Quantitative measuring method of lithium ion battery electrolyte solvent

A lithium-ion battery, quantitative measurement technology, applied in measurement devices, material separation, instruments, etc., can solve the problems of easy detection by impurities, low quantitative detection accuracy, and high detection equipment requirements, and achieve low detection equipment requirements. Fast, less time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific embodiment one: the quantitative measurement of lithium-ion battery electrolyte solvent and functional additive in this embodiment is carried out according to the following steps:

[0023] 1. Prepare standard solutions of different concentrations with pure substances, and then add internal standard substances of the same quality to make internal standard standard solutions with the same concentration of internal standard substances;

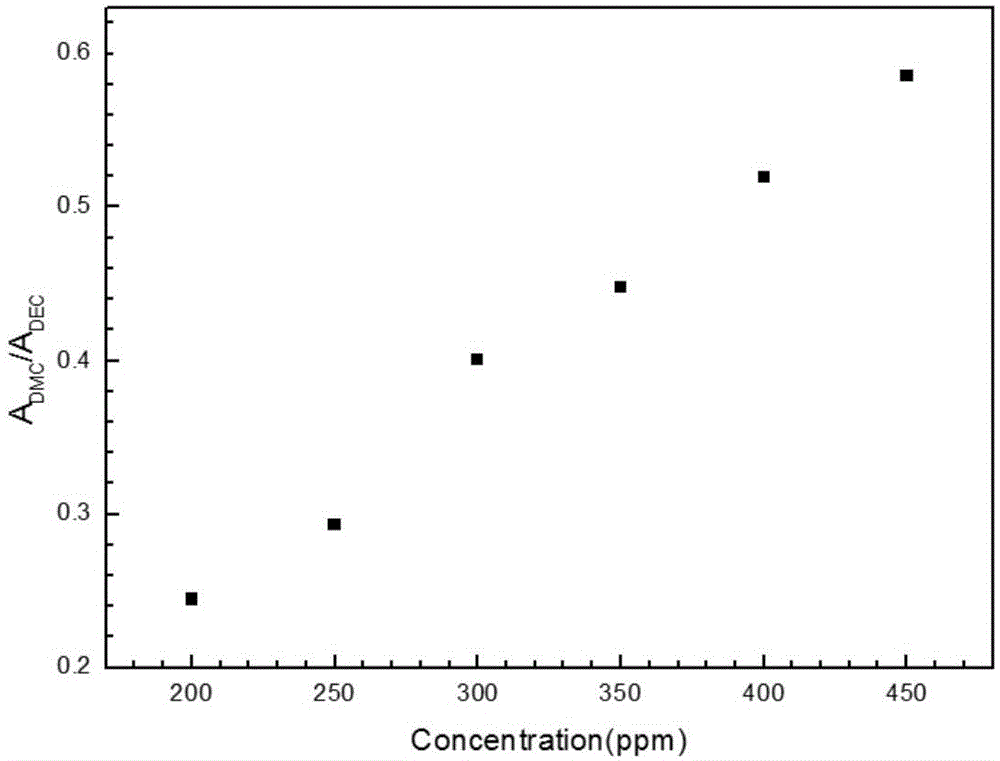

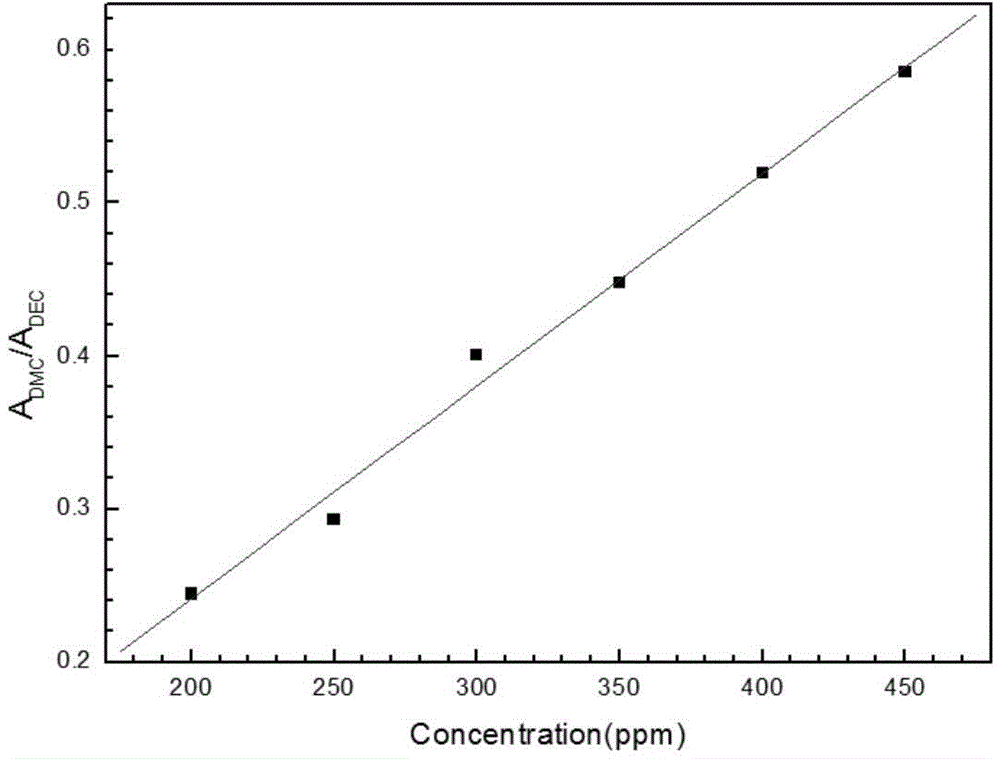

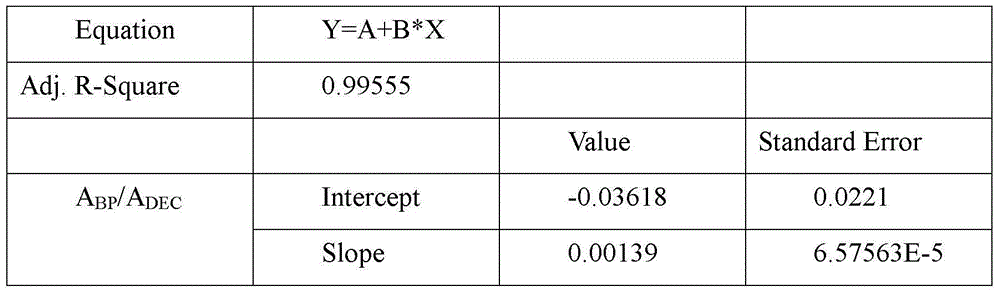

[0024] Two, under the same chromatographic conditions, measure the internal standard standard solution respectively, take the ratio of the chromatographic peak area of the pure substance and the internal standard substance as the ordinate Y, and take the standard solution concentration as the abscissa, draw the internal standard standard working curve of the pure substance ;

[0025] 3. Take a certain quality of the lithium-ion battery electrolyte solvent to be tested, put it into the same solvent as the internal standard soluti...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the solvent used to prepare the internal standard solution in step 1 is acetone, acetonitrile, isopropanol, ethanol or dichloromethane. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step one, the internal standard substance is a component that does not exist in the lithium-ion battery electrolyte solvent to be detected, and the chromatographic peak of the internal standard substance is easily compared with the component to be detected. There is no overlap between the detected substances, and there is no chemical reaction with the detected components, and it can be completely dissolved in the internal standard solution solvent. Other steps and parameters are the same as those in Embodiment 1 or 2.

[0030] The internal standard must meet the following requirements: a. The lithium-ion battery electrolyte solvent sample to be tested does not contain components, can be completely dissolved in the sample, and does not chemically interact with the components to be tested; b. The peak position should be as close as possible to The peak position of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com