Super-strength osmosis-resistant high-aluminum brick

A technology of anti-permeation and high-alumina bricks, which is applied in the field of refractory products for high-temperature kilns and super anti-permeation high-alumina bricks. It can solve the problems of refractory material penetration and peeling, reduce the quality of molten aluminum, and low strength, so as to prevent penetration and adhesion. , good corrosion resistance, and the effect of improving the strength of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

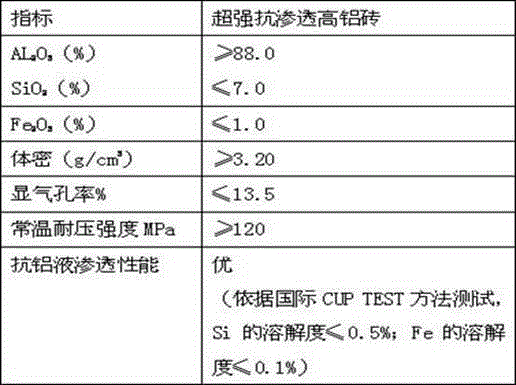

Image

Examples

Embodiment 1

[0031] A super-permeability-resistant high-alumina brick is characterized in that its raw materials are proportioned according to the following parts by weight:

[0032] (1). Fused brown corundum particles: 58 parts, wherein the weight ratio of fused brown corundum with a particle size of 1-0 mm to fused brown corundum with a particle size of 3-1 mm is 1:2;

[0033] (2). Fused brown corundum fine powder 200 mesh: 30 parts;

[0034] (3). Alumina micropowder ≤ 5 microns: 10 parts;

[0035] (4).Super-grade Guangxi white clay 200 mesh: 2 parts;

[0036] 7 parts of 85% concentration solution of binding agent.

[0037] The manufacturing process of the super-strong anti-permeability high-alumina brick is:

[0038] (1) Premixing: Mix the fused brown corundum particles in the above raw materials together according to the stated ratio, and stir evenly;

[0039] (2) Mixing: first mix the pre-mixed granules according to the stated weight ratio, add a special binder 85% concentration s...

Embodiment 2

[0043] A super-permeability-resistant high-alumina brick is characterized in that its raw materials are proportioned according to the following parts by weight:

[0044] (1) Fused brown corundum particles: 50 parts; wherein the weight ratio of fused brown corundum with a particle size of 1-0 mm to fused brown corundum with a particle size of 3-1 mm is 1:2;

[0045] (2) Fused brown corundum fine powder 200 mesh: 35 parts;

[0046] (3) Aluminum oxide powder ≤ 5 microns: 12 parts

[0047] (4) 200 mesh super-grade Guangxi white clay: 3 parts;

[0048] 6 parts of special binder 85% concentration solution.

[0049] The manufacturing process of the super-strong anti-permeation high-alumina brick is the same as that of Example 1, and the firing time is 6 hours.

Embodiment 3

[0051] A super-permeability-resistant high-alumina brick is characterized in that its raw materials are proportioned according to the following parts by weight:

[0052] (1) Fused brown corundum particles: 63 parts; wherein the weight ratio of fused brown corundum with a particle size of 1-0mm to fused brown corundum with a particle size of 3-1mm is 1:2;

[0053] (2) Fused brown corundum fine powder 200 mesh: 25 parts;

[0054] (3) Aluminum oxide powder ≤ 5 microns: 10 parts;

[0055] (4) 200 mesh super-grade Guangxi white clay: 2 parts;

[0056] 8 parts of special binder 85% concentration solution.

[0057] The manufacturing process of the super-strong anti-permeability high-alumina brick is the same as that of Example 1, and the firing time is 5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com