Multifunctional efficient decolorizing flocculant and preparation method thereof

A high-efficiency decolorizing flocculant and multi-functional technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water treatment parameter control, etc., can solve unsatisfactory treatment effect, poor COD reduction effect, and affect product appearance and other problems, to achieve the effect of reducing the cost of sewage treatment, fast flocculation speed, and improving the effect of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

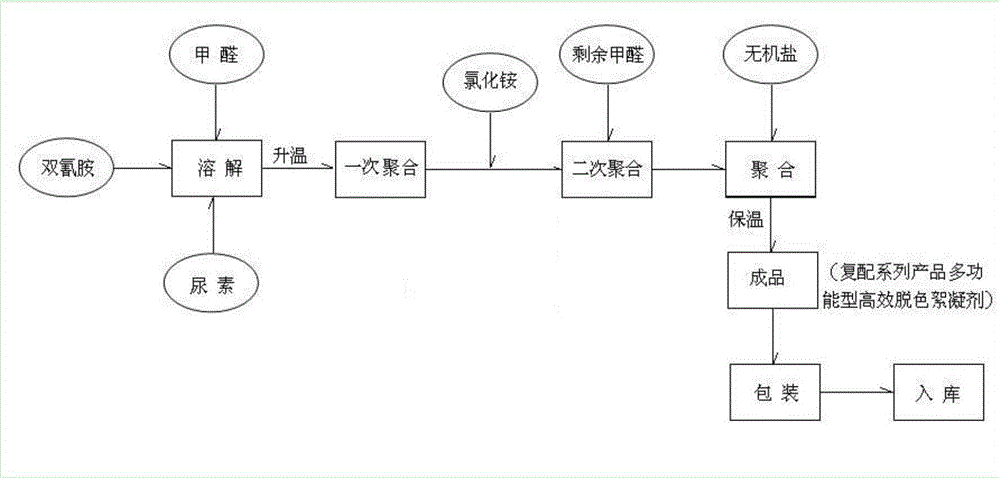

Method used

Image

Examples

Embodiment 1

[0030] Formula: formaldehyde (formaldehyde aqueous solution with a mass concentration of 37%): 15%; dicyandiamide: 12%; ammonium chloride: 28%; urea: 18%; inorganic salts: 27%.

[0031] Preparation method: Put 100 kg of formaldehyde (accounting for 2 / 3 of the total formaldehyde), 120 kg of dicyandiamide, and 180 kg of urea into a stainless steel reaction kettle equipped with a reflux condenser in sequence, stir and heat up to 40°C ± 2°C, stop Heating, adding 280 kg of ammonium chloride, after the exothermic peak of the reaction, add the remaining 50 kg of formaldehyde, control the temperature at 85 degrees ± 2 degrees for condensation reaction, keep warm for 3 hours, then add 90 kg of ferric chloride, polymerized chlorine 180 kg of aluminum, stirring for 30 minutes, made a new type of industrial wastewater treatment agent --- multifunctional high-efficiency decolorizing flocculant.

Embodiment 2

[0033] Formula: formaldehyde (formaldehyde aqueous solution with a mass concentration of 37%): 25%; dicyandiamide: 20%; ammonium chloride: 22%; urea: 13%; inorganic salts: 20%.

[0034] Preparation method: Put 150 kg of formaldehyde (accounting for 3 / 5 of the total formaldehyde), 200 kg of dicyandiamide, and 130 kg of urea into a stainless steel reaction kettle equipped with a reflux condenser in sequence, stir and heat up to 45 degrees ± 2 degrees, stop Heating, adding 220 kg of ammonium chloride, after the exothermic peak of the reaction, add the remaining 100 kg of formaldehyde, control the temperature at 80 °C ± 2 °C for condensation reaction, keep warm for 2 hours, then add 82.5 kg of ferric chloride, polymerized chlorine 105.5 kg of aluminum and 12 kg of silicon dioxide were stirred for 50 minutes to prepare a new type of industrial wastewater treatment agent---a multifunctional high-efficiency decolorizing flocculant.

Embodiment 3

[0036] Formula: formaldehyde (formaldehyde aqueous solution with a mass concentration of 37%): 18%; dicyandiamide: 14%; ammonium chloride: 24%; urea: 14%; inorganic salts: 30%.

[0037] Preparation method: Put 112 kg of formaldehyde (between 3 / 5 and 2 / 3 of the total formaldehyde), 140 kg of dicyandiamide, and 140 kg of urea into a stainless steel reaction kettle equipped with a reflux condenser in sequence, stir and heat up to 50 Temperature ± 2 degrees, stop heating, add 240 kg of ammonium chloride, after the peak of the exothermic reaction, add the remaining formaldehyde 68 kg, control the temperature at 90 degrees ± 2 degrees for condensation reaction, keep warm for 4 hours, and then add trichloride 100 kg of iron, 100 kg of ferrous sulfate, and 100 kg of polyaluminum chloride were stirred for 2 hours to prepare a new type of industrial wastewater treatment agent---a multifunctional high-efficiency decolorizing flocculant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com