Method for preparing deoxyribonucleic acid from waste liquid after heparin extraction of pig small intestinal mucosa

A technology of deoxyribose nucleic acid and mucosal heparin, applied in the field of preparation of deoxyribonucleic acid, can solve the problems of environmental pollution, waste of active substances in medical care, etc., and achieve the effect of simple preparation and process, rich raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In a specific embodiment, the preparation method of deoxyribonucleic acid provided by the present invention is to perform column adsorption on the waste liquid after heparin extraction of porcine small intestinal mucosa, and then perform desorption, collect the desorption liquid to adjust pH, alcohol precipitation, dehydration, and drying, specifically The process steps are as follows:

[0031] (1) Column adsorption: The ion exchange resin is loaded into the adsorption column, and the waste liquid after the heparin extraction of the porcine small intestine mucosa is extracted by the pump is adsorbed through the adsorption column;

[0032] (2) Desorption: wash the adsorption column with sodium chloride with a concentration of 0.05 to 0.2 mol / L, after draining, elute with a sodium chloride solution with a temperature of 60 to 70 °C and a concentration of 2.0 to 4.0 mol / L, Collect the desorption solution;

[0033] (3) Acid precipitation: adjust the pH of the collected des...

Embodiment 1

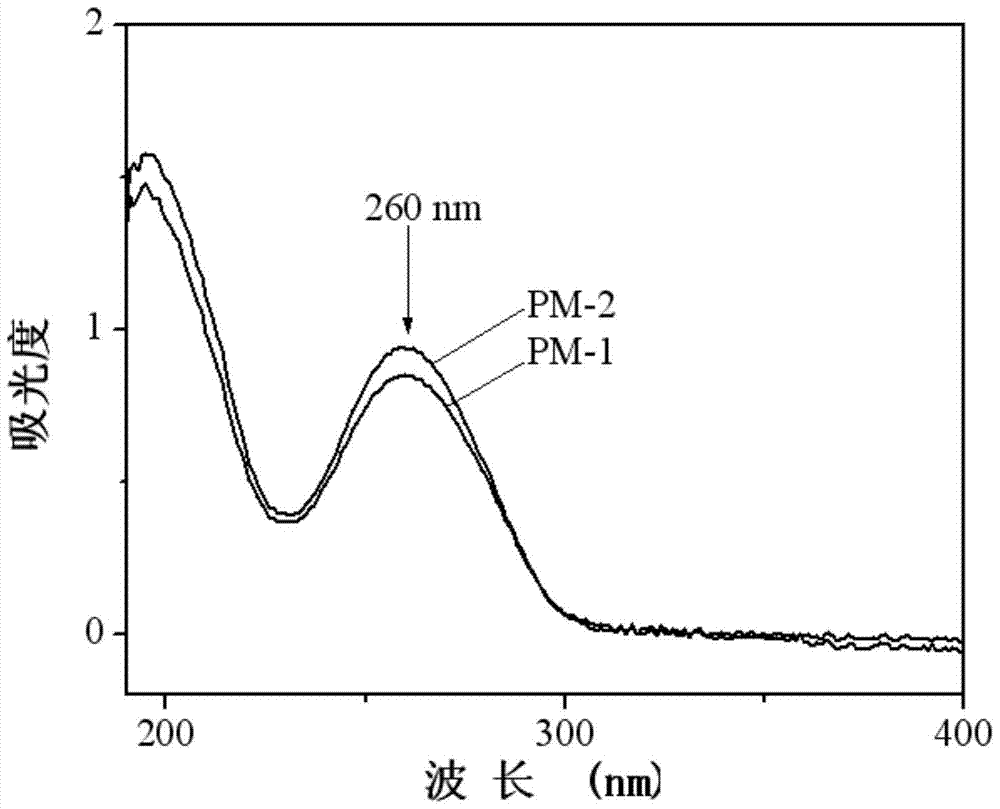

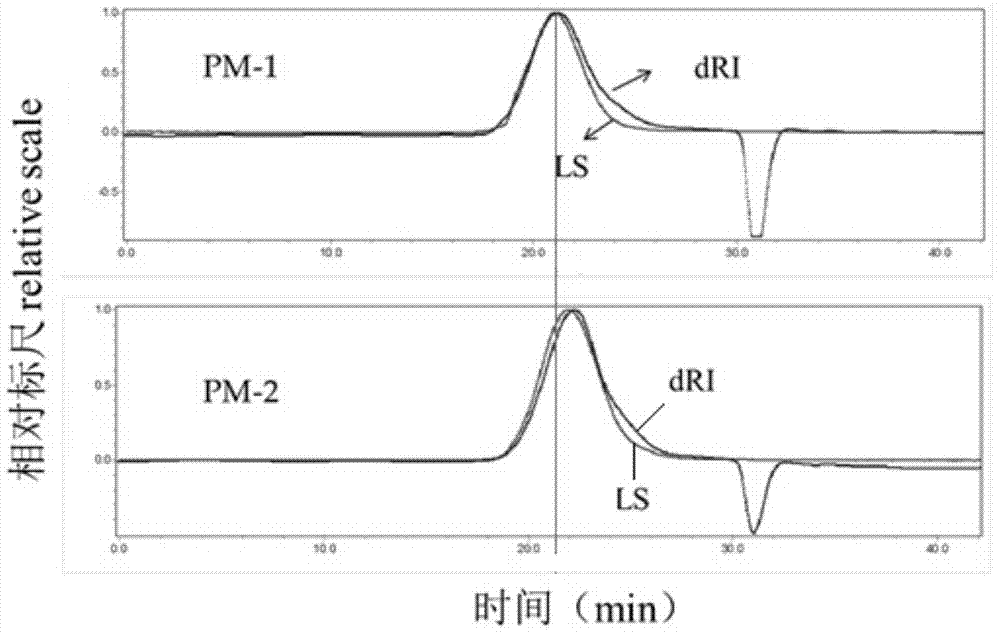

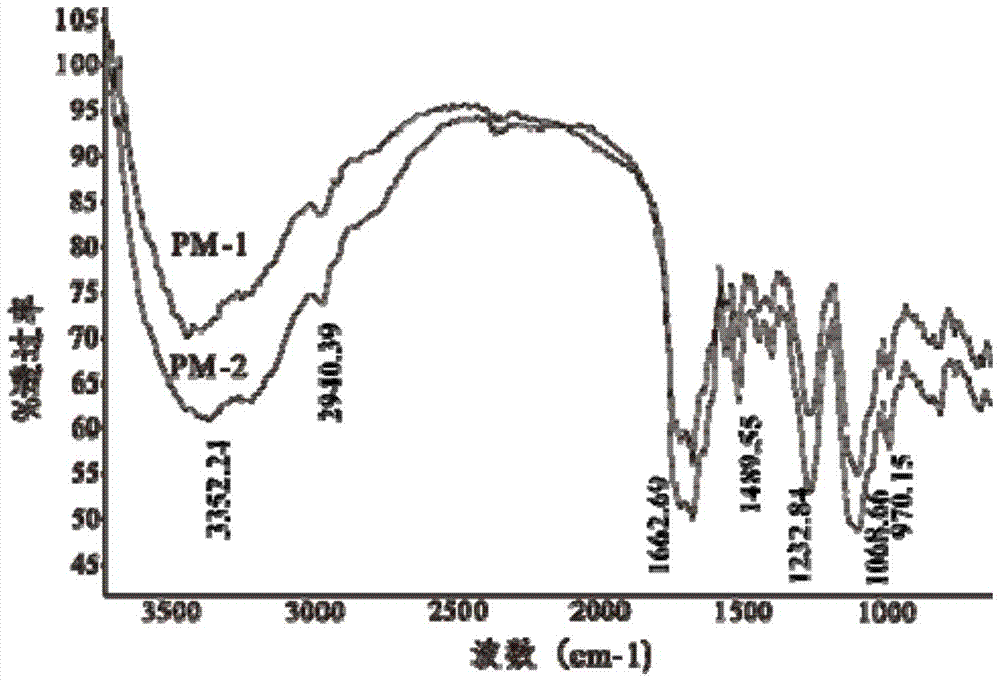

[0040] Put 200g of Rohm and Haas AMBERLITE FPA 98 CL resin into the adsorption column, and use a pump to absorb 170kg of waste liquid after heparin extraction from the porcine small intestinal mucosa through the adsorption column, and first use a sodium chloride aqueous solution with a concentration of 0.1moL / L Wash 2 times the column volume, then elute 2 times the column volume with an aqueous solution of sodium chloride at a temperature of 60°C and a concentration of 4.0 mol / L, and collect the desorption solution. Adjust the pH to 2 with 3mol / L hydrochloric acid while stirring the collected desorption solution, and let it stand at 4°C for 4h. Centrifuge, remove the supernatant, wash the precipitate three times with distilled water, remove the supernatant residue, slowly add 2mo / L sodium hydroxide aqueous solution to the precipitate until the precipitate is completely dissolved, add 3 times of ethanol with a volume fraction of 90% for precipitation , standing at 4°C for 12 ho...

Embodiment 2

[0042] Put 500g of Rohm and Haas AMBERLITE FPA 98 CL resin into the adsorption column, and use a pump to extract 570kg of waste liquid from the porcine small intestinal mucosa after heparin is absorbed through the resin. After washing the resin, elute with 2.0 mol / L aqueous sodium chloride solution at 60°C for 2 times the column volume, and collect the desorption solution. Adjust the pH to 3 with 2mol / L hydrochloric acid while stirring the collected desorption solution, and let it stand at 4°C for 6h. Centrifuge, remove the supernatant, wash the precipitate three times repeatedly with distilled water, remove the supernatant residue, slowly add 2mo / L sodium hydroxide aqueous solution to the precipitate until the precipitate is completely redissolved, add 4 times the volume fraction of 95% ethanol Precipitate, stand at 4°C for 24 hours, centrifuge to remove the supernatant, and collect the lower layer of precipitate. Dissolve the precipitate in distilled water at 50°C, stir to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com