Automatic scriber and method of application thereof

An automatic scribing and scribing technology, applied in workshop equipment, manufacturing tools, etc., can solve the problems of inconsistent scribing depth, high manual scribing work intensity, and inability to maintain constant scribing, etc., so as to improve the scribing efficiency. , the effect of reducing the scribing intensity, reducing the intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

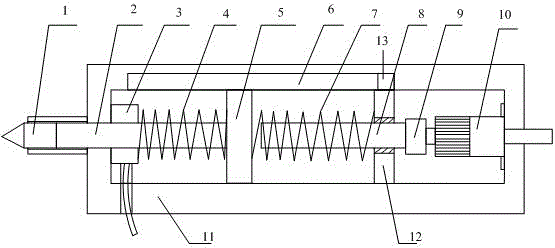

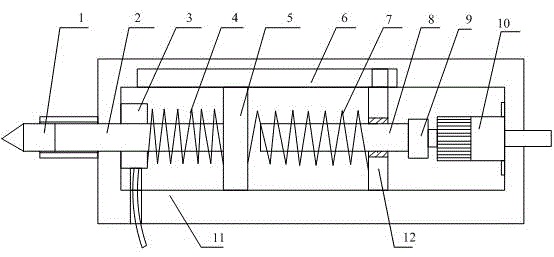

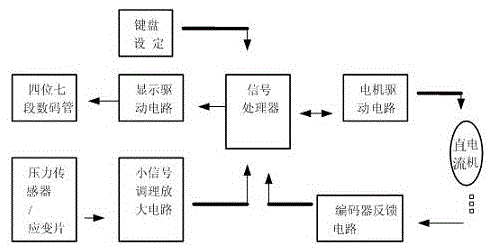

[0030] The automatic scriber includes a hollow stylus cylinder 11, a pressure detection device 3 is installed on the inner wall of the left end of the stylus cylinder 11, a DC motor 10 is installed on the inner wall of the right end of the stylus cylinder 11, and a scribing needle 1 is installed on the left end. The needle linkage shaft 2, the right end of the needle linkage shaft 2 is inserted into the needle cylinder 11 from the outer wall of the left end of the needle cylinder 11, the needle linkage shaft 2 runs through the pressure detection device 3 at the same time, and the needle linkage shaft 2 extends to the needle cylinder One end inside 11 is connected with a slide block 5, and a first pre-tightened coil spring 4 sleeved on the needle linkage shaft 2 is set between the slide block and the pressure detection device 3, and one end of the first pre-tightened coil spring is connected to the pressure detection device 3. The device 3 is connected, and the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com