Super-quick vacuum switch device

A technology of vacuum switch and fast switch, which is applied in the direction of electric switch, high voltage/high current switch, high voltage air circuit breaker, etc. Problems such as large mass of the moving part, to achieve the effect of easy expansion, light moving mass, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

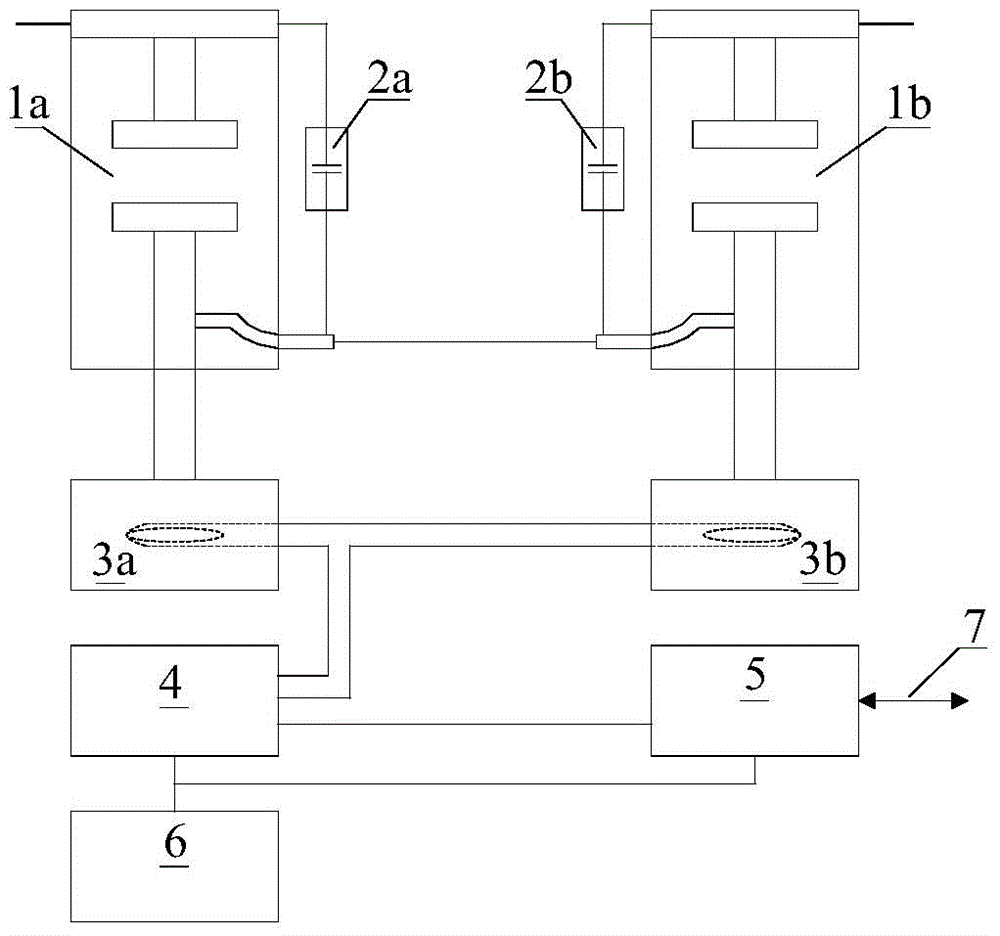

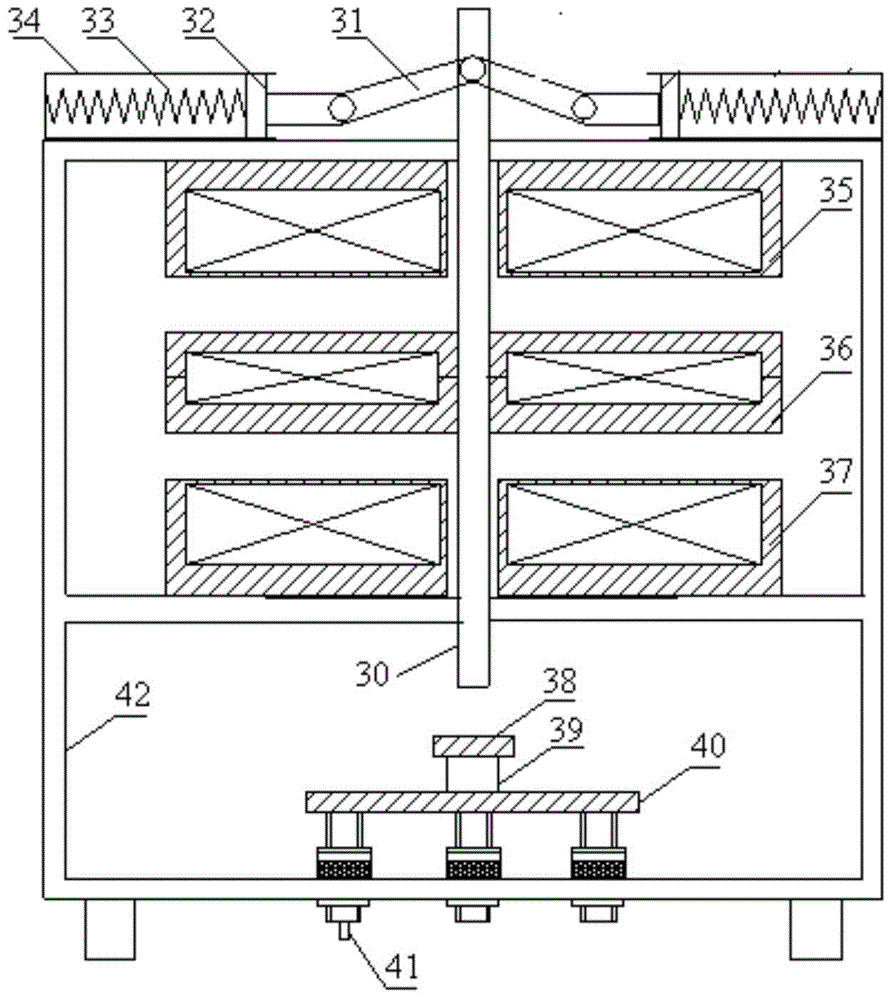

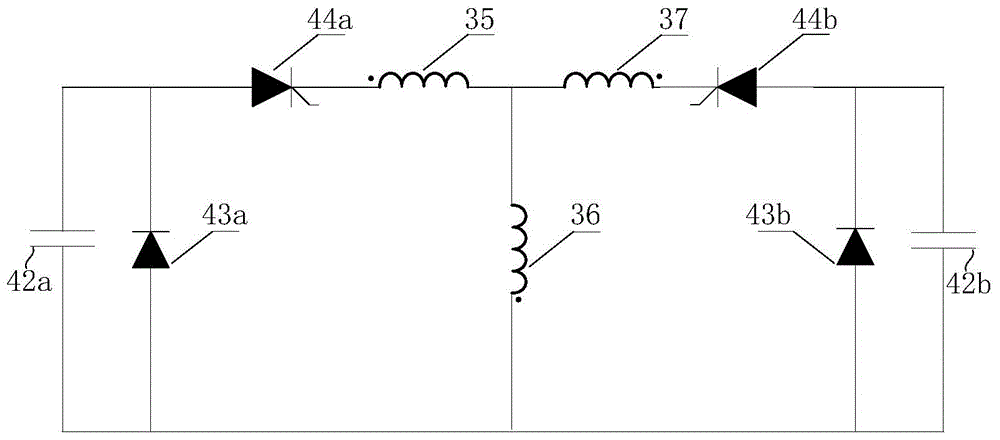

[0018] The specific embodiment of the present invention will be described with reference to the accompanying drawings. Such as figure 1 As shown, the ultra-fast vacuum switchgear includes two to four ultra-fast vacuum switch modules connected in series, including a first epoxy-sealed vacuum pole 1a and a second epoxy-sealed vacuum pole 1b, a first pressure equalizing device 2a and the second equalizing device 2b, the first operating mechanism 3a and the second operating mechanism 3b, the pulse current generator 4, the fast switch controller 5, the isolated auxiliary power supply 6 and the optical fiber 7;

[0019] The first operating mechanism 3a and the second operating mechanism 3b are respectively located under the first epoxy-embedded vacuum pole 1a and the second epoxy-embossed vacuum pole 1b, and are equipotentially connected; The first voltage equalizing device 2a and the second voltage equalizing device 2b are voltage equalizing circuits in which capacitors and resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com