Bolt type twisting handle

A plug-type and plug-in technology, which is applied to turning equipment, parts of boring machine/drilling machine, accessories of toolholders, etc., can solve the problems of reducing the mechanical strength of microscopic fiber structures and affecting the cutting efficiency of crown drills, etc., to improve drilling performance , smooth chip discharge and optimized flute shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

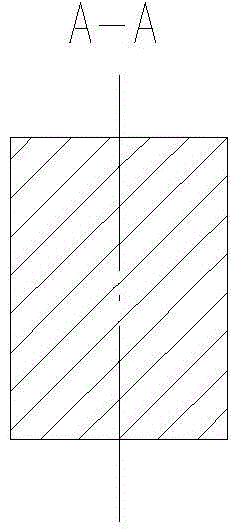

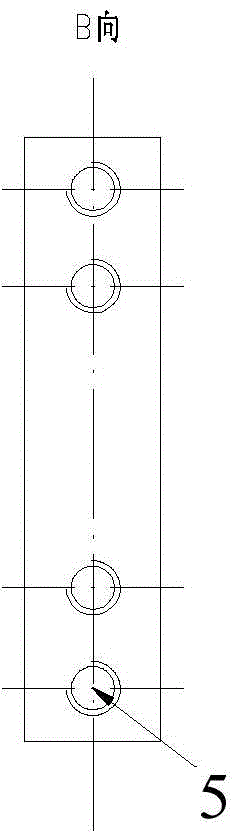

[0024] Such as figure 1 As shown, the bolt-type twist handle includes a handle body 1, a bolt 3 and a fastening screw 4. The handle body 1 has a T-shaped structure, including a head on the left and a tail on the right, as shown in figure 2 , the tail is a square prism structure, which can be placed on the square tool holder of the lathe like a turning tool; the head is provided with a round hole 2 for installing the drill body along the front and rear directions, so that the drill body can be inserted into the round hole when working 2. The head is provided with a pin hole 6 for installing the latch 3 along the up and down direction, such as Figure 4 , the pin hole intersects with the round hole, and the left side of the head is provided with threaded holes 5 for installing fastening screws 4 from left to right, such as image 3 , the threaded hole intersects with the pin hole for fastening the bolt 3.

[0025] Wherein, there are two pin holes 6, one upper and lower respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com