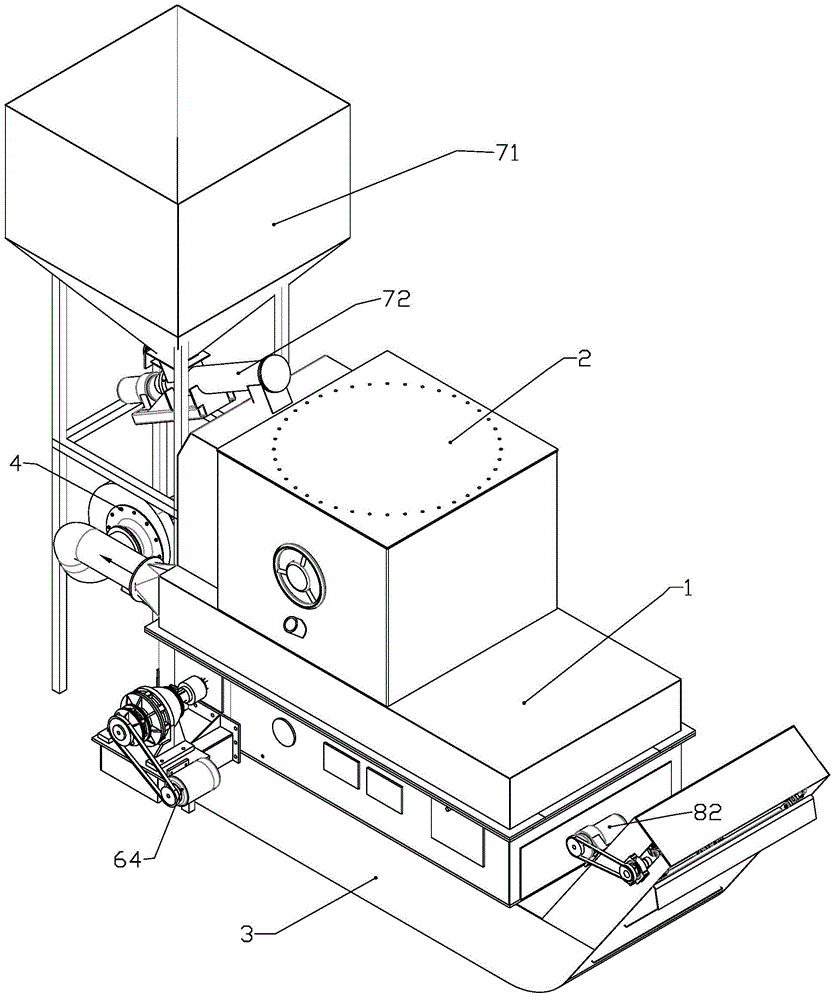

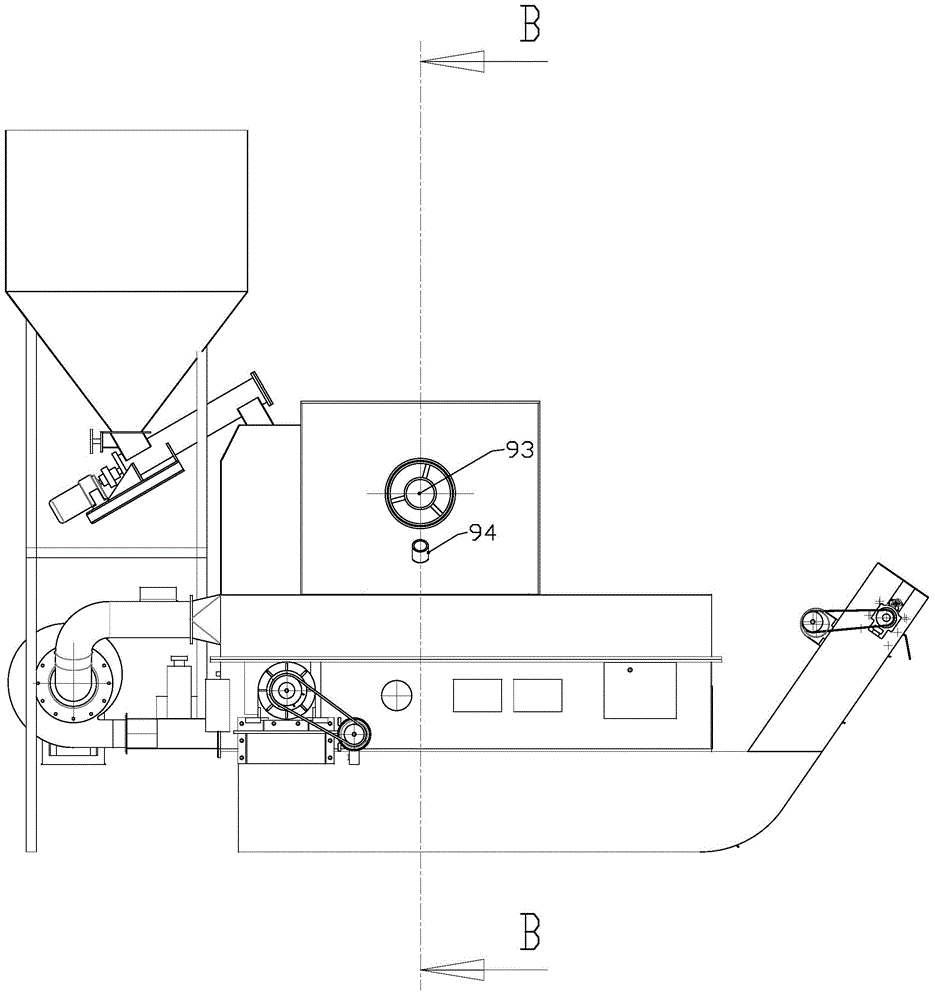

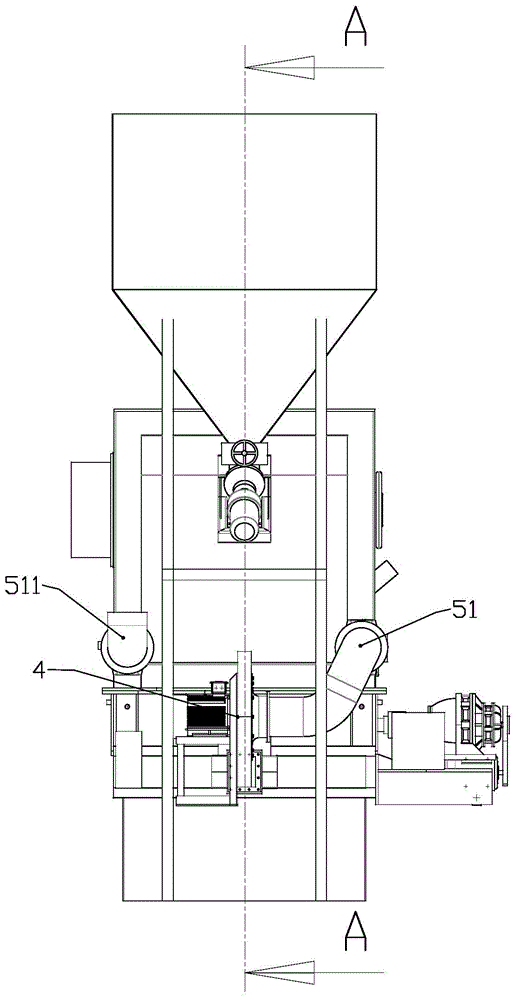

Biomass particle burner and use method thereof

A technology of biomass pellets and burners, which is applied in the direction of combustion methods, combustion equipment, and solid fuel combustion. Emissions, reduction of greenhouse effect, good effect of overall optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Compared with traditional coal and other fuels, biomass pellet fuel has the following characteristics:

[0053] 1. The calorific value is large, the calorific value is about 3900-4800 kcal / kg, and the calorific value after carbonization is as high as 7000-8000 kcal / kg.

[0054] 2. Biomass pellet fuel has high purity and does not contain other sundries that do not generate heat. Its carbon content is 75-85%, ash content is 3-6%, water content is 1-3%, and absolutely does not contain coal gangue, stones, etc. Impurities that do not generate heat but consume heat will directly reduce costs for enterprises.

[0055] 3. Biomass pellet fuel does not contain sulfur and phosphorus, does not corrode the boiler, can prolong the service life of the boiler, and the enterprise will benefit a lot.

[0056] 4. Since biomass pellet fuel does not contain sulfur and phosphorus, it does not produce sulfur dioxide and phosphorus pentoxide during combustion, so it will not cause acid rain,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com