A raw material pretreatment method for kimchi processing

A pretreatment and raw material technology, applied in the functions of food ingredients, food drying, food science, etc., can solve the problems of losing the flavor characteristics of traditional kimchi, curbing the industrialization of kimchi, and unfavorable health, so as to reduce the quality of raw materials and nutritional loss, Eliminate the production of organic pollutants such as COD and BOD and high-salt wastewater, and achieve high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

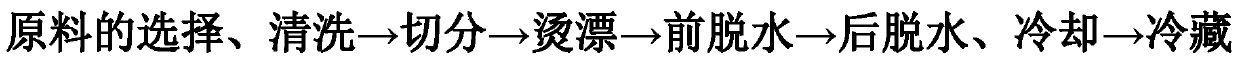

[0030] A raw material pretreatment method for kimchi processing, comprising the following steps:

[0031] A. Selection and cleaning of raw materials: select fresh and intact white radish, and clean the white radish with a spray drum cleaning machine;

[0032] B. Cutting: Use a vegetable cutter to cut the white radish into 1cm squares and 8cm long strips;

[0033] C. Blanching: Dip the sliced white radish strips into the pre-prepared compound blanching liquid (the volume ratio of the color protection liquid to the crispness protection liquid is V 护色液 :V 护脆液 =1:1, where the color protecting solution is a mixed aqueous solution containing 1.5% citric acid and 1.0% salt by mass fraction, and the embrittlement protecting solution is a calcium lactate aqueous solution with a concentration of 20g / L), at a temperature of 70°C Blanch for 60 seconds, take it out, soak in cold water immediately and drain;

[0034] D. Pre-dehydration: Adjust the radiation distance of the short-wave i...

Embodiment 2

[0038] A raw material pretreatment method for kimchi processing, comprising the following steps:

[0039] A. Selection and cleaning of raw materials: select fresh and intact lettuce, and clean the lettuce with a spray drum cleaning machine;

[0040] B. Cutting: Cut the lettuce into lettuce slices with a thickness of about 1cm with a vegetable cutter;

[0041] C. Blanching: Dip the sliced lettuce slices into the pre-prepared composite blanching solution (the volume ratio of the color protection solution to the crispness protection solution is V 护色液 :V 护脆液 =1:1, where the color protecting solution is a mixed aqueous solution containing 1.5% citric acid and 1.0% salt by mass fraction, and the embrittlement protecting solution is a calcium lactate aqueous solution with a concentration of 20g / L), at a temperature of 70°C Blanch for 60 seconds, take it out, soak in cold water immediately and drain;

[0042] D. Pre-dehydration: Adjust the radiation distance of the short-wave inf...

Embodiment 3

[0046] A raw material pretreatment method for kimchi processing, comprising the following steps:

[0047] A. Selection and cleaning of raw materials: select fresh and intact scallions, and clean the scallions with a spray drum cleaning machine;

[0048] B. Blanching: immerse the onion head into the compound blanching liquid prepared in advance (the volume ratio of the color protection liquid to the crisp protection liquid V 护色液 :V 护脆液 =1:1, where the color protecting solution is a mixed aqueous solution containing 1.5% citric acid and 1.0% salt by mass fraction, and the embrittlement protecting solution is a calcium lactate aqueous solution with a concentration of 20g / L), at a temperature of 70°C Blanch for 60 seconds, take it out, soak in cold water immediately and drain;

[0049] C. Pre-dehydration: Adjust the radiation distance of the medium and short wave infrared drying oven to 10cm, the power to 900W, and the temperature of the drying oven to 70°C. After the drying ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com