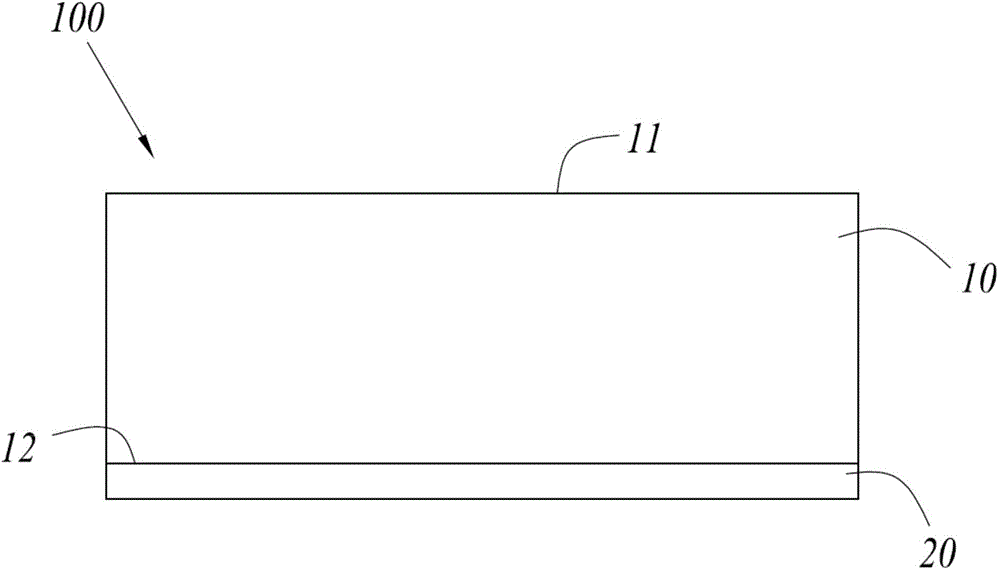

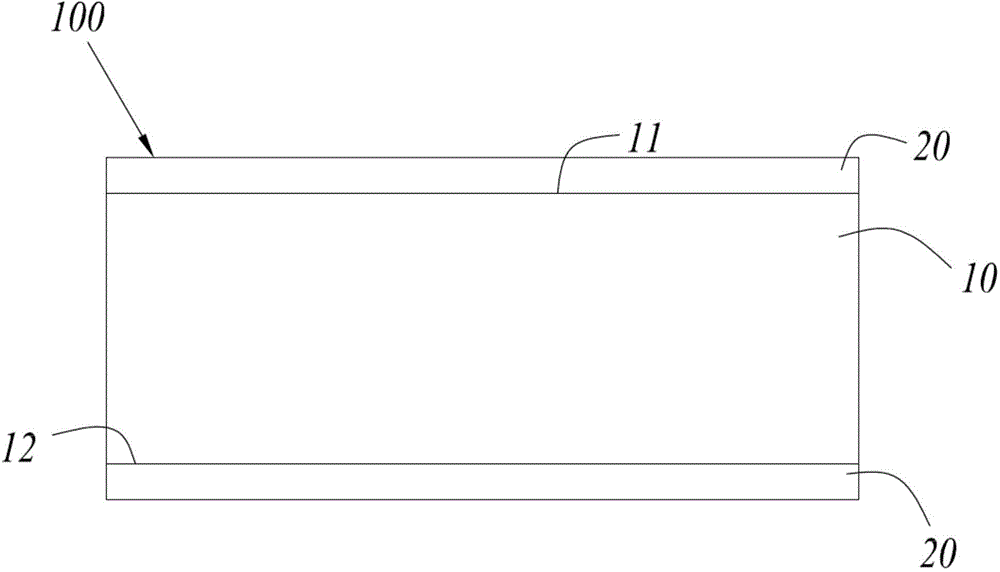

Carbon nano tube composite graphite film for heat dissipation

A carbon nanotube composite and carbon nanotube technology, applied in cooling/ventilation/heating transformation, electrical components, electrical solid devices, etc., can solve problems such as poor thermal conductivity, structural integrity of graphite film and decline in mechanical properties, and achieve Enhanced heat dissipation, superior mechanical properties and flexibility, and improved performance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Highly oriented pyrolytic graphite film is used as the graphite heat conduction layer with a thickness of 1 μm; the carbon nanotube heat dissipation layer contains 20% by weight of carbon nanotubes, 75% by weight of water-based polyurethane, and 5% by weight of additives; The carbon nanotube heat dissipation layer is directly coated on the graphite heat conduction layer by a spraying process, the coating thickness is 10 μm, and baked and dried at 90° C. for 15 minutes to obtain a carbon nanotube composite graphite film for heat dissipation. The surface coated with the carbon nanotube heat dissipation layer was tested by an infrared emissivity tester, and the infrared emissivity was 0.956. The horizontal thermal conductivity of the carbon nanotube composite graphite film for heat dissipation was tested by a laser thermal conductivity meter, which was ~1400W / mK.

Embodiment 2

[0029] Artificial graphite film is used as the graphite heat conduction layer with a thickness of 15 μm; the weight percentage of carbon nanotubes in the carbon nanotube heat dissipation layer is 5%, the weight percentage of water-based acrylic acid is 90%, and the weight percentage of additives is 5%; silk screen is used In the printing process, the carbon nanotube heat dissipation layer is directly coated on the graphite heat conduction layer with a coating thickness of 0.1 μm, and baked and dried at 90° C. for 15 minutes to obtain a carbon nanotube composite graphite film for heat dissipation. The surface coated with the carbon nanotube heat dissipation layer was tested by an infrared emissivity tester, and the infrared emissivity was 0.95. The horizontal thermal conductivity of the carbon nanotube composite graphite film for heat dissipation was measured by a laser thermal conductivity meter, which was ~1400 W / mK.

Embodiment 3

[0031] Natural graphite is used as the graphite heat conduction layer with a thickness of 15 μm; the weight percentage of graphene in the carbon nanotube heat dissipation layer is 10%, the weight percentage of water-based epoxy resin is 85%, and the weight percentage of additives is 5%; the inkjet printing process is adopted The carbon nanotube heat dissipation layer is directly coated on the graphite heat conduction layer with a coating thickness of 10 μm, and baked and dried at 90° C. for 15 minutes to obtain a carbon nanotube composite graphite film for heat dissipation. The surface coated with the carbon nanotube heat dissipation layer was tested by an infrared emissivity tester, and the infrared emissivity was 0.955. The horizontal thermal conductivity of the carbon nanotube composite graphite film for heat dissipation was tested by a laser thermal conductivity meter, which was ~1400W / mK.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com