Collector, electrode, secondary cell, and capacitor

A current collector and electrode technology, applied in the field of current collectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

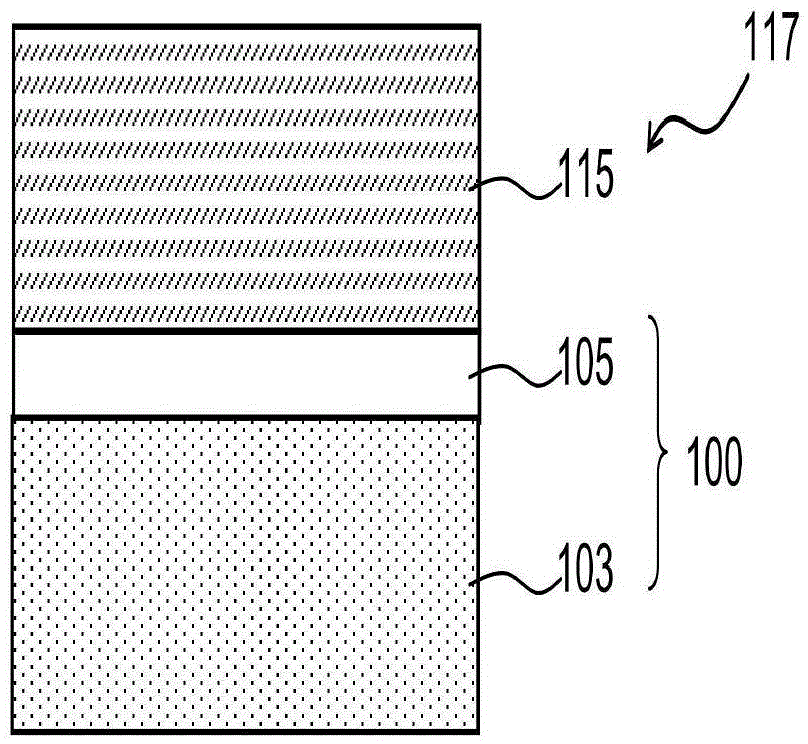

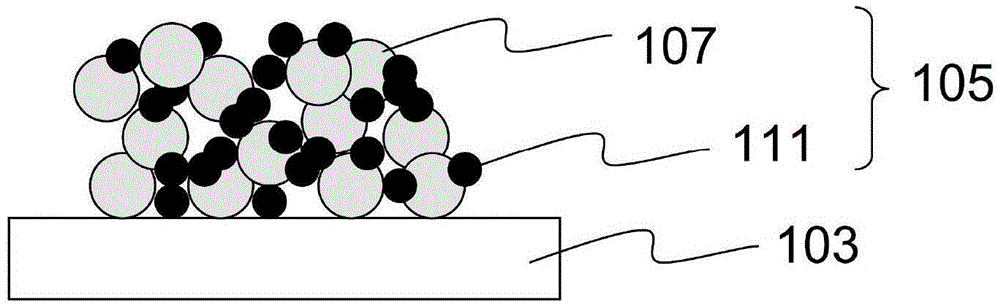

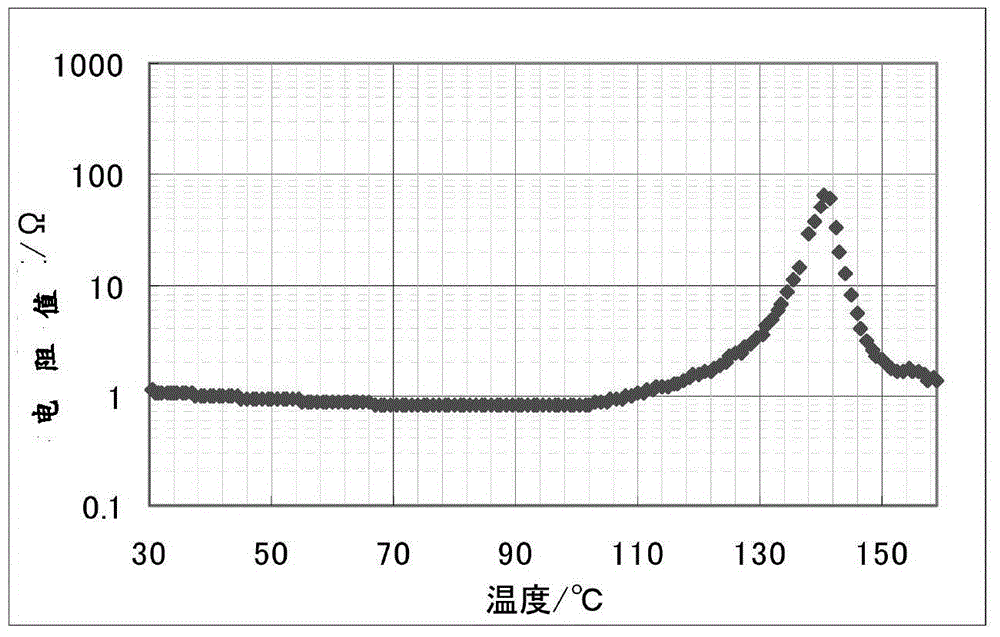

[0108] Resin A (acid-modified polypropylene latex, melting point 138.6 ° C, solid content 29.5%, number average particle diameter 0.3 μm, weight average molecular weight 80000), acetylene black (hereinafter referred to as AB) and silica (colloidal silica , particle size 450nm, solid content 40%) after mixing, the coating liquid was stirred with a disperser (Disperse) (resin A: AB: silica=85:10:5 (volume ratio), solvent is water). The prepared coating solution was applied to an A1085 foil (thickness 15 μm) so that the thickness of the coating film was 2 μm, and dried at 100° C. and 140° C. for 1 minute respectively to obtain a CC foil having a film thickness of 2.2 μm. In addition, the latex of the above-mentioned resin A had good coatability with respect to the A1085 foil (the phenomenon of coating unevenness was found to be few when observed with the naked eye).

Embodiment 2

[0110] After mixing resin A, AB and silicon dioxide (colloidal silicon dioxide, particle size 450nm, solid content 40%), stir the coating solution with a disperser (resin A:AB:silica=80:10:10( volume ratio), the solvent is water). The prepared coating solution was applied to an A1085 foil (thickness 15 μm) so that the thickness of the coating film was 2 μm, and dried at 100° C. and 140° C. for 1 minute respectively to obtain a CC foil having a film thickness of 2.2 μm. In addition, the latex of the above-mentioned resin A had good coatability with respect to the A1085 foil (the phenomenon of coating unevenness was found to be few when observed with the naked eye).

Embodiment 3

[0112] After mixing resin A, AB and alumina (fine particles of alumina, particle size 700nm), stir the coating solution with a disperser (resin A:AB:alumina=80:10:10 (volume ratio), solvent is water) . The prepared coating solution was applied to an A1085 foil (thickness 15 μm) so that the thickness of the coating film was 2 μm, and dried at 100° C. and 140° C. for 1 minute respectively to obtain a CC foil having a film thickness of 2.2 μm. In addition, the latex of the above-mentioned resin A had good coatability with respect to the A1085 foil (the phenomenon of coating unevenness was found to be few when observed with the naked eye).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com