Rubber vibration isolator for rail transit floating slab track bed vibration isolation system

A technology of rubber vibration isolator and vibration isolation system, which is applied in the field of vibration reduction and noise reduction, can solve the problems that the processing technology and technical level are not recognized by the industry, easily cause system resonance, and dense natural frequency, so as to achieve a good appearance and facilitate batch production The effect of streamlining production, improving bearing capacity and anti-fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

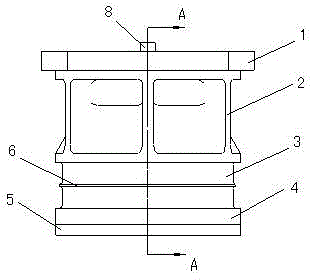

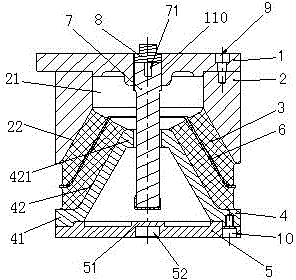

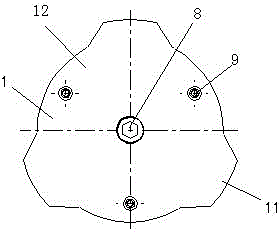

[0028] see figure 1 , with reference to figure 2 , image 3, the present invention is used for the rubber vibration isolator of the rail transit floating slab ballast bed vibration isolation system, including the upper cover plate 1, the upper iron part 2, the rubber part 3, the lower iron part 4 and the lower seat plate 5 connected in sequence, and the iron Core 6, limit bolt 7 and locking screw plug 8; iron core 6 is set in the rubber part 3 and vulcanized into one with the rubber part, and the limit bolt 7 passes through the upper cover plate 1, the upper iron part 2 and the rubber part in sequence 3 and the lower iron piece 4, and are threaded with the upper cover plate 1, and the locking screw plug 8 is threaded with the upper cover plate, and abuts against the top surface of the limit bolt 7 to lock the limit bolt. The upper cover plate 1 and the upper iron part 2 are detachably connected by bolts 9, the upper iron part 2, the lower iron part 4 and the rubber part 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com