A rebound rebound instrument with an auxiliary measuring device

A technology of auxiliary measurement and auxiliary device, which is applied in the direction of testing material hardness, etc., can solve the problems of reducing the durability and measurement accuracy of the instrument, affecting the adjustment of the impact plane and the hammer body, and the slow measurement speed of the rebound instrument, so as to save physical strength, The effect of increasing friction and making it easier to exert force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

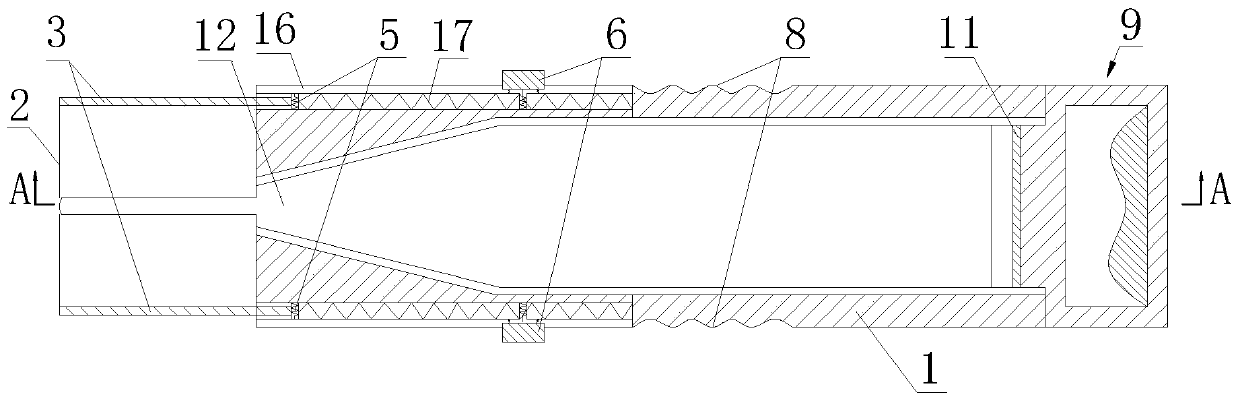

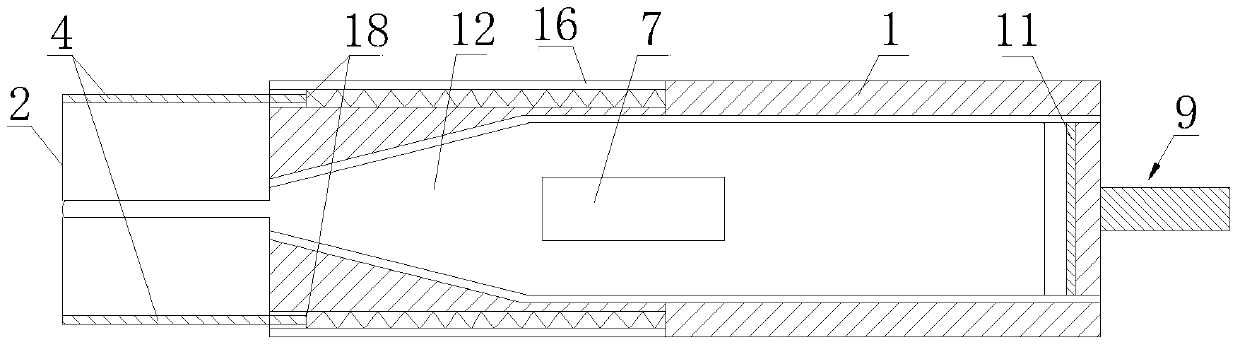

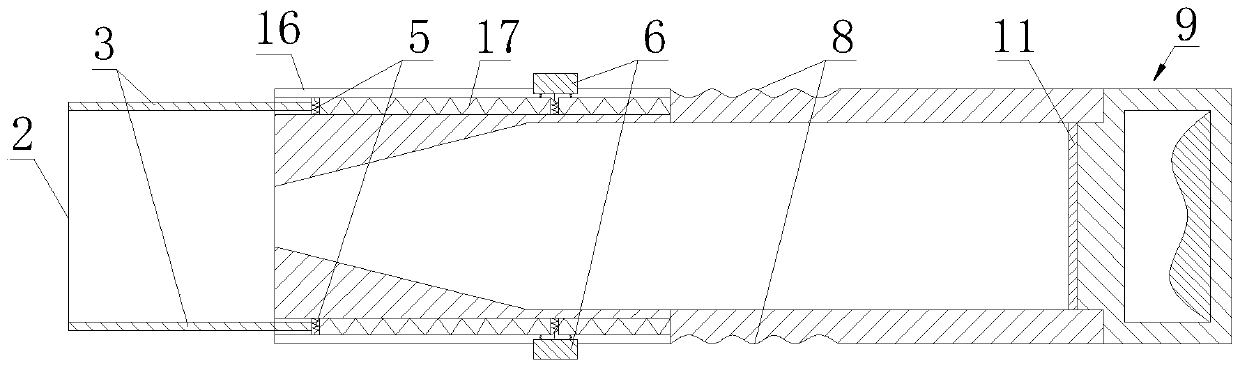

[0031] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0032] like Figure 1 to Figure 9 As shown, a rebound hammer with an auxiliary measuring device according to the present invention includes a rebound hammer main body 12 and an auxiliary device set outside the rebound hammer main body 12, and the auxiliary device consists of a circular casing 1 and a set The conduit 16 on the upper part of the circular casing 1 is composed of a circular flat plate 2 arranged at the top of the circular casing 1, and a positioning mechanism and a guiding mechanism connected with the circular flat plate 2 are respectively arranged in the conduit 16. The positioning mechanism includes two telescopic positioning rods 3 symmetrically arranged on the circular flat plate 2, and the ends of the two telescopic positioning rods 3 far away from the circular flat pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com