Coated and modified anode material and preparation method thereof

A positive electrode material and modification technology, applied in the direction of positive electrode, active material electrode, battery electrode, etc., can solve the problems of structural damage of positive electrode material, safety accident, easy reaction between positive electrode material and electrolyte, etc., to achieve high specific capacity, The effect of stable structure and excellent fast charging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Step 1. Preparation of matrix

[0050] In the above step 1, the matrix is represented by the following formula I:

[0051] LiCo 1-x m x o 2

[0052] Formula Ⅰ

[0053] In the above formula I, the M is one or more of Mg, Al, Mn, Ni, Ca, Zr, Cr, Ti, Cu, Zn, Y, Ce, Mo, Nb, V, P and F .

[0054] In the above formula I, the value range of x is as follows: 0≤x≤0.3.

[0055] In the above step 1, the preparation method of the matrix is not particularly limited, and can be selected according to actual needs and actual conditions.

[0056] In a preferred embodiment, the matrix is prepared by a method comprising the following two steps:

[0057] Step (1), mixing the lithium source, the cobalt source and the M-containing compound, and then sintering the mixed material at 500-1100° C. for 3-20 hours.

[0058] In the above step (1), the lithium source is one or more of lithium carbonate, lithium hydroxide, lithium nitrate and lithium acetate.

[0059] In the above ste...

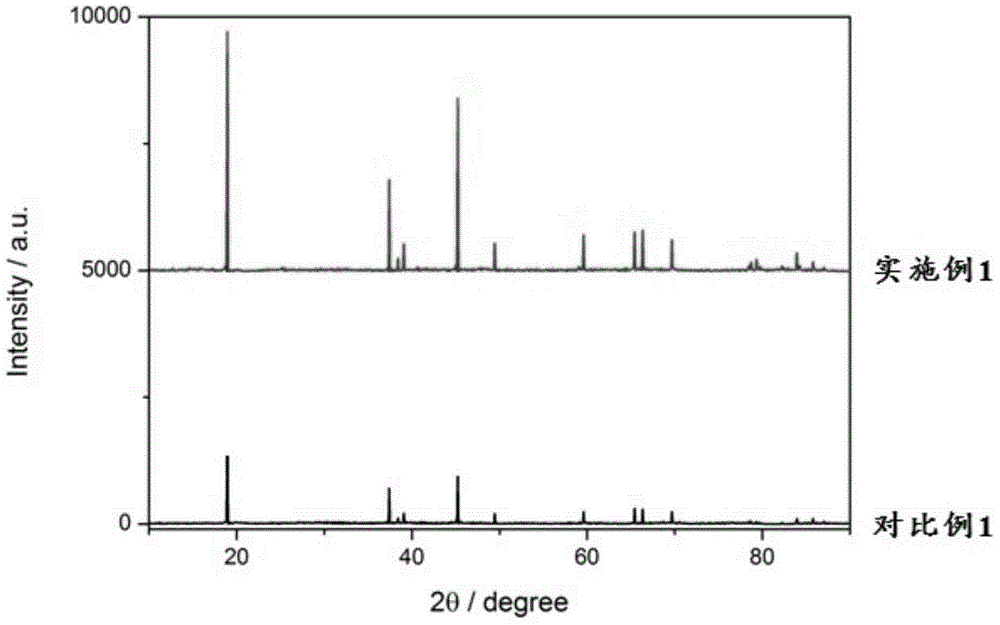

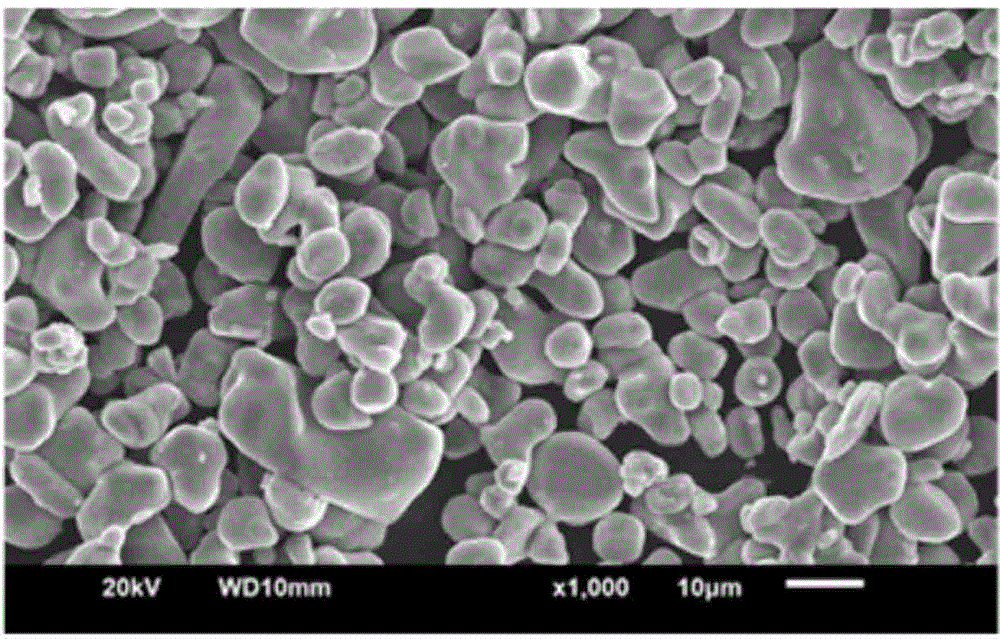

Embodiment 1

[0113] 1. Preparation of matrix

[0114] (1) 75.369g Li 2 CO 3 , 160.53g Co 3 o 4 and 1.509g NiO 2 Ball milling and mixing, after mixing evenly, sinter the mixed material at 1000°C for 12 hours;

[0115] (2) After the sintered mixed material is crushed and passed through a 300-mesh sieve, the matrix LiCo 0.99 Ni 0.01 o 2 .

[0116] 2. Preparation of coated and modified positive electrode materials

[0117] (1) 0.75g tin antimony oxide (mass ratio SnO 2 :Sb 2 o 3 =90:10, D50=10nm) was added into 100mL deionized water to form A solution;

[0118] (2) LiCo prepared in 150g step 1 0.99 Ni 0.01 o 2 After adding to liquid A, stir and disperse evenly, then dry in an oven at 160°C, pass through a 200-mesh sieve, and sinter at 350°C for 4 hours to obtain a coated and modified positive electrode material.

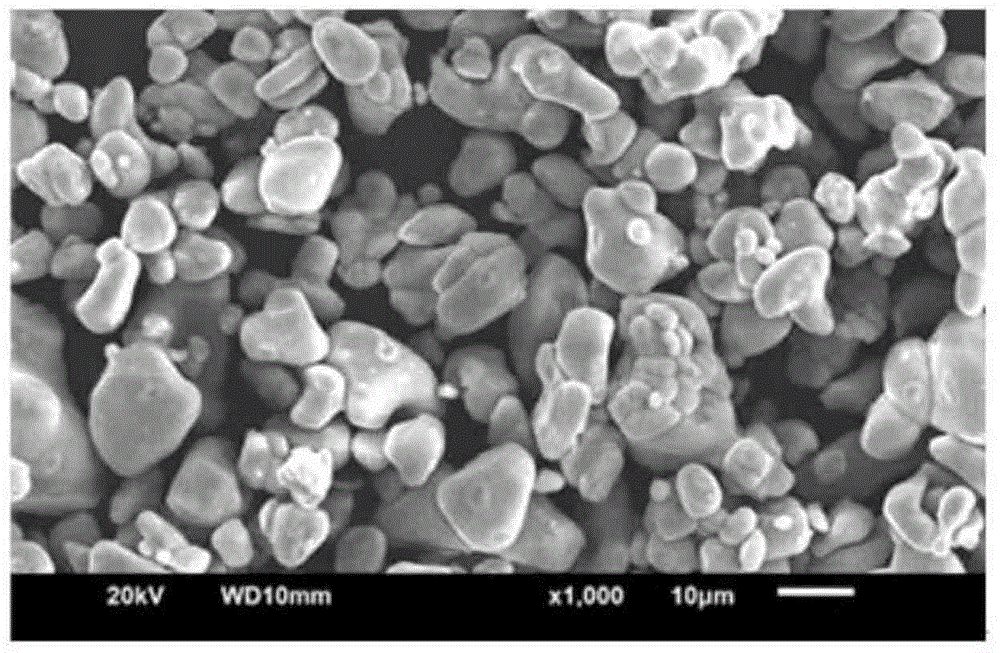

Embodiment 2

[0120] 1. Preparation of matrix

[0121] (1) 49.333g LiOH, 237.884g CoCO 3 and 4.7g Cr 2 o 3 Ball milling and mixing, after mixing evenly, sinter the mixed material at 1000°C for 12 hours;

[0122] (2) After the sintered mixed material is crushed and passed through a 200-mesh sieve, the matrix LiCo 0.97 Cr 0.03 o 2 .

[0123] 2. Preparation of coated and modified positive electrode materials

[0124] (1) 0.75g indium tin oxide (mass ratio In 2 o 3 :SnO 2 =90:10, D50=20nm) was added into 100mL deionized water to form A solution;

[0125] (2) LiCo prepared in 150g step 1 0.97 Cr 0.03 o 2 After adding to liquid A, stir and disperse evenly, then dry in an oven at 120° C., pass through a 200-mesh sieve, and sinter at 350° C. for 4 hours to obtain a coated and modified positive electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com