Preparation process for silicone rubber cable sheath used for ship

A technology of cable sheath and preparation process, which is applied in the field of preparation process of silicone rubber cable sheath for ships, which can solve the problems of limited application range, poor mechanical properties such as silicone rubber tensile strength and tear strength, etc., and achieves the goal of preparing The process is simple, the mechanical performance is good, and the effect of environmental pollution is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

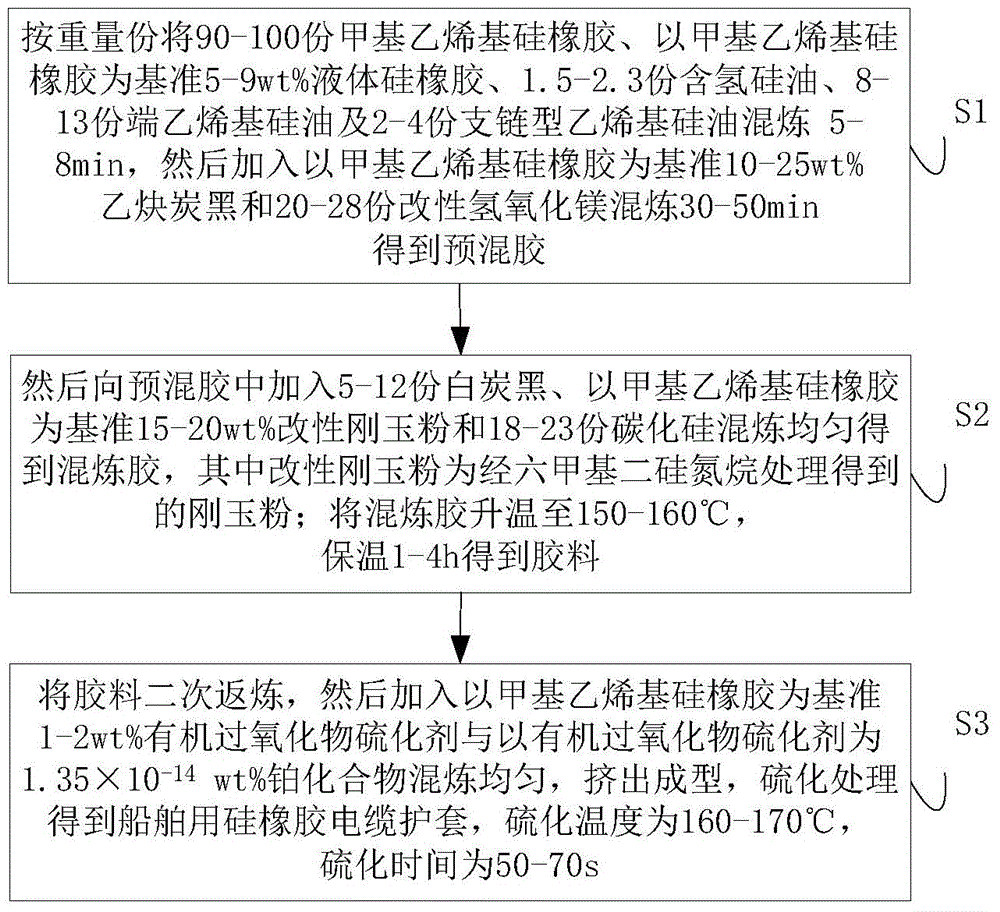

[0021] A preparation process for a ship's silicone rubber cable sheath, comprising the steps of:

[0022] S1, 90 parts by weight of methyl vinyl silicone rubber, 9 wt% liquid silicone rubber based on methyl vinyl silicone rubber, 1.5 parts of hydrogen-containing silicone oil, 13 parts of terminal vinyl silicone oil and 2 parts of branched chain vinyl The silicone oil was mixed for 8 minutes, wherein the mass fraction of hydrogen in the hydrogen-containing silicone oil was 0.0056%, and then 25 wt% acetylene carbon black based on methyl vinyl silicone rubber and 20 parts of modified magnesium hydroxide were added and mixed for 50 minutes to obtain a premixed rubber;

[0023] S2, then add 5 parts of white carbon black, 20wt% modified corundum powder based on methyl vinyl silicone rubber and 18 parts of silicon carbide to the premixed rubber and mix evenly to obtain a mixed rubber, wherein the modified corundum powder is the modified corundum powder Hexamethyldisilazane treated co...

Embodiment 2

[0026] A preparation process for a ship's silicone rubber cable sheath, comprising the steps of:

[0027] S1, 93 parts by weight of methyl vinyl silicone rubber, 5 wt% liquid silicone rubber based on methyl vinyl silicone rubber, 2.3 parts of hydrogen-containing silicone oil, 8 parts of terminal vinyl silicone oil and 4 parts of branched vinyl Silicone oil was mixed for 5 minutes, wherein the mass fraction of hydrogen in the hydrogen-containing silicone oil was 0.015%, and then 10 wt% acetylene carbon black based on methyl vinyl silicone rubber and 28 parts of modified magnesium hydroxide were added and mixed for 30 minutes to obtain a premixed rubber;

[0028] S2, then add 12 parts of white carbon black, 15wt% modified corundum powder based on methyl vinyl silicone rubber and 23 parts of silicon carbide to the premixed rubber and mix evenly to obtain a mixed rubber, wherein the modified corundum powder is the modified corundum powder Hexamethyldisilazane treated corundum powd...

Embodiment 3

[0031] A preparation process for a ship's silicone rubber cable sheath, comprising the steps of:

[0032] S1, 100 parts by weight of methyl vinyl silicone rubber, 6.8 wt% liquid silicone rubber based on methyl vinyl silicone rubber, 2.1 parts of hydrogen-containing silicone oil, 12 parts of terminal vinyl silicone oil and 3.5 parts of branched chain type ethylene Base silicone oil was mixed for 7 minutes, wherein the mass fraction of hydrogen in the hydrogen-containing silicone oil was 0.012%, and then 21 wt% acetylene carbon black based on methyl vinyl silicone rubber and 24 parts of modified magnesium hydroxide were added and mixed for 45 minutes to obtain a premixed rubber ;

[0033] S2, then add 8 parts of white carbon black, 18.5wt% modified corundum powder based on methyl vinyl silicone rubber and 21 parts of silicon carbide to the premixed rubber and mix evenly to obtain a mixed rubber, wherein the modified corundum powder is Corundum powder obtained by treating with h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com