Rotary switch

A technology of a rotary switch and an external rotary shaft, which is applied in the field of rotary switches, can solve the problems such as the removal of the abutment member 4 of the turntable and then embedding into another groove, the insufficient number of switching segments, and the inability to make precise electrical contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In order to describe the rotary switch provided by the embodiment of the present invention more clearly, the preferred embodiments of the present invention will be described in detail below with reference to the drawings.

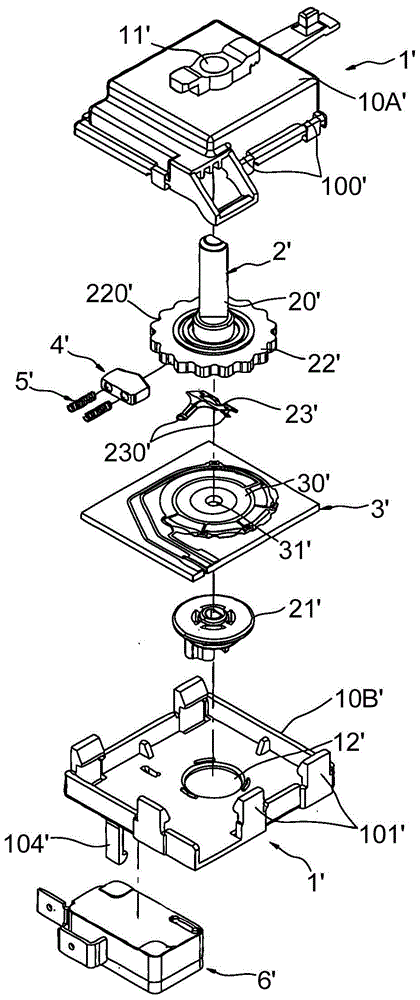

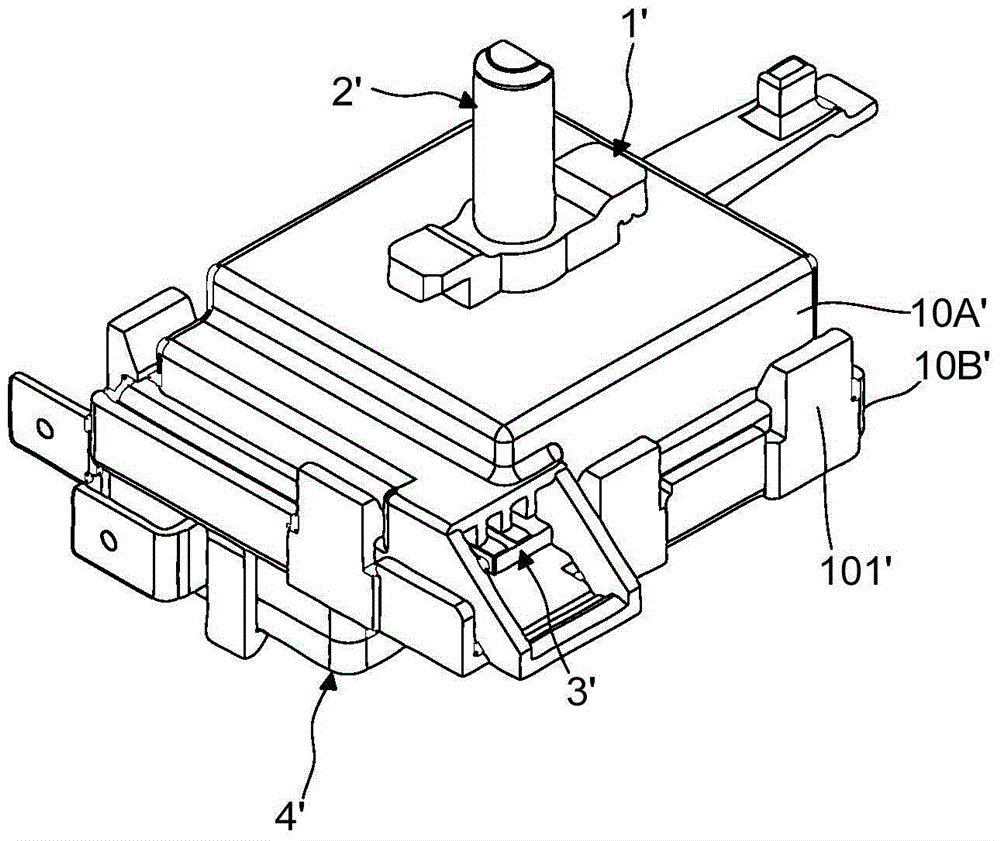

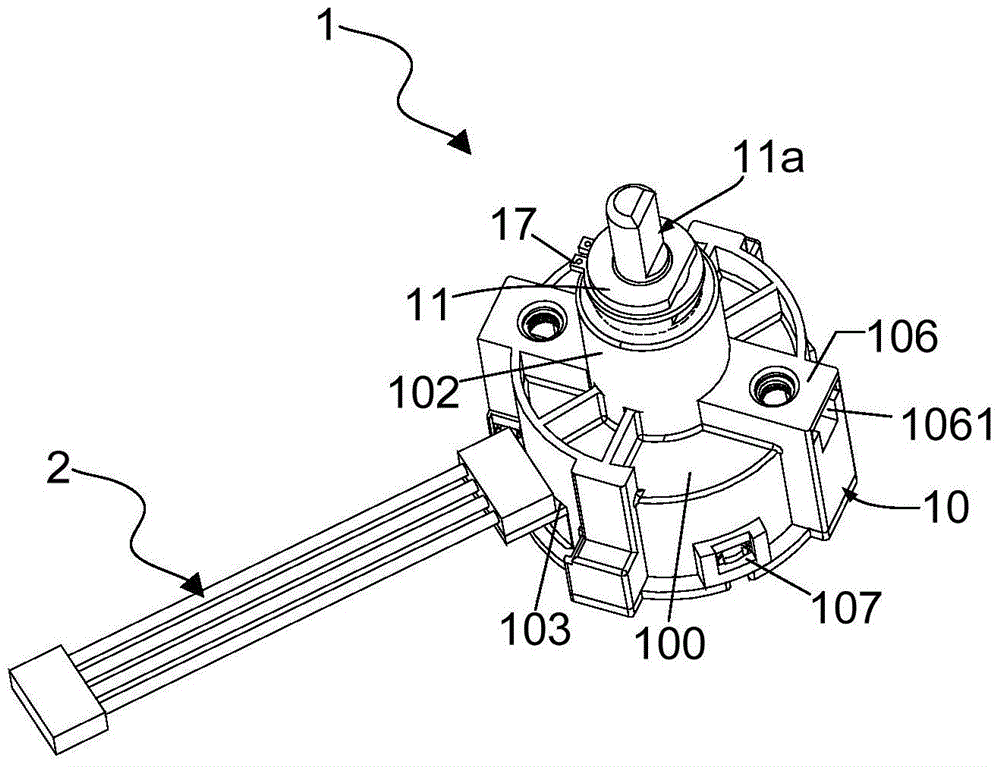

[0073] see image 3 and Figure 4 , image 3 and Figure 4 shows a perspective view of a rotary switch provided by an embodiment of the present invention; and, please also refer to Figure 5 and Image 6 , Figure 5 and Image 6 An exploded view of the rotary switch provided by the embodiment of the present invention is shown. As shown in the figure, the rotary switch 1 provided by the embodiment of the present invention includes: a main cover body 10, a bottom cover plate 16, a hollow outer rotating shaft 11, a first turntable 12, a first propping member 13, a first metal dome 14, The inner rotating shaft 11a, the second turntable 12a, the second abutment piece 13a, the second metal dome 14a, and the double-sided circuit board 15. Wherein, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com