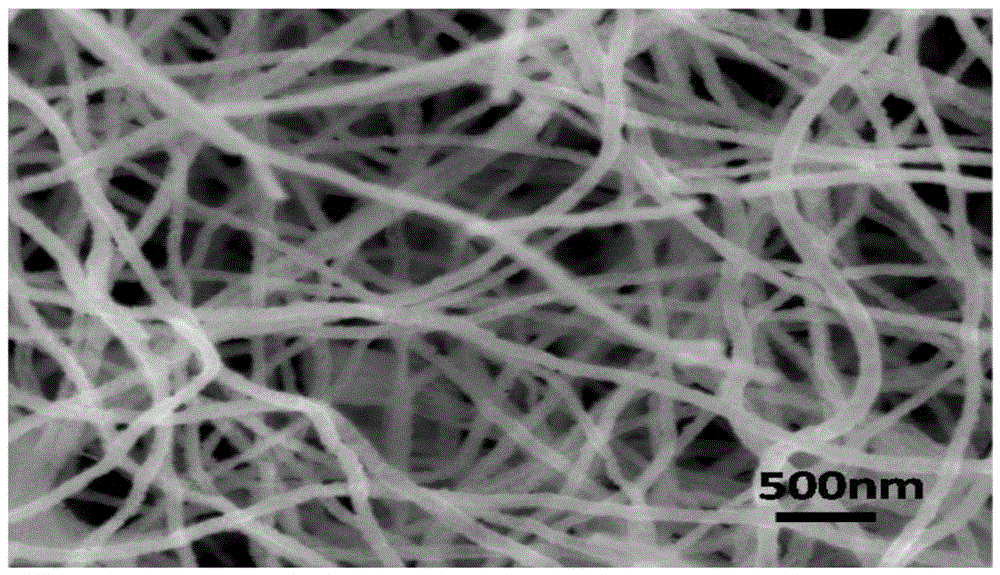

Preparation method of porous carbon nanofiber

A nanofiber, porous carbon technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of low effective utilization area of carbon nanofibers, and achieve the effects of low cost, simple process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of porous carbon nanofibers, specifically comprising the following steps:

[0030] (1) Weigh polyacrylonitrile and polyvinylpyrrolidone according to the mass ratio of 1:2, add them to the dimethylformamide solvent, the mass fractions of the two polymers are 10% and 20% respectively, stir magnetically for 24 hours, and the magnetic stirring speed Be 100r / min, obtain spinning precursor liquid;

[0031] (2) Spinning precursor liquid is injected into the syringe that has spinneret, then syringe is fixed on the propulsion pump; Spinning voltage U=15kV is set, the distance L=15cm between receiver and spinneret, propulsion rate R=1mL / h, start electrospinning, and the spun fibers are received by the receiver to obtain nanofibers;

[0032] (3) Preoxidize the nanofibers in an air atmosphere, the preoxidation temperature is 280° C., preoxidize for 2 hours, and the heating rate is 1° C. / min to obtain preoxidized nanofibers;

[0033] (4) Carbonize the pre-oxid...

Embodiment 2

[0036] A preparation method of porous carbon nanofibers, specifically comprising the following steps:

[0037] (1) Weigh phenolic resin, polyimide, and polyvinylpyrrolidone according to a mass ratio of 1:1:2, and add them to a mixed solvent of dimethylformamide and ethanol. The mass fractions of the three polymers are 10%, 10%, and %, 20%, magnetically stirred for 30 hours, and the rate of magnetically stirred is 800r / min, to obtain the spinning precursor;

[0038] (2) Spinning precursor liquid is injected into the syringe that has spinneret, then syringe is fixed on the propulsion pump; Setting voltage U=12.5kV, distance L=14cm between receiver and spinneret, propulsion rate R =2mL / h, start electrospinning, the spun fibers are received by the receiver to obtain nanofibers;

[0039] (3) Preoxidize the nanofibers in an air atmosphere, the preoxidation temperature is 250°C, the preoxidation time is 3h, and the heating rate is 3°C / min, to obtain preoxidized nanofibers;

[0040]...

Embodiment 3

[0043] A preparation method of porous carbon nanofibers, specifically comprising the following steps:

[0044] (1) Weigh polyaniline and polyoxyethylene according to the mass ratio of 2:1, add them into chloroform, and the mass fractions of the two polymers are 4% and 2% respectively, and magnetically stir for 36h, and the speed of magnetic stirring is 400r / min to get the spinning precursor solution.

[0045] (2) Spinning precursor liquid is injected into the syringe that has spinneret, then syringe is fixed on the propulsion pump; Spinning voltage U=20kV is set, the distance L=20cm between receiver and spinneret, propulsion rate R=8mL / h, start electrospinning, and the spun fibers are received by the receiver to obtain nanofibers;

[0046] (3) Preoxidize the nanofibers in an air atmosphere, the preoxidation temperature is 300°C, the preoxidation time is 3h, and the heating rate is 5°C / min, to obtain preoxidized nanofibers;

[0047] (4) Carbonize the pre-oxidized nanofibers ...

PUM

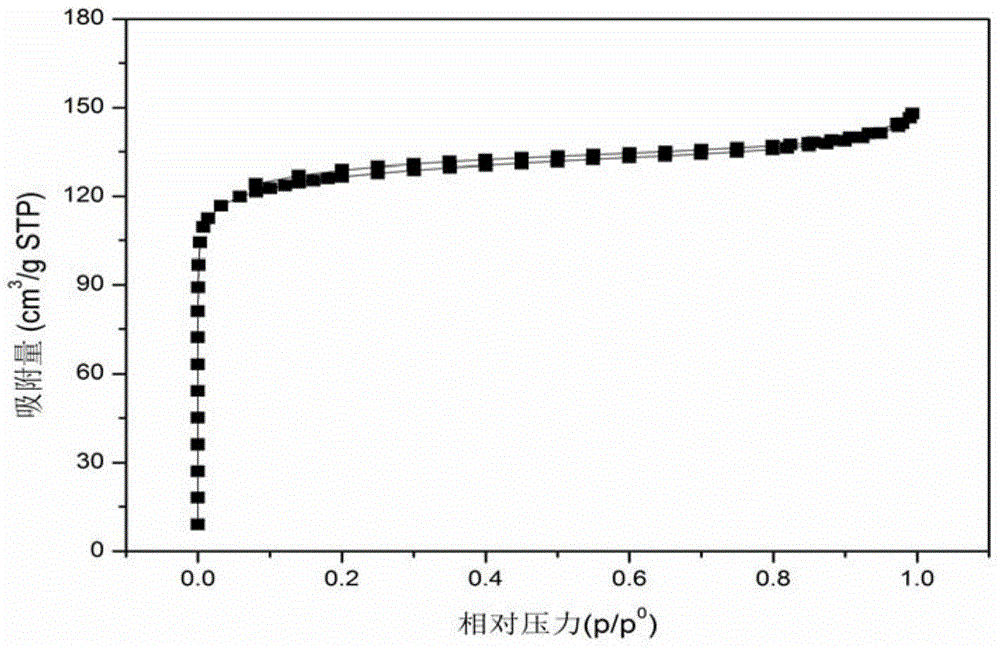

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com