3D information-based automatic fault identification and detection system and detection method

An automatic identification and detection system technology, applied in character and pattern recognition, instruments, calculations, etc., can solve the problems of increasing the workload and difficulty of manual confirmation, affecting the efficiency of vehicle inspection, and large workload, and improving the accuracy of automatic identification. efficiency, ensure the detection accuracy, and improve the efficiency of vehicle inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

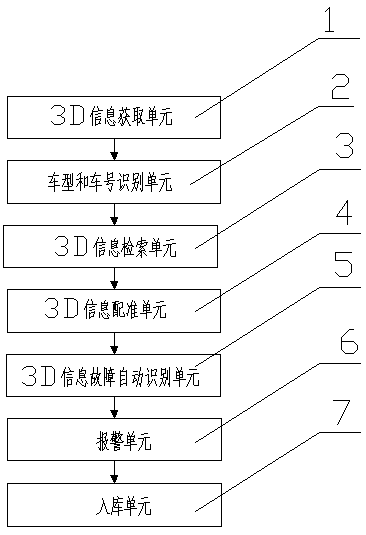

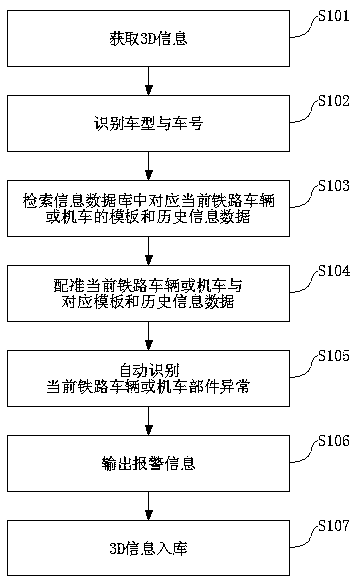

[0021] An automatic fault identification and detection system based on 3D information, its composition includes: an automatic fault identification and detection system based on 3D information, its composition includes: a 3D information acquisition unit, and the 3D information acquisition unit is electrically connected to the vehicle type and vehicle number identification unit connected, the vehicle type and car number identification unit is electrically connected to the 3D information retrieval unit, the 3D information retrieval unit is electrically connected to the 3D information registration unit, and the 3D information registration unit is electrically connected to the 3D information fault automatic identification unit Electrically connected, the 3D information fault automatic identification unit is electrically connected to the alarm unit, and the alarm unit inputs signals to the storage unit, and further detects, controls and processes the locomotive operation according to ...

Embodiment 2

[0023] According to the 3D information-based automatic fault identification and detection system described in Embodiment 1, the 3D information acquisition unit is used to acquire 3D information at various angles of railway vehicles and locomotives, including three-dimensional space information and grayscale information; the vehicle type And car number recognition unit, utilize 3D information to identify and obtain the vehicle type and the car number of railway vehicle and locomotive; Described 3D information retrieval unit utilizes 3D information retrieval to obtain various templates and historical data information corresponding to the current vehicle passing; The above-mentioned 3D information registration unit uses 3D information to register various templates and historical data information corresponding to the current vehicle passing; the above-mentioned 3D information automatic fault identification unit uses 3D information feature recognition to obtain whether there is abnor...

Embodiment 3

[0025] According to the 3D information-based automatic fault identification and detection system described in Embodiment 1 or 2, the 3D information acquisition unit acquires 3D information from various angles of the current passing vehicle, and the same component can obtain different 3D information from several angles; each Each 3D information unit contains three-dimensional space information and grayscale information; the 3D information unit of each template in the information database contains three-dimensional space information and grayscale information, and the vehicle type and specific vehicle are identified according to the three-dimensional space information in the obtained 3D information; Obtain grayscale information in 3D information to identify vehicle models and specific vehicles; identify vehicle models and specific vehicles based on acquired 3D space information and grayscale information in 3D information; combine 3D information with existing two-dimensional image v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com