Mode locking free oil cylinder hydraulic mode-locking plastic jetting-moulding machine

The technology of clamping cylinder and hydraulic lock is applied in the field of hydraulic clamping device without clamping cylinder. The effect of uniform distribution of force and compact structure of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

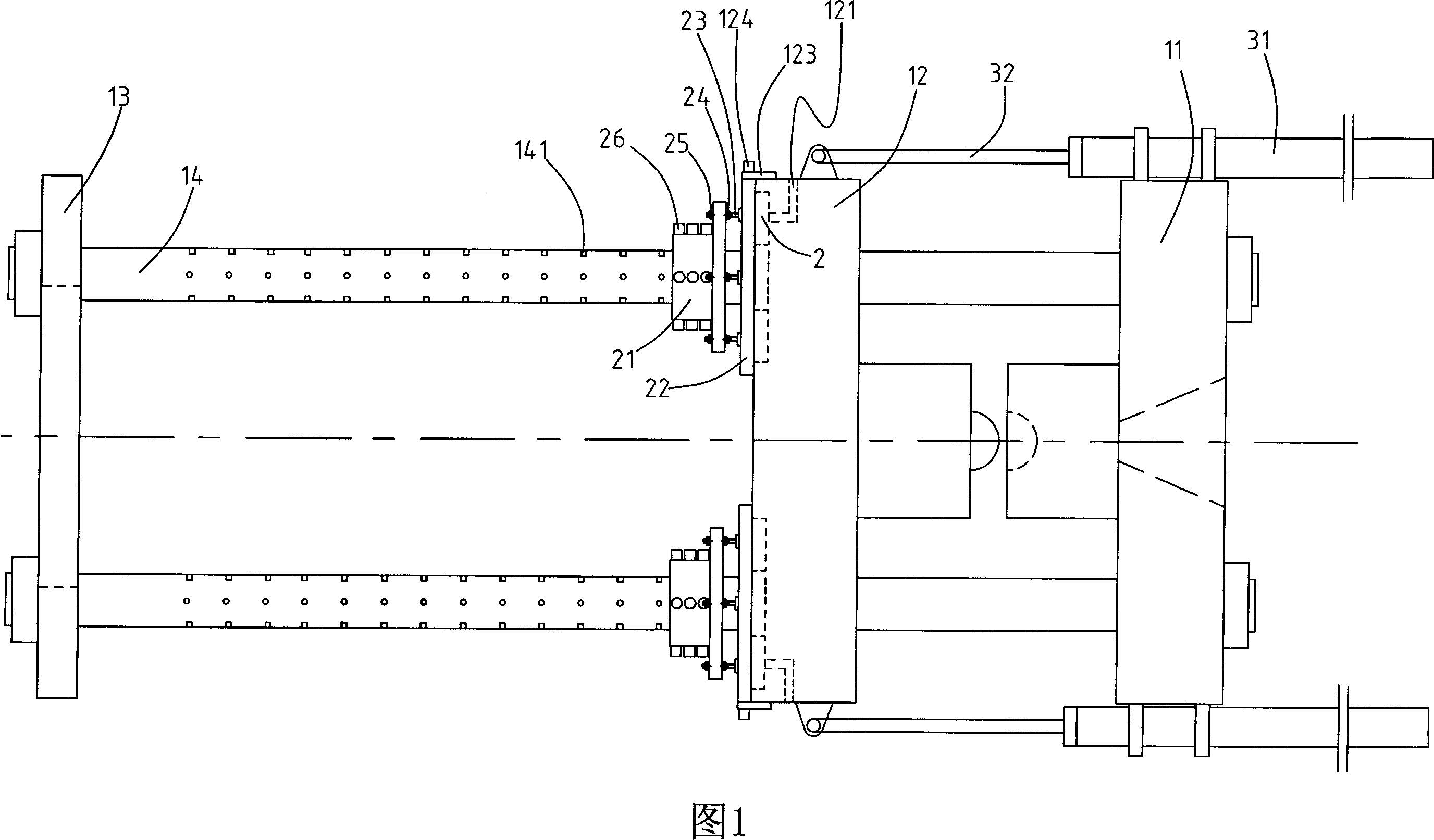

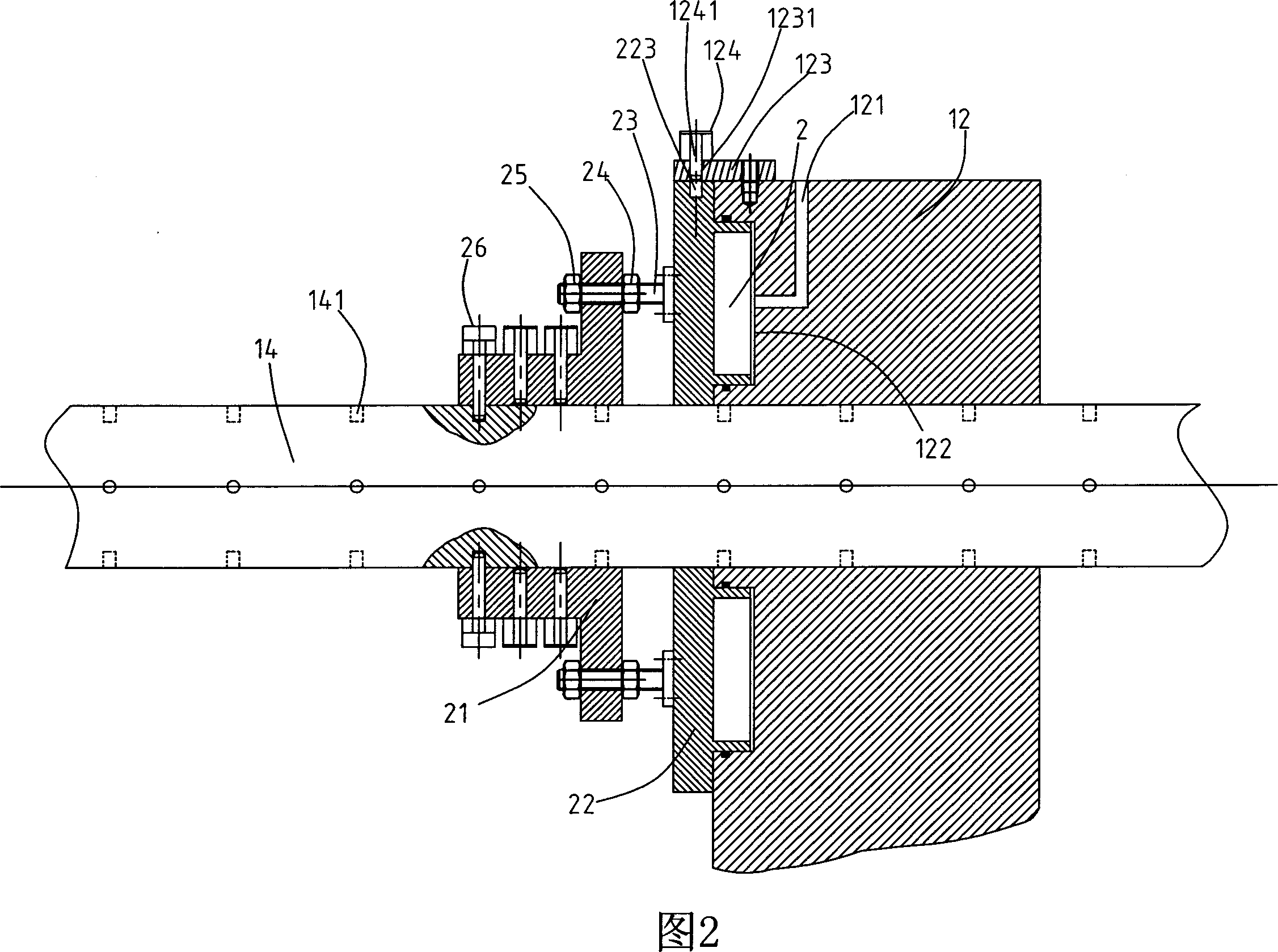

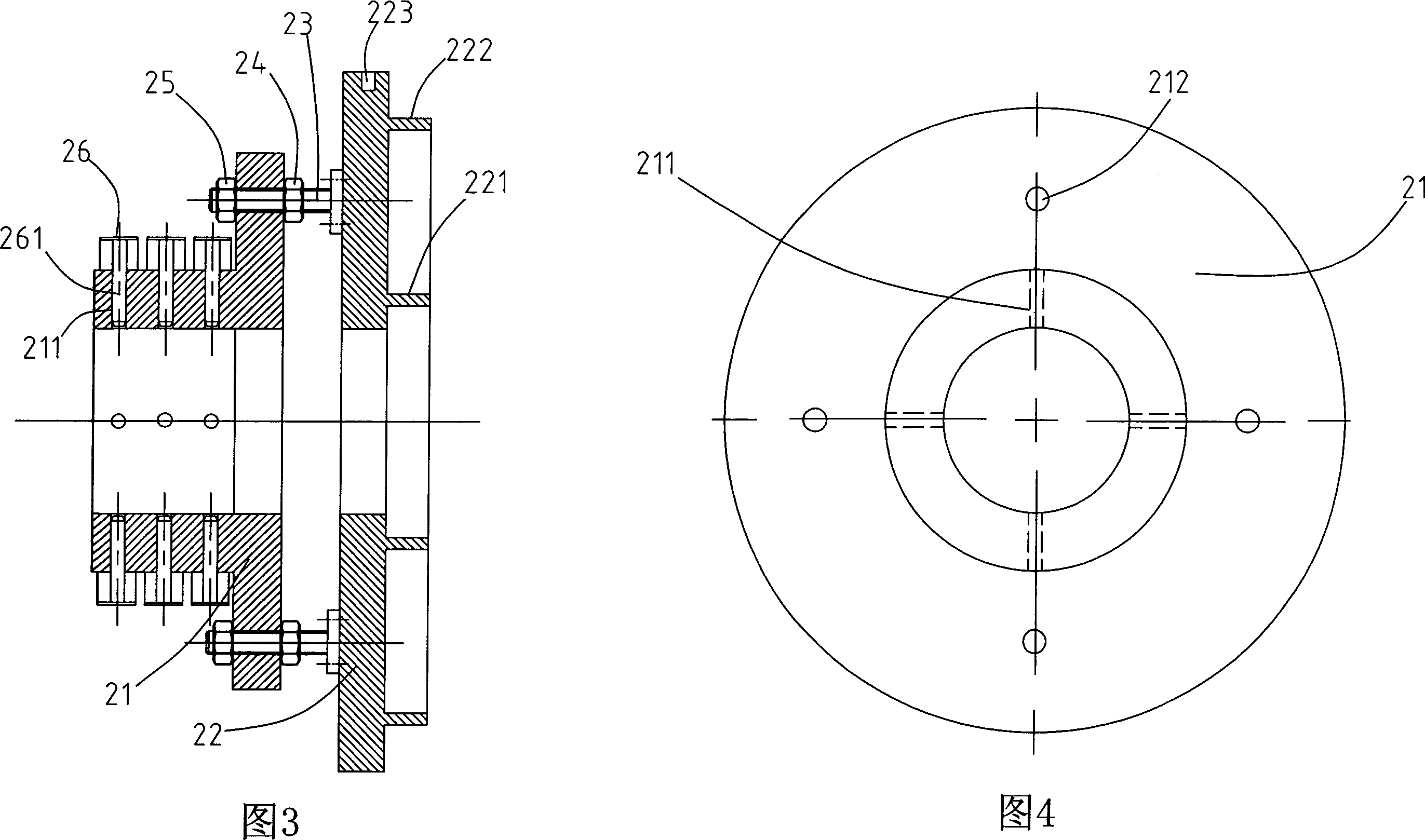

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] As shown in Figures 1 to 8, it is a hydraulic clamping injection molding machine without a clamping cylinder, which includes a fixed platen 11, a movable platen 12, and a rear platen 13, which pass through the two ends of the movable platen to connect with the fixed platen and the rear platen respectively. The fixed tie rod 14, the free positioning mold locking group composed of the stepped sleeve 21 and the end cover 22, and the quick mold moving cylinder 41. The pull rod 14 is provided with more than one row of radially symmetrically distributed first pin holes 141 distributed along the axial direction; On the pull rod 14, the stepped sleeve and the end cover are tightly connected by bolts 23 and two nuts 24, 25. One end of the bolt is fixed on the end cover 22 and the other end passes through the through hole opened at the base of the stepped sleeve and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com