Method for Improving the Hydrogen Analysis and Detection Rate of Hydrogen Production and Carbon Monoxide Devices

A carbon monoxide and hydrogen production technology, applied in measurement devices, analytical materials, instruments, etc., can solve the problems of not meeting customer safety requirements, not shortening the time of interlocking action, etc., to achieve the effect of improving response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

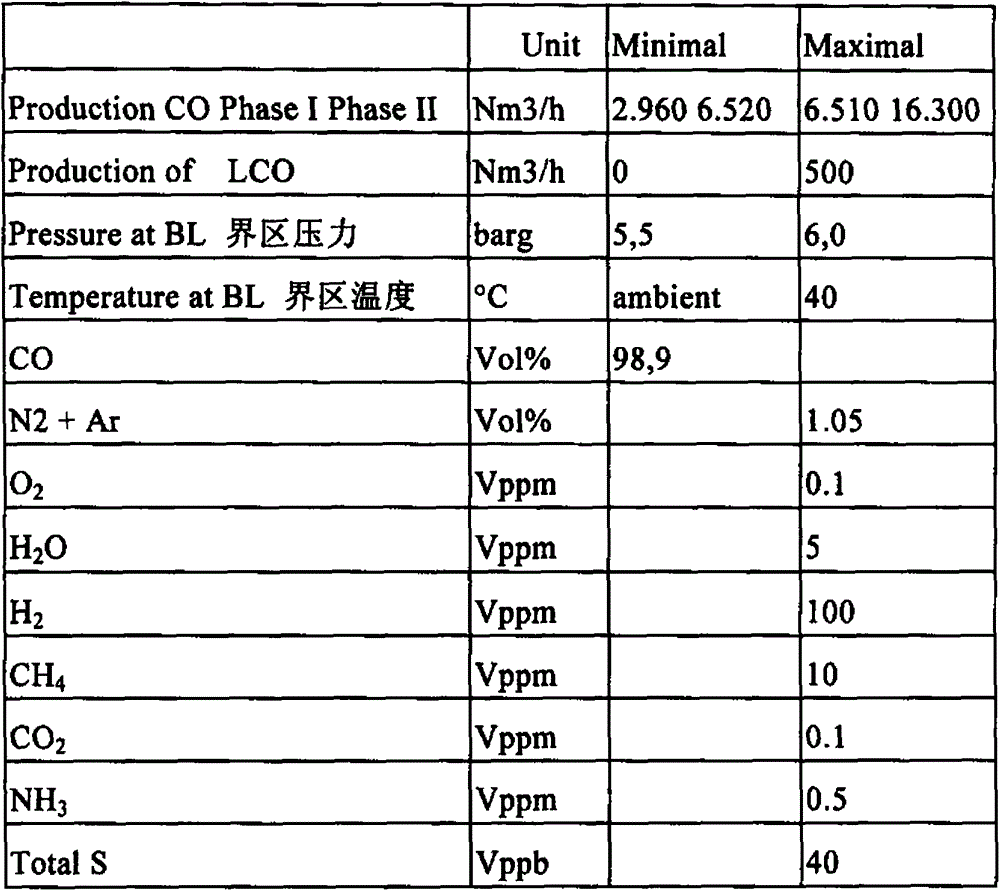

[0019] A method for improving the hydrogen analysis and detection rate of hydrogen and carbon monoxide production equipment. This method is used to detect the content of water, methane, hydrogen and carbon monoxide in CO products. Three hydrogen analyzers are installed in the output section of the detection device, which are 3- 1711AT050.1, 3-1711AT050.2, 3-1711AT050.3, the above-mentioned hydrogen analyzer is connected to the sampling pipeline, and the subsequent pipeline is equipped with a quick shut-off valve. There is a fast loop, the interlock value of the hydrogen analyzer is 10000Vppm, and the alarm value is 1000Vppm. Change the original sampling tube with a diameter of 12mm to a sampling tube with a diameter of 6mm, because the sample gas injection volume of the online analyzer is a fixed amount, and the factor that affects the response time of the analyzer is only the distance between the process pipeline and the analyzer. The amount of sample gas in the sample line. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com