A Dyeing and Finishing Process for Cotton Knitting for Special Purposes

A special-purpose, cotton knitting technology, applied in two or more different solvent-based treatment materials, dyeing methods, textiles and papermaking, etc. Problems such as poor perspiration, to achieve the effect of improving product style, improving ventilation and heat dissipation, and strengthening market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The purpose of the present invention is to design a dyeing and finishing process of all-cotton knitted cloth for military products with simple operation, environmental protection, good color fastness, good dry and wet rubbing fastness, and good bursting strength of gray cloth. The technical scheme of the present invention is as follows Achieved:

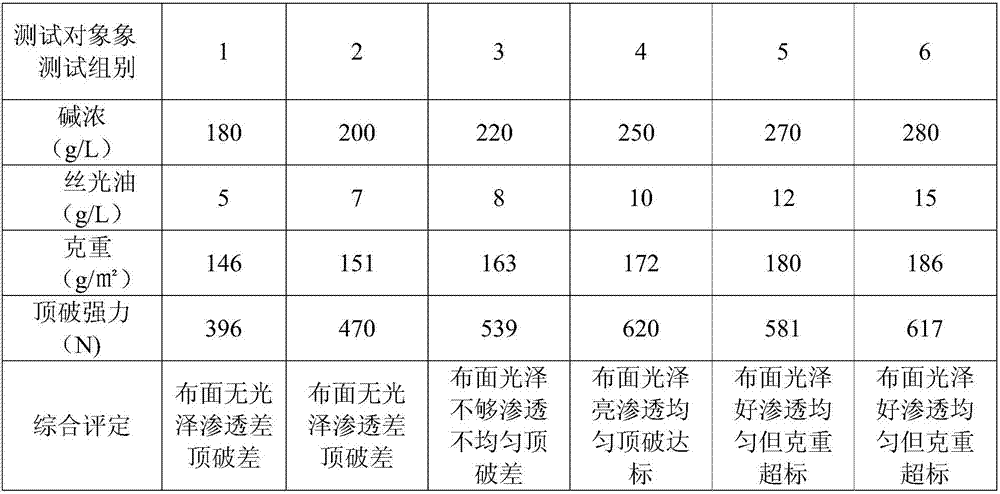

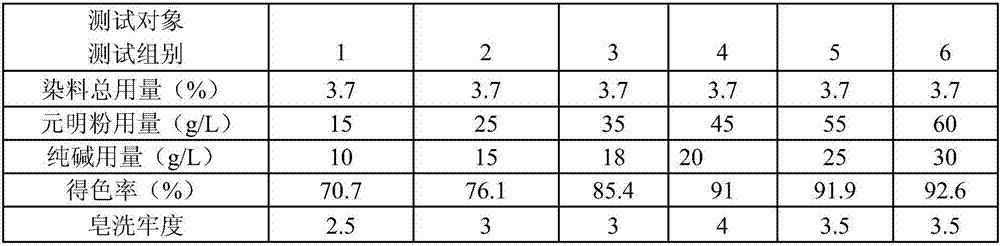

[0024] For the dyeing and finishing process of cotton knitted fabric, the gray fabric is 50S / 1 cotton double-sided fabric, which requires an effective width of 140cm and a weight of 185g / ㎡. Dry friction level 4, wet friction level 3, soaping fastness level 4, More than 500N strong, specifically include the following steps:

[0025] a) Selection of gray fabric: select 50S Xinjiang combed long-staple cotton yarn, and select all-cotton double-sided fabric woven by Taiwan double-sided large circular machine;

[0026] b) Singeing: Singeing on both sides by German Ostov knitting singeing machine;

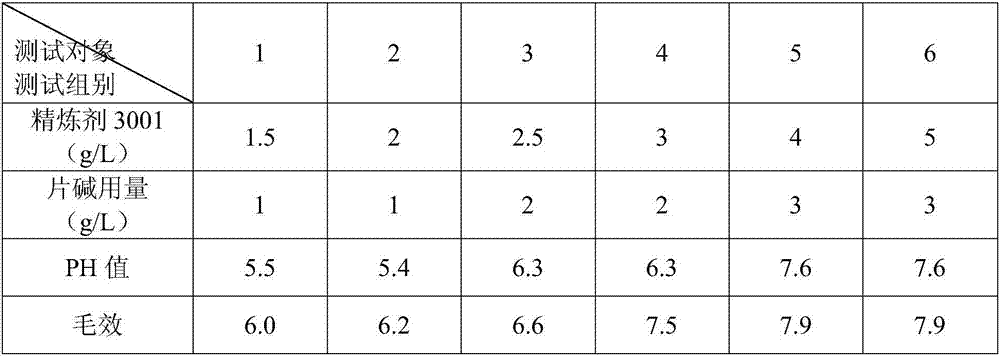

[0027] c) Pretreatment: scouring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com