A processing device for raw ecological brown sugar

A processing device and original ecological technology, applied in the production of sugar, purification of sugar juice, sugar crystallization, etc., can solve the problem of high impurities in brown sugar, and achieve the effects of high nutritional value, small grain size and high level of industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

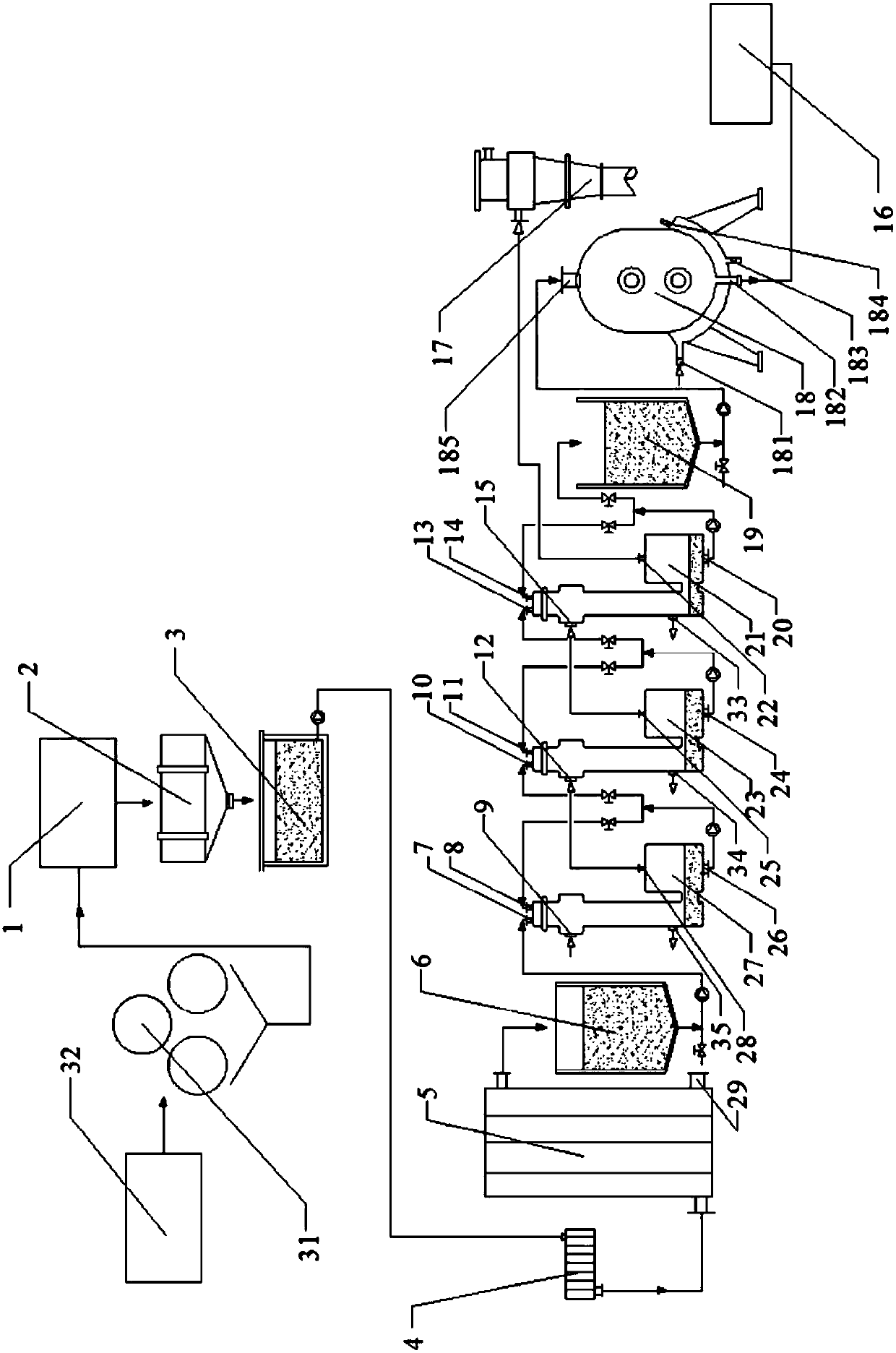

[0032] A processing device for raw ecological brown sugar, including sequentially connected pressing coarse filtration equipment, heat exchanger 4, multi-stage ceramic membrane ultrafiltration equipment 5, falling film type three-effect vacuum evaporation system, water jet condenser 17, interlayer iron Pot 18 and crystal drying and forming equipment.

[0033] A clarified sugarcane juice box 6 is connected between the multistage ceramic membrane ultrafiltration equipment 5 and the three-effect vacuum evaporation equipment;

[0034] A syrup box 19 is connected between the falling film type three-effect vacuum evaporation system and the interlayer iron pan;

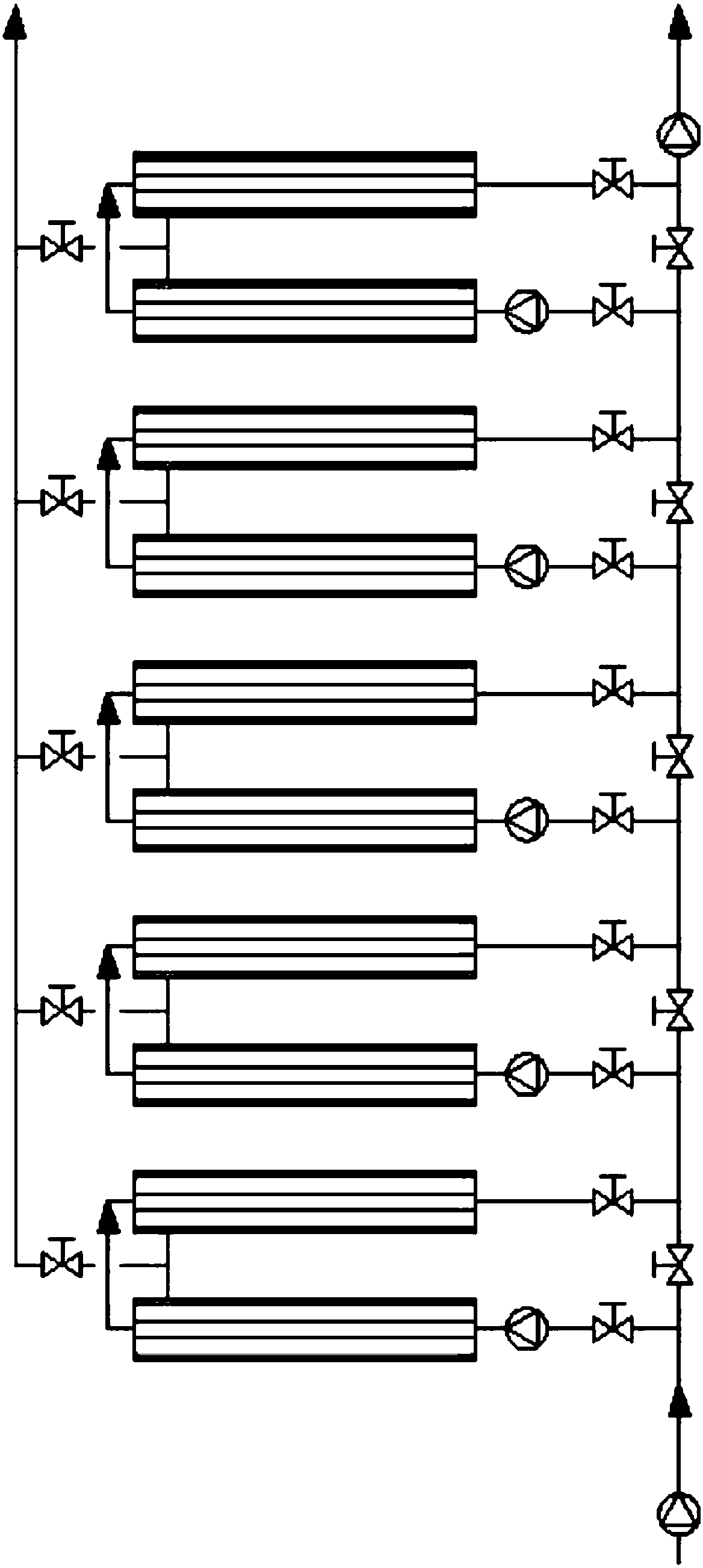

[0035] The falling-film three-effect vacuum evaporation system includes a falling-film one-effect vacuum evaporator 27 , a falling-film two-effect vacuum evaporator 23 and a falling-film three-effect vacuum evaporator 21 .

[0036] The specific connection method is as follows:

[0037] The outlet of the coarsely filtered s...

Embodiment 2

[0045] This embodiment is a specific example of using the original brown sugar processing device of the present invention to produce, and the specific operation steps are:

[0046] (1) Squeeze and extract juice and coarsely filter: Send the sugarcane into a tearing machine to tear it into filaments, sheets, strips and other sugarcane materials, and then send it to a three-roll press to extract juice. In order to increase the juice yield, you can go to the second Spray a small amount of water on the bagasse obtained after the first juicing, and then squeeze the juice again to obtain sugarcane juice for later use; first, the sugarcane juice is beaten and filtered by a pulper with a 0.1 mm aperture, and then passed through a sieve with a 400-mesh aperture. Type centrifuge to further filter, thereby removing large particles of impurities such as sugarcane bran and sugarcane debris in the sugarcane juice, and obtaining coarsely filtered sugarcane juice for later use;

[0047] (2) H...

Embodiment 3

[0055] This embodiment is another specific example of using the original brown sugar processing device of the present invention for production, and the specific operation steps are:

[0056] (1) Squeeze and extract juice and coarsely filter: Send the sugarcane into a tearing machine to tear it into filaments, sheets, strips and other sugarcane materials, and then send it to a three-roll press to extract juice. In order to increase the juice yield, you can go to the second Spray a small amount of water on the bagasse obtained after the first juicing, and then squeeze the juice again to obtain sugarcane juice for later use; first, the sugarcane juice is beaten and filtered by a pulper with a 0.1 mm aperture, and then passed through a sieve with a 400-mesh aperture. Type centrifuge to further filter, thereby removing large particles of impurities such as sugarcane bran and sugarcane debris in the sugarcane juice, and obtaining coarsely filtered sugarcane juice for later use;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com