate was programmed to raise the temperature to 900°C, react at a constant temperature for 3 hours, and cool naturally to obtain a precursor composite material. Put the above precursor composite material in 2M NaOH solution, stir at 40°C for 12h, filter, wash, vacuum dry at 80°C for 6h, and weigh to obtain highly dispersed tungsten carbide material WC 10 . Dissolve 0.5588g of sodium citrate in 50mL of deionized water, add chloropalladiu...

Embodiment 2

[0035] Example 2: 20% Pd / WC 20 (20% means that the mass content of the active component Pd is 20%, and 20 means 20nm SiO 2 template)

[0036] Weigh 2g of ammonium metatungstate, dissolve 2.62g of glucose in deionized water at 80°C, adjust the pH to 11 with NaOH, add 20nm SiO 2 Sol 4g (mass fraction 40%), stirred at 80°C for 3h; dried at 120°C for 5h to obtain the precursor solid. The above precursor solids were placed in a tube furnace, N 2 At 5°C min under atmosphere -1 The temperature was programmed to 550°C at a rate of 2°C min-1 The rate was programmed to raise the temperature to 900°C, react at a constant temperature for 3 hours, and cool naturally to obtain a precursor composite material. Put the above precursor composite material in 2M NaOH solution, stir at 40°C for 12h, filter, wash, vacuum dry at 80°C for 6h, and weigh to obtain highly dispersed tungsten carbide material WC 20 . Dissolve 0.5588g of sodium citrate in 50mL of deionized water, add chloropalladium ...

Embodiment 3

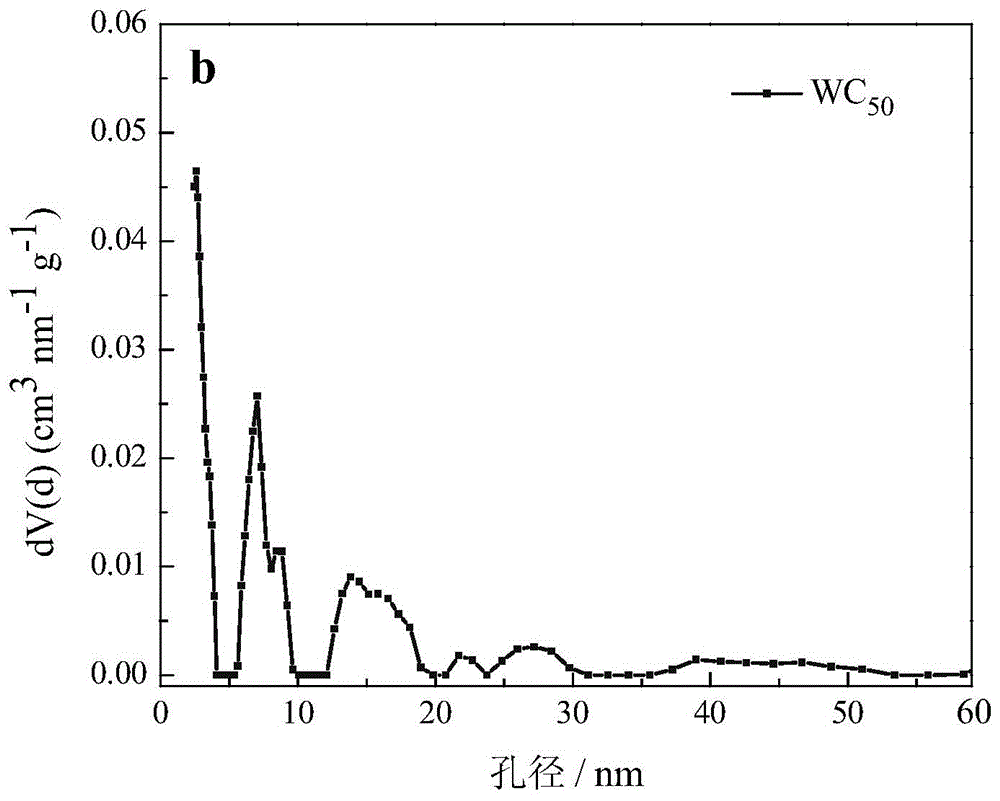

[0037] Example 3: 20% Pd / WC 50 (20% means that the mass content of the active component Pd is 20%, and 50 means 50nm SiO 2 template)

[0038] Weigh 2g of ammonium metatungstate, dissolve 2.62g of glucose in deionized water at 80°C, adjust the pH to 11 with NaOH, add 50nm SiO 2 Sol 4g (mass fraction 40%), stirred at 80°C for 3h; dried at 120°C for 5h to obtain a precursor solid. The above precursor solids were placed in a tube furnace, N 2 At 5°C min under atmosphere -1 The temperature was programmed to 550°C at a rate of 2°C min -1 The rate was programmed to raise the temperature to 900°C, react at a constant temperature for 3 hours, and cool naturally to obtain a precursor composite material. Put the above precursor composite material in 2M NaOH solution, stir at 40°C for 12h, filter, wash, vacuum dry at 80°C for 6h, and weigh to obtain highly dispersed tungsten carbide material WC 50 . Dissolve 0.5588g of sodium citrate in 50mL of deionized water, add chloropalladium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com