Surface-enhanced Raman spectroscopy substrate and preparation method thereof

A surface-enhanced Raman and substrate technology, applied in the field of spectral analysis, to achieve the effects of expanding the use and industrialization prospects, increasing the electric field intensity, and enhancing the electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (Example 1, Surface Enhanced Raman Scattering Substrate)

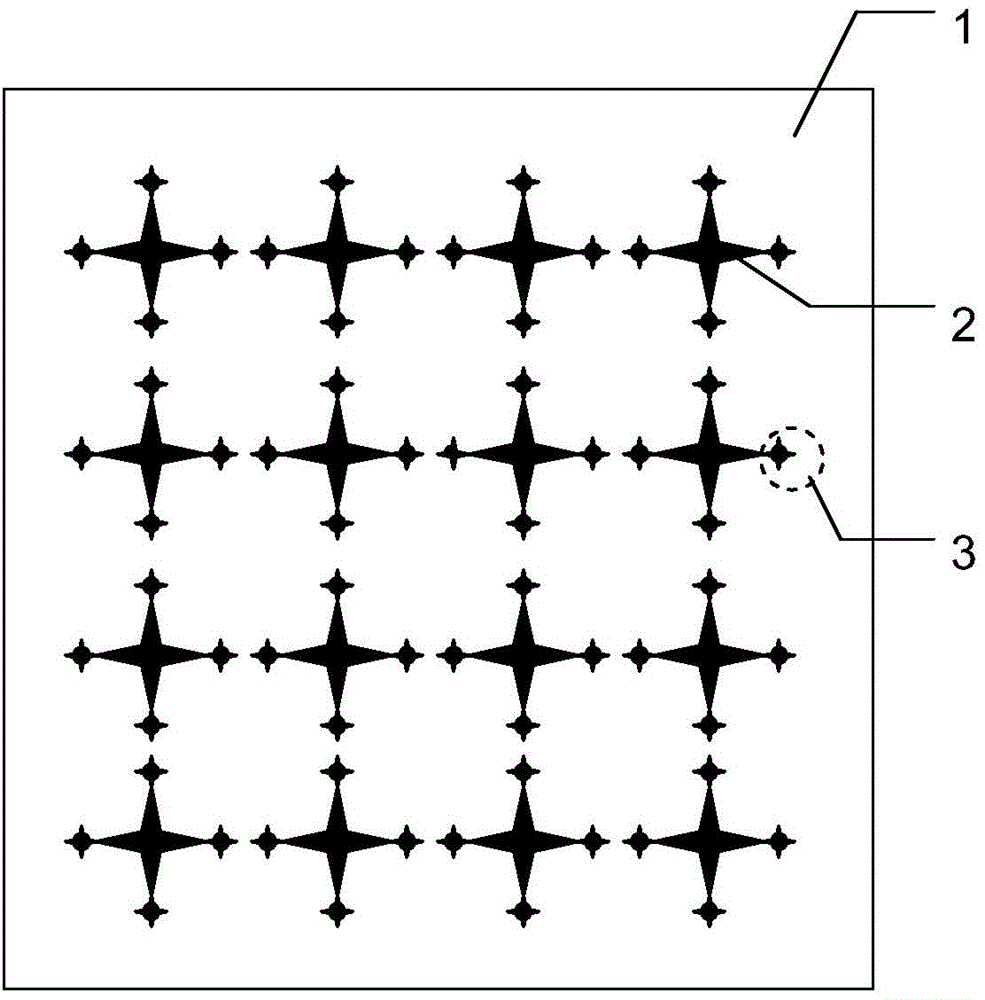

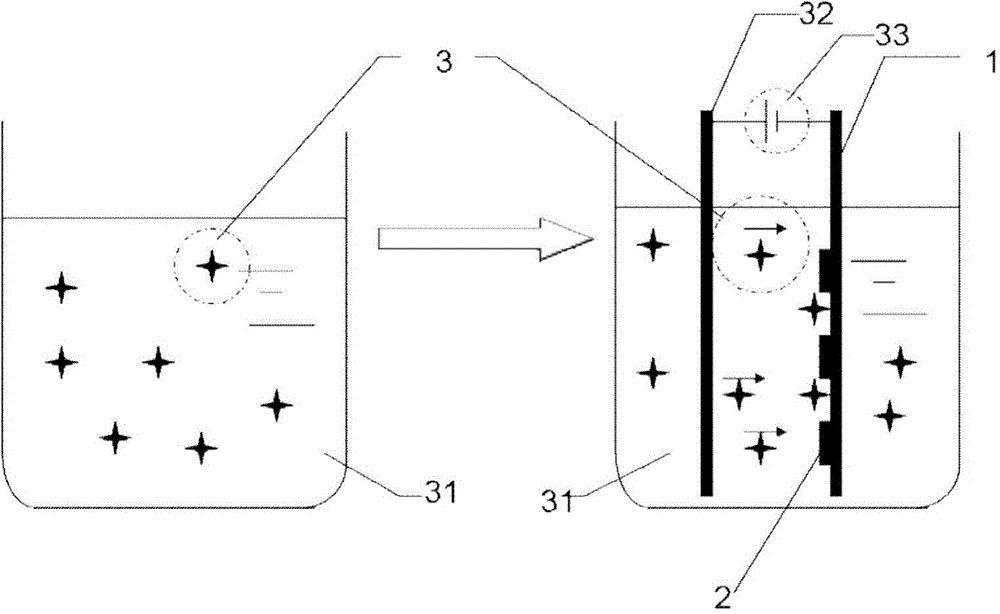

[0041] See figure 1 , the surface-enhanced Raman scattering substrate of this embodiment includes a conductive substrate 1, a two-dimensional noble metal micro-nanostructure array 2 and gold nanostars 3, and the two-dimensional noble metal micro-nanostructure array 2 and gold nanostars 3 are located on the conductive substrate 1 on one side surface.

[0042] The conductive substrate 1 is conductive glass or silicon wafer.

[0043] The two-dimensional noble metal micro-nano structure array 2 is composed of array units aligned vertically and laterally. Each array unit is a star-shaped noble metal thin film, and the noble metal thin film is a gold thin film, a silver thin film or a platinum thin film. The size of each star-shaped noble metal thin film unit is 150nm-1000nm, and the distance between two adjacent units is 10nm-500nm. The array unit is three-pointed star, four-pointed star, five-pointed star, six-po...

Embodiment 2

[0045] (Example 2, preparation method of surface-enhanced Raman scattering substrate)

[0046] In this example, the surface-enhanced Raman scattering substrate described in Example 1 is prepared, and the preparation method includes the following steps:

[0047] ① A photoresist layer containing a two-dimensional star-shaped micro-nano structure array pattern is prepared on the conductive substrate 1 .

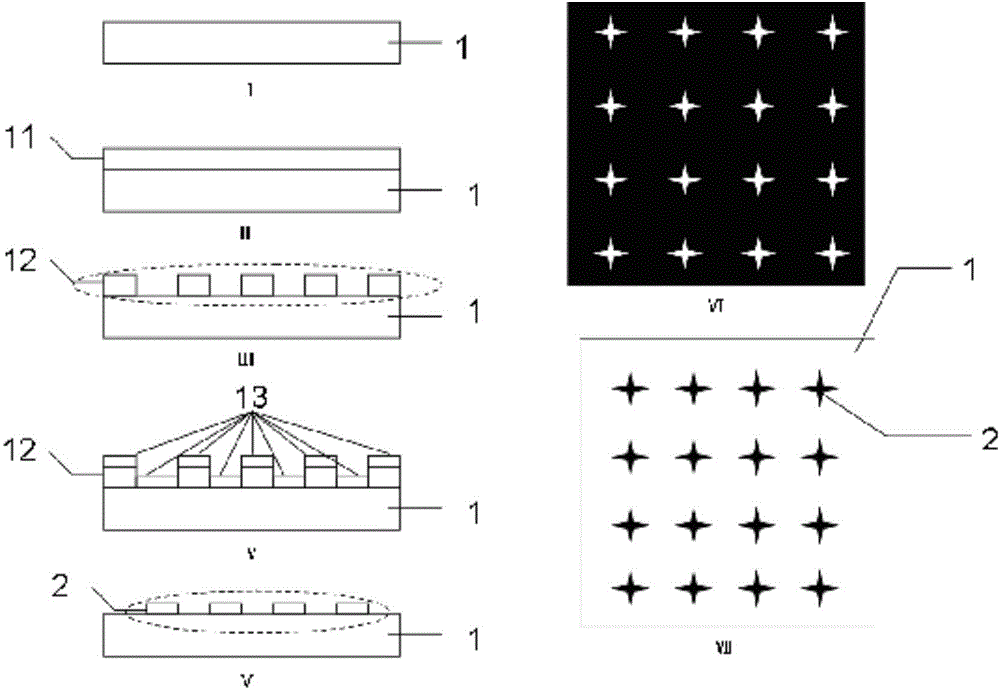

[0048] See figure 2 I. First, the conductive substrate 1 is cleaned to remove particles and impurity ions on the surface. When cleaning, use detergent, acetone, and isopropanol to clean in sequence, and dry them after cleaning.

[0049] See figure 2 II. Spin-coat a layer of positive photoresist 11 on the dried conductive substrate 1, and the thickness of the photoresist 11 is 200nm-500nm.

[0050] See figure 2 III. Soft-baking the photoresist 11 with a hot plate, the temperature of the hot plate is 85°C-120°C, and the soft-baking time is 30s-60s. After the soft baking i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com