Preparation method and application of micro-fine particle coal flotation reagent

A technology for flotation reagents and fine particles, applied in flotation, solid separation, etc., can solve the problems of high cost of reagents, unsatisfactory flotation effect, large dosage, etc., and achieve improved flotation efficiency, low production cost, and high harvest The effect of performance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

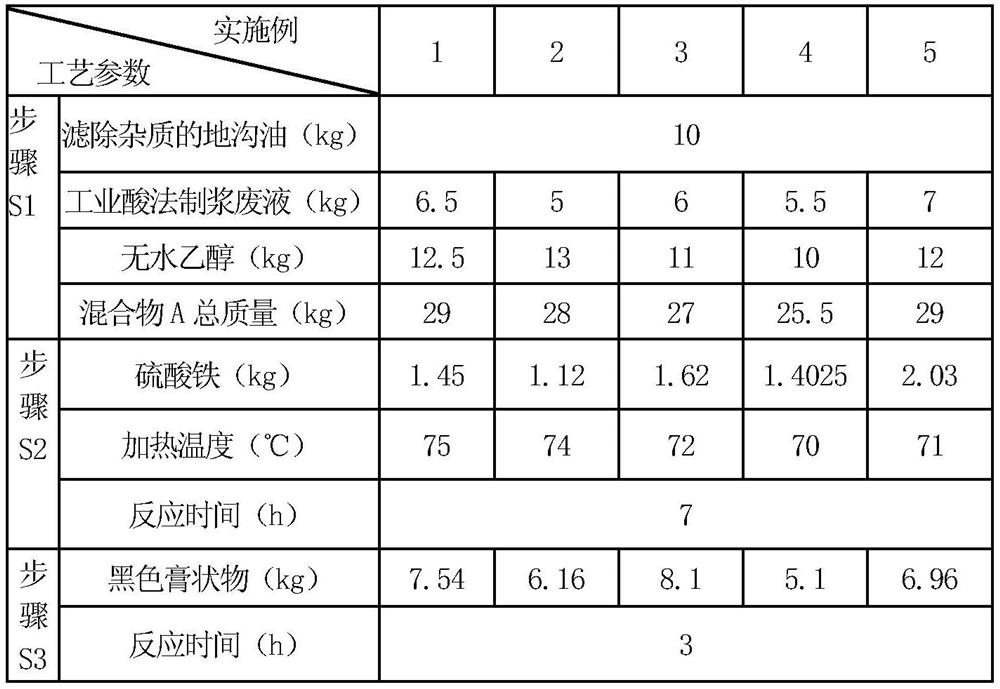

[0022] The preparation method of embodiment 1-5 fine coal flotation agent

[0023] A kind of preparation method of fine-grained coal flotation agent, the process parameter in the preparation method is as shown in table 1, and preparation method comprises the following steps:

[0024] S1. Take the gutter oil with a mass ratio of 1:0.5-0.7:1-1.3 to filter out impurities, industrial acid pulping waste liquid and absolute ethanol, and mix them to obtain a mixture A;

[0025] S2. Add ferric sulfate to the mixture A, the mass of the added ferric sulfate is 4%-7% of the total mass of the mixture A, heat to 70-75° C., react for 7 hours, and obtain the mixture B;

[0026] S3, adding the black paste produced in the process of producing vitamin B6 by the oxazole method to the mixture B, the quality of the black paste produced in the process of producing vitamin B6 by the added oxazole method is 20%-30% of the total mass of the mixture A %, react for 3 hours, cool, emulsify, and form a m...

Embodiment 6-8

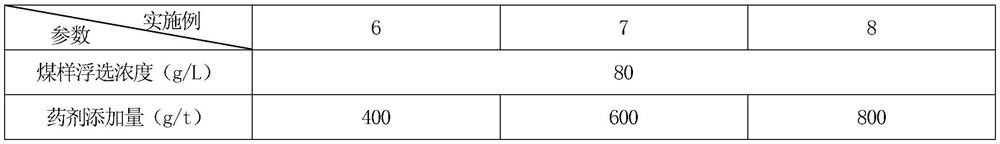

[0030] Example 6-8 Application of Fine Coal Flotation Agents

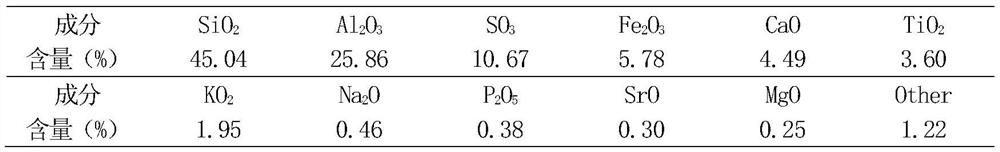

[0031] Implement the microfine coal flotation agent that 1-5 makes is applied to the sorting of fine coal, embodiment 6-9 adopts the microfine coal flotation agent that embodiment 1 makes to carry out the separation of fine coal, coal sample The ash content of the floating coal sample was 17.2%, and the -0.045mm particle size content in the coal sample was 37.85%, which was the dominant particle size of the coal sample. The gangue minerals are mainly quartz, mica and kaolin, etc., and the mass percentages of their main chemical components are shown in Table 2.

[0032] Table 2 The main chemical components of the floating coal samples

[0033]

[0034] The fine-grained coal flotation test uses a 1.0L XFD type hanging cell flotation machine, and the spindle speed is 1800r / min. Weigh three parts of 80g coal samples and pour them into the flotation tank respectively and add tap water. The three groups of flotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com