Treatment device of ceftriaxone synthesis pharmaceutical production waste water

A technology for the production of waste water and treatment devices, which is applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of reducing photocatalyst activity and affecting the treatment effect, so as to reduce the load , Low operating cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

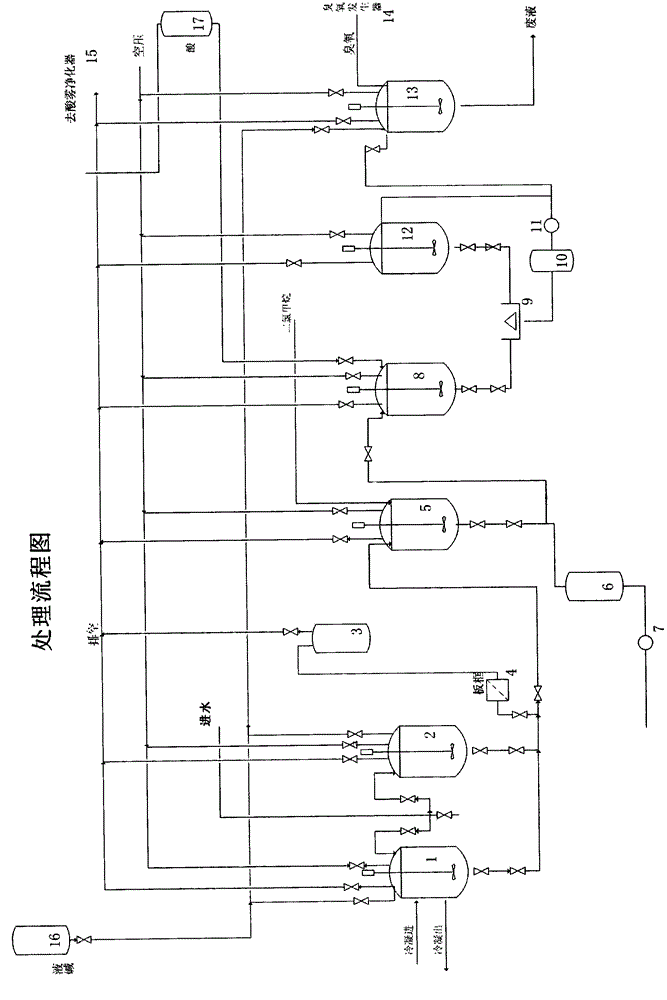

[0035] 1. Pour pine crude product residue (COD greater than 150,000) into reaction tanks 1 and 2, add 30% lye in storage tank 16 into the reaction tank to adjust the pH to 13-13.5, stir for 10-30min, and let stand for 30-60min Post liquid;

[0036] 2. In step 1, the organic phase is triethylamine, which is filtered through the plate frame 4 and enters the storage tank 3 for recovery;

[0037] 3. The water phase in step 1 enters the tank 5, extracts and stirs with 0.3 times dichloromethane for 10-15 minutes, and then stands still for 15-30 minutes to separate the phases;

[0038] 4. In step 3, the organic phase enters storage tank 6 to be distilled;

[0039] 5. Add the 30% hydrochloric acid in the storage tank 17 to the reaction tanks 8 and 12, adjust the pH to 1.9-2.1, stir for 10-30 minutes, and enter the centrifuge 9 for centrifugation to obtain the accelerator M;

[0040] 6. The centrate liquid in step 5 enters the storage tank 10, adds activated carbon at room temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com