Ball screw drive, in particular for a locking brake of a motor vehicle

A technology of transmission device and ball screw, which is applied in the direction of transmission device, brake actuator, mechanical equipment, etc., and can solve the problem that the starting position of the ball or the ball cage cannot be reached.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

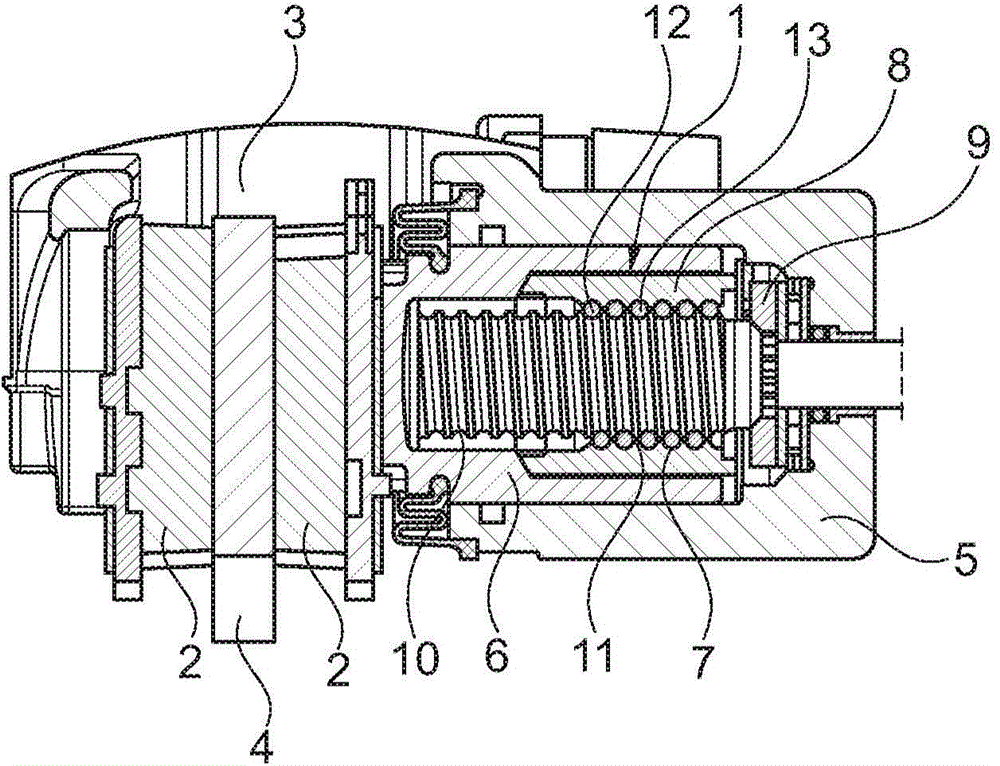

[0025] figure 1 Shown is a service brake of a motor vehicle in combination with a parking brake according to the invention, wherein the parking brake is associated with a ball screw drive 1 according to the invention. A brake disk 4 is arranged in a known manner between the two brake pads 2 of the brake caliper 3 . A brake piston 6 is arranged in the housing 5 . The brake piston 6 can be acted upon with hydraulic fluid and can be pressed along its piston axis in the direction of the brake pad 2 . When the brake piston 6 is actuated, the brake disk 4 is clamped between two brake pads.

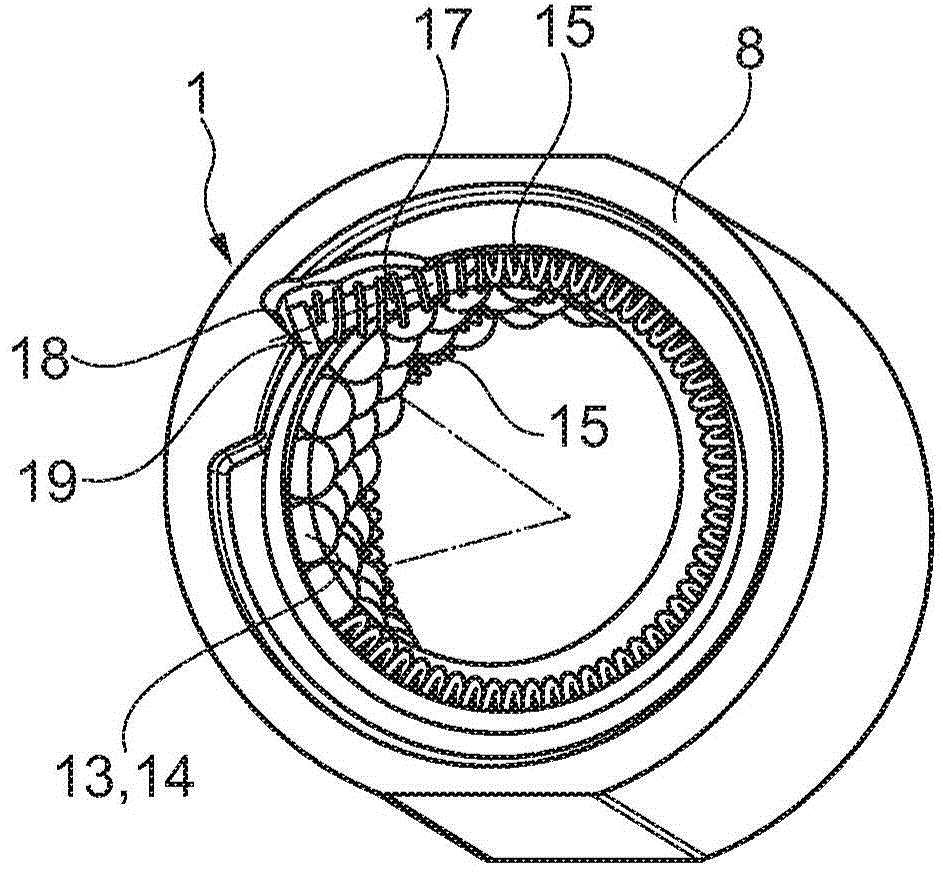

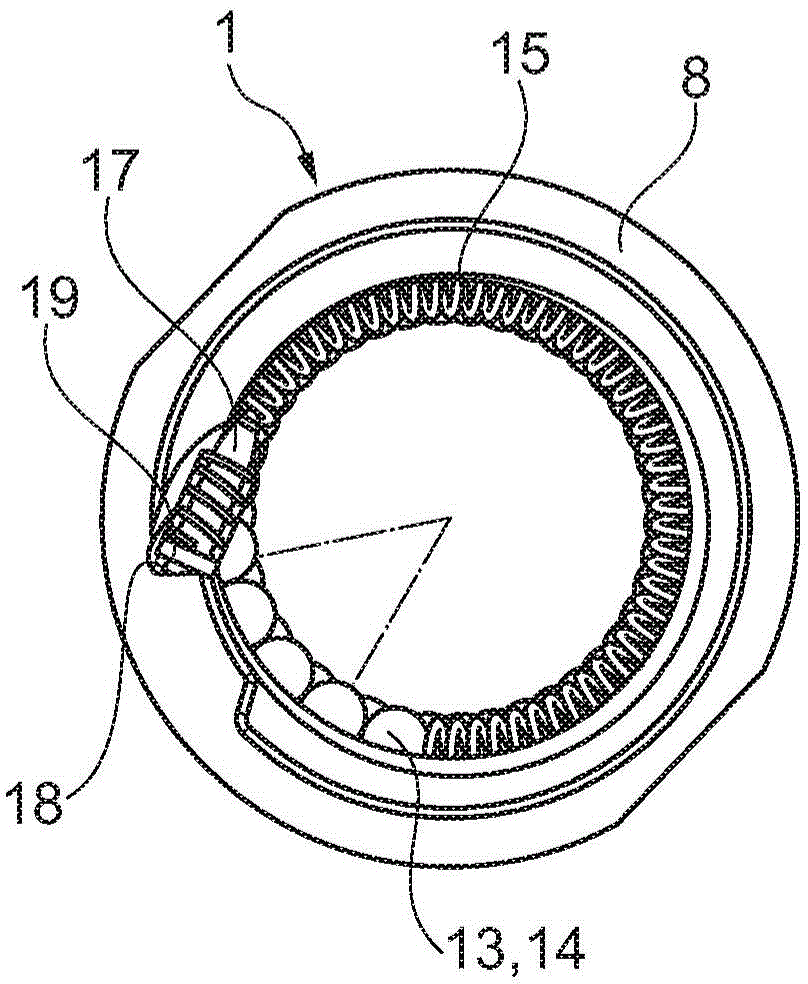

[0026] The ball screw drive 1 according to the invention is arranged in the hollow brake piston 6 . The ball screw drive 1 has a spindle nut 8 arranged on a threaded spindle 7 . To actuate the parking brake, the threaded spindle 7 is rotated by a motor (not shown). In the event of a rotation of the threaded spindle 7 , the spindle nut 8 is displaced axially relative to the threaded spindle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com