System and method for diagnosing faults of photovoltaic power generation systems in online manner

A photovoltaic power generation system and fault diagnosis system technology, applied in the field of solar power generation, can solve problems such as low maintenance efficiency, difficulty in reporting monitoring data, false alarms, etc., to achieve accurate monitoring and collection data, simple and reliable step-by-step reporting, and fault monitoring and positioning fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

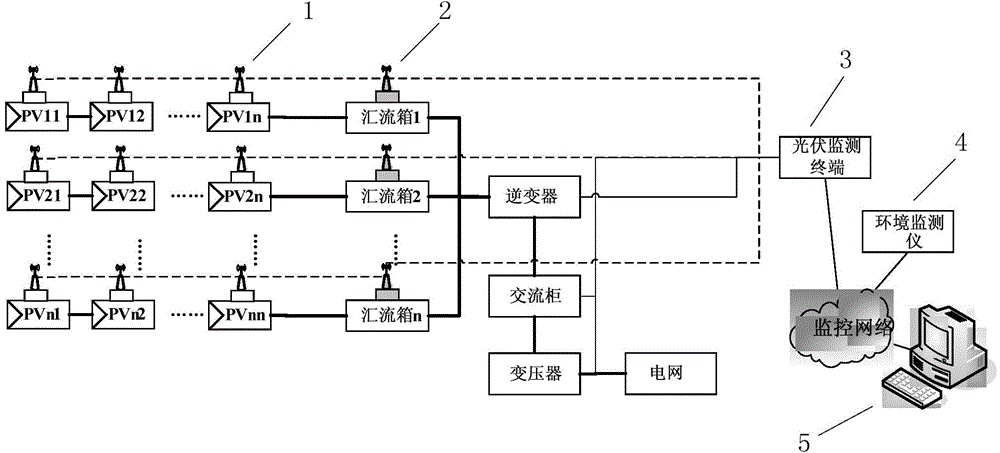

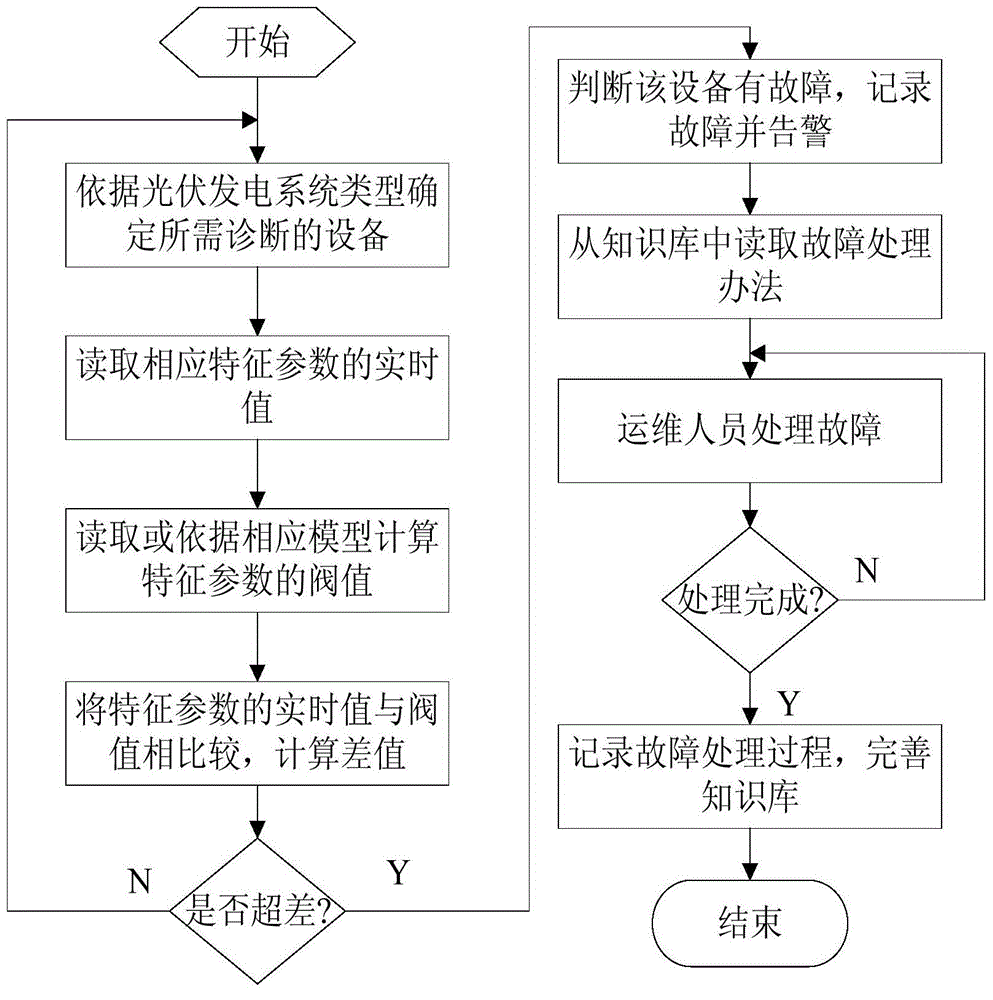

[0032] figure 1 It is a schematic diagram of a medium and high voltage grid-connected non-energy storage photovoltaic power generation system and its monitoring system. The photovoltaic system includes step-up transformers, AC power distribution cabinets, photovoltaic inverters and other equipment. Each photovoltaic inverter is connected to several combiner boxes, and each combiner box is connected to several photovoltaic strings. The string is composed of multiple photovoltaic modules in series; the specific number of the above-mentioned devices depends on the scale of the system. The configuration scheme of its online fault diagnosis system is: a host computer 5, a photovoltaic monitoring terminal 3, an environmental monitor 4, several combiner box monitoring modules 2, and several component monitoring modules 1. When performing online fault diagnosis on a photovoltaic power generation system, the data acquisition and communication process is as follows: first, a component ...

Embodiment 2

[0053] image 3 It is a schematic diagram of a low-voltage grid-connected non-energy storage photovoltaic power generation system and its monitoring system. Compared with Example 1, the structure of the photovoltaic power generation system is almost identical, except that there is no step-up transformer. Therefore, the online fault diagnosis system for the photovoltaic power generation system is the same as that of Embodiment 1, and when performing online fault diagnosis for the photovoltaic power generation system, only the step-up transformer needs to be excluded when determining the equipment to be diagnosed.

[0054] Other technical features are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0056] Figure 4 It is a schematic diagram of a low-voltage grid-connected energy storage photovoltaic power generation system and its monitoring system. Compared with Embodiment 2, the photovoltaic power generation system adds a charge and discharge controller and a storage battery. Its online fault diagnosis method is as follows: the charging and discharging controller collects and monitors the voltage, current, power of its AC and DC terminals and the working temperature of the storage battery, stores and uploads these data to the host computer 5; establishes fault diagnosis of these devices in the host computer 5 Model, determine the characteristic parameters that can characterize the normal operation of these devices, judge whether these operating parameters are in the normal range, and then judge whether the device is faulty.

[0057] For other technical features, refer to Embodiments 1 and 2, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com