A kind of fertilizer-increasing and water-retaining liquid mulch film and its preparation method

A technology of liquid mulch and fertilizer, applied in fertilization devices, fertilizer mixtures, plant protection covers, etc., can solve problems such as poor film performance, and achieve the effects of reducing bulk density, improving utilization, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

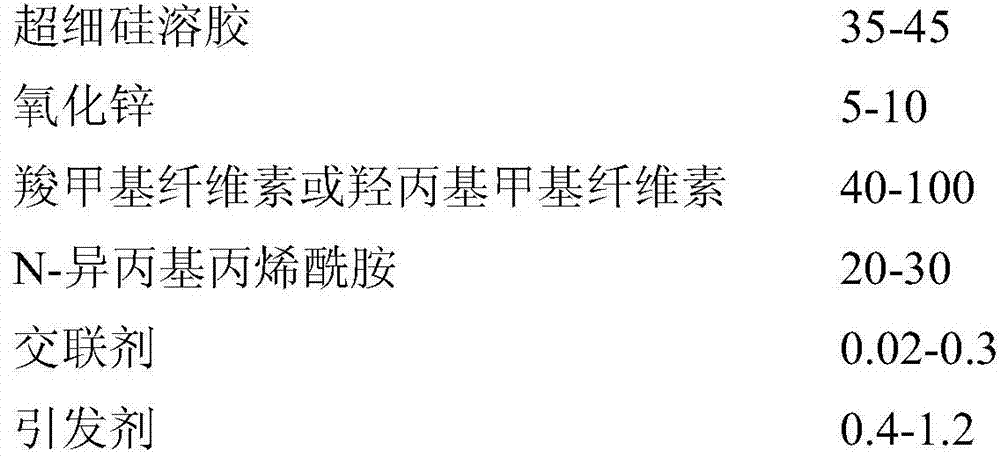

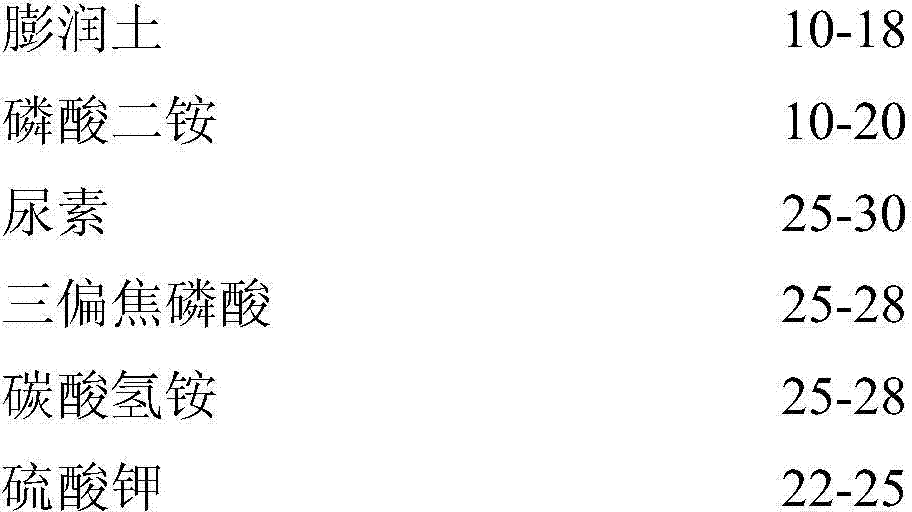

Method used

Image

Examples

Embodiment 1

[0044] Preparation of ultrafine silica sol: After diluting and dissolving sodium silicate in water, ultrasonically oscillate for 20 minutes and mix evenly to form a water glass solution with a concentration of 30wt%. 2 Mix to obtain composite resin; fully stir and mix the water glass solution and the composite exchange resin according to the weight ratio of 20:1, remove impurities, and obtain a pretreated silicic acid solution; add alkali solution to the silicic acid solution, and adjust the pH value to 9.5, The silica sol mother liquor was obtained after heating and reacting at 70°C under normal pressure for 2 hours; the silica sol mother liquor was dehydrated, concentrated and purified to prepare a silica sol with a concentration of 20 wt%, wherein the silica particle size was between 1-100nm.

[0045] At room temperature, add 4 g of carboxymethyl cellulose to deionized water, stir until completely dissolved under the protection of nitrogen, then add 2 g of 20 wt% superfine s...

Embodiment 2

[0048] Preparation of ultra-fine silica sol: After diluting and dissolving sodium silicate in water, ultrasonically oscillate for 10 minutes and mix evenly to form a water glass solution with a concentration of 25 wt%. 3 Mix to obtain composite resin; fully stir and mix the water glass solution and the composite exchange resin at a weight ratio of 40:1, remove impurities, and obtain a pretreated silicic acid solution; add alkali solution to the silicic acid solution, and adjust the pH value to 9, After heating and reacting at 85°C under normal pressure for 1 hour, the silica sol mother liquor was obtained; the silica sol mother liquor was dehydrated, concentrated and purified to prepare a silica sol with a concentration of 20 wt%, wherein the silica particle size was between 1-100nm.

[0049] At room temperature, add 5 g of carboxymethyl cellulose to deionized water, stir until completely dissolved under nitrogen protection, then add 1 g of 20 wt% superfine silica sol solution ...

Embodiment 3

[0052] Preparation of ultra-fine silica sol: After diluting and dissolving sodium silicate in water, ultrasonically oscillate for 15 minutes and mix evenly to form a water glass solution with a concentration of 15 wt%. 2.5 Mix to obtain the composite resin; fully stir and mix the water glass solution and the composite exchange resin at a weight ratio of 30:1, remove impurities, and obtain a pretreated silicic acid solution; add alkali solution to the silicic acid solution, and adjust the pH value to 10, After heating and reacting at 80°C under normal pressure for 3 hours, the silica sol mother liquor was obtained; the silica sol mother liquor was dehydrated, concentrated and purified to prepare a silica sol with a concentration of 20 wt%, wherein the silica particle size was between 1-100nm.

[0053] At room temperature, add 10 g of carboxymethyl cellulose to deionized water, stir until completely dissolved under nitrogen protection, then add 4 g of 20 wt % superfine silica sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com