Heat transfer frame type LED light

A technology of LED lights and LED light sources, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc. Eliminate other problems to achieve the effect of increased heat transfer area and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

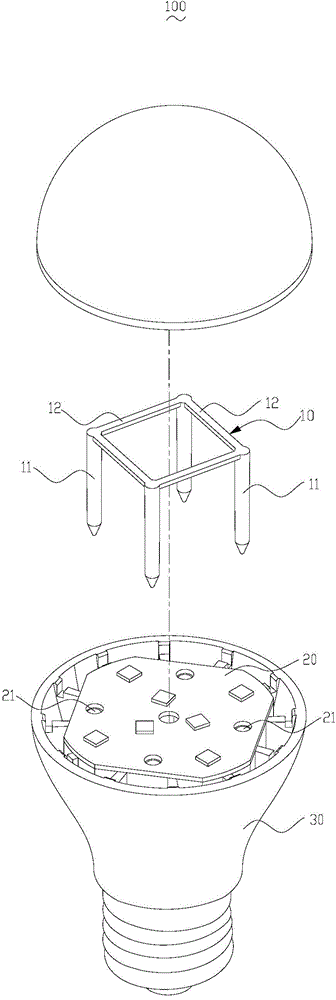

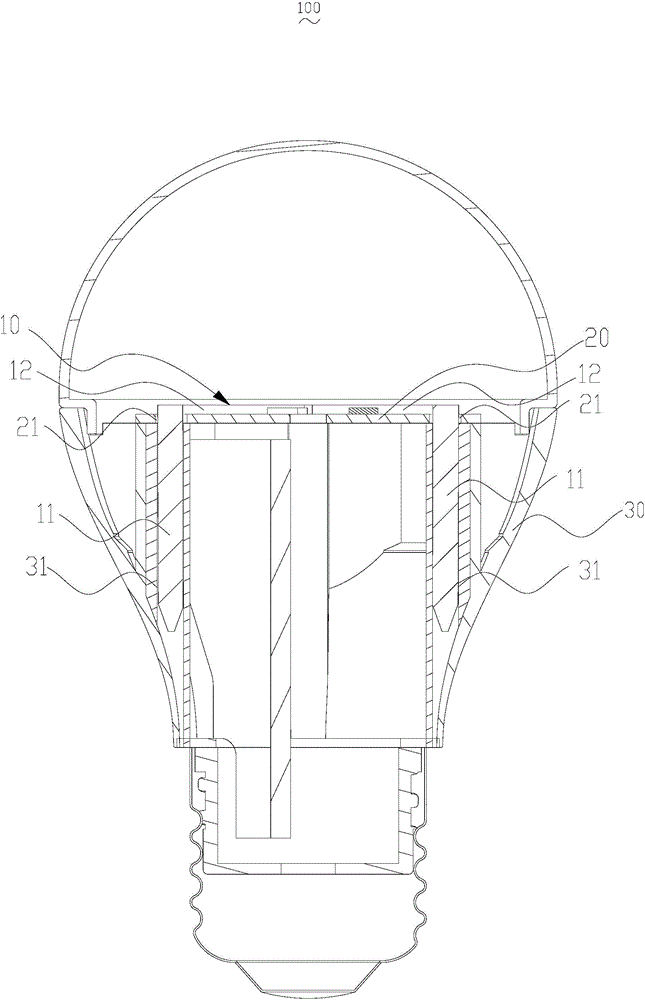

[0015] figure 1 It is an exploded view of the heat transfer rack LED lamp 100 of the present invention. The heat transfer rack LED lamp 100 includes a heat transfer rack 10 , an LED light source board 20 and a heat sink 30 . The LED light source board 20 is disposed on the top of the heat sink 30 . The heat transfer frame passes through the LED light source board 20 and is inserted into the heat sink 30 .

[0016] The heat transfer frame 10 includes at least two pins 11 and a connecting rod 12 connecting these pins. preferred, please refer to figure 1 , the heat transfer frame 10 includes four pins 11, and these connecting rods 12 are connected to each other to form a closed loop. The heat transfer frame 10 is made of metal heat conducting material.

[0017] Please refer to figure 2 , the LED light source board 20 is a thin boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com