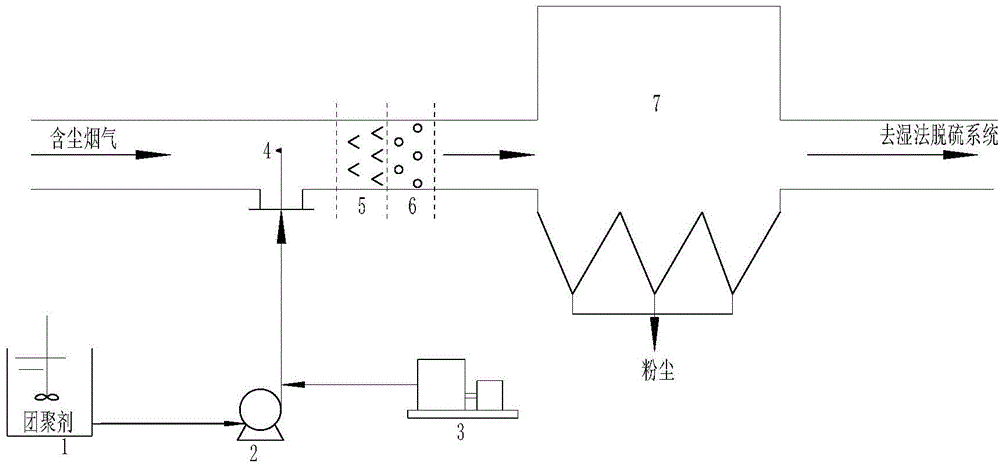

Device and method for increasing grain size of PM2.5 (particulate matter2.5) through turbulent flow and chemical agglomeration coupling

A technology of chemical agglomeration and turbulent flow, which is applied in the direction of chemical instruments and methods, solid separation, electrostatic effect separation, etc. It can solve the problems of difficult removal, limited growth effect of fine particle agglomeration, insufficient charging, etc., and prolong the residence time , enhance the growth effect, improve the effect of removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dust-containing flue gas is produced by a fully automatic coal-fired boiler, with a flue gas volume of 300Nm 3 / h, at the same time, use the aerosol generator to add fly ash to ensure that the concentration of fine particles in the dust-containing flue gas at the inlet of the device is 3g / Nm 3 . The dust-laden flue gas flows through the chemical agglomeration zone and the turbulence zone in the flue sequentially, and finally enters the electrostatic precipitator. PM in flue gas when flowing through chemical agglomeration zone 2.5 The particles are in preliminary contact with the agglomerating agent droplets sprayed through the two-fluid atomizing nozzle, the agglomerating agent droplets evaporate, and PM during the evaporation process 2.5 Linked by polymer chains with polar groups to promote PM 2.5 The particle size increases. Then it flows through the turbulent zone, and the turbulence generated by the spoiler promotes the agglomeration droplets and PM 2.5 And PM 2.5 Col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com