Method for recovering and treating coking phenol-cyanogen wastewater by adopting Isa furnace

A technology of recovery treatment and Isa furnace, which is applied in the field of coking phenol cyanide wastewater treatment by Isa furnace, can solve the problems of boiler operators and environmental pollution, difficult treatment of polluted area, incomplete combustion, etc., and is easy to popularize and decompose Thorough, cost-saving results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

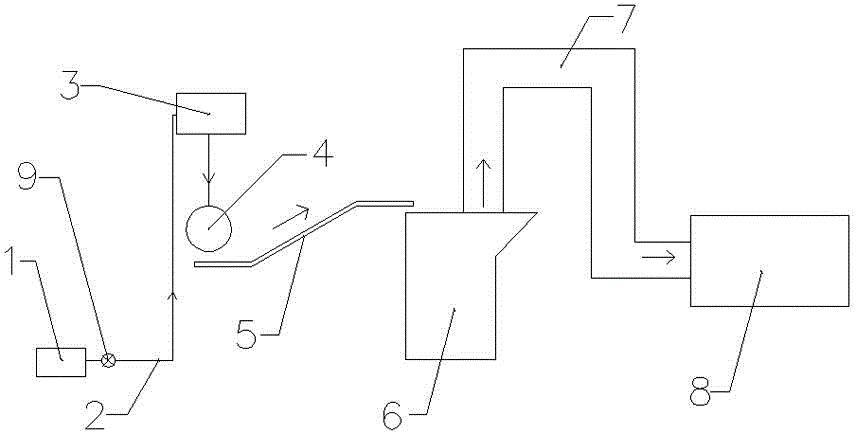

[0058] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0059] a. Pretreatment: Collect the produced phenol cyanide wastewater in the phenol pool for pretreatment;

[0060] When 25-30 tons of phenol cyanide wastewater is produced per month, the phenol cyanide wastewater is collected by a phenol pool with a length of 3m, a width of 1.5m, and a height of 2.5m for pretreatment

[0061] b. Granulation water replenishment: when the material is granulated, according to the original water content ratio of the material, the phenol cyanide wastewater is used to replenish the water of the material;

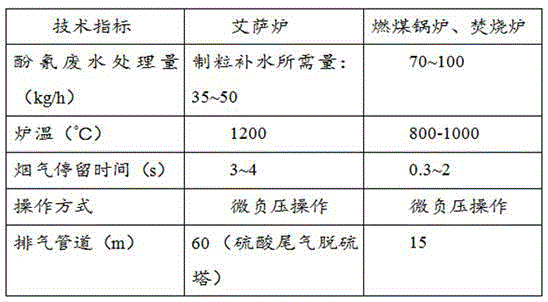

[0062] c. Melting: The phenol cyanide wastewater is attached to the material particles, enters the Isa furnace from bottom to top with the feeding system, passes through the high temperature of the melting pool greater than or equal to 1200 degrees Celsius, and the phenol cyanide was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com