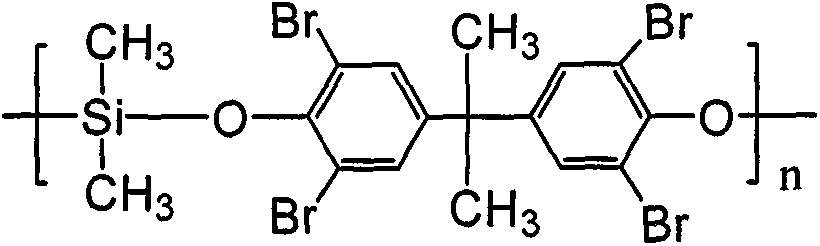

Tetrabromobisphenol-A polydimethylsilicate polymer and preparation method thereof

A technology of polydimethylsilicic acid tetrabromobisphenol and dimethylsilicic acid tetrabromobisphenol is applied in the field of polydimethylsilicic acid tetrabromobisphenol A polymer and preparation thereof, and can solve fire, People's lives and property safety threats and other issues, to prevent secondary combustion, simplify the post-processing process, and achieve the effect of low volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

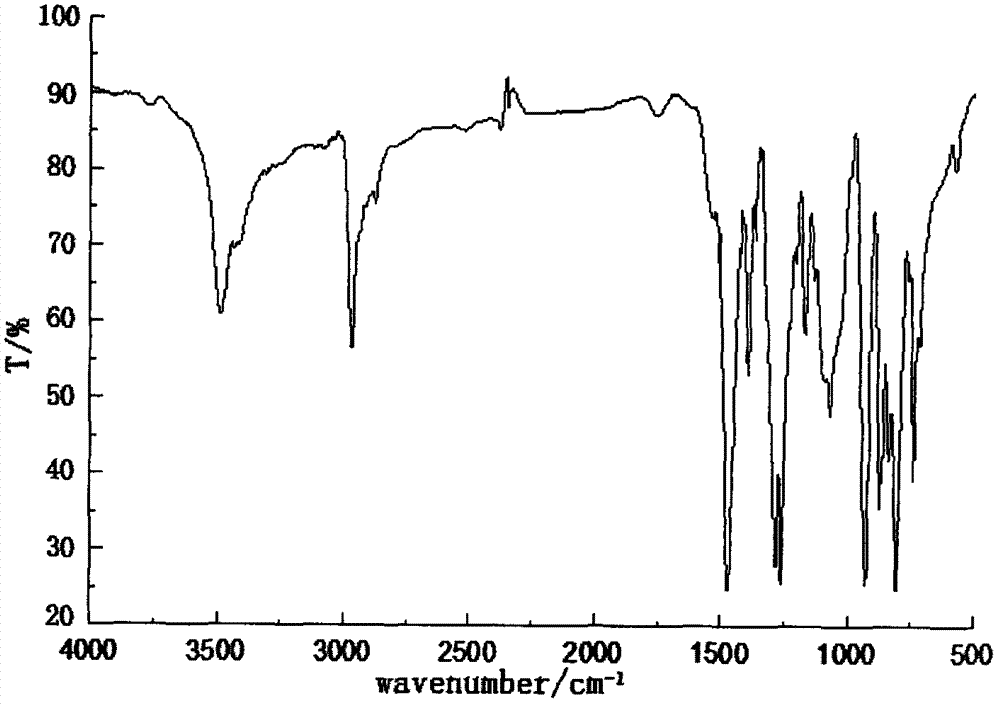

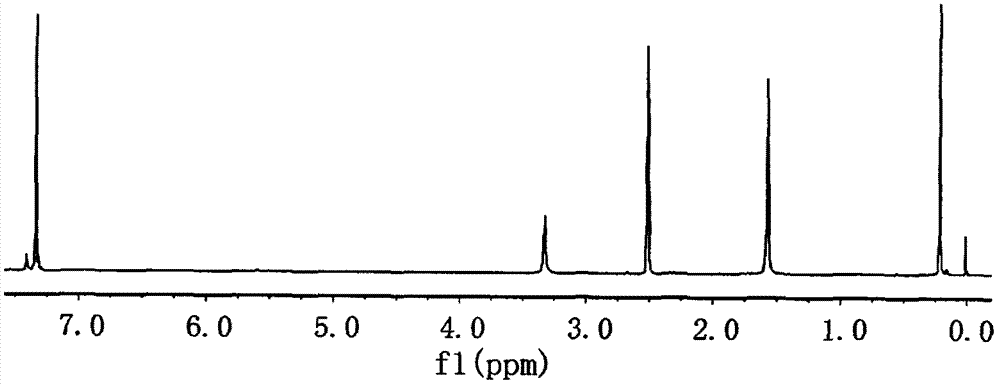

[0038] Example 1 In a 250ml four-necked bottle equipped with a stirrer, a thermometer and a condenser tube, and a drying tube on the top of the condenser tube, replace the air in the bottle with nitrogen, and add 27.19g (0.05mol) tetrabromobis Phenol A, 140ml toluene and 10.1g (0.1mol) triethylamine, add 6.45g (0.05mol) dimethyldichlorosilane dropwise, control the reaction temperature not higher than 40°C at the rate of addition, and raise the temperature to 70°C after dropping , heat preservation reaction for 8 hours, then add 0.15g of methanol dropwise as an end-capping agent, heat preservation reaction for 0.5h; lower the temperature to below 30°C, then add 30ml of distilled water to wash twice, separate the layers, and use 10g of anhydrous sodium sulfate for the obtained toluene layer. Dry, filter with suction, and distill the filtrate to remove toluene under reduced pressure to obtain tetrabromobisphenol A polydimethylsilicate, with a yield of 93.8%.

Embodiment 2

[0039]Example 2 In a 250ml four-necked bottle equipped with a stirrer, a thermometer and a condenser tube, and a drying tube on the top of the condenser tube, replace the air in the bottle with nitrogen, and add 27.19g (0.05mol) tetrabromobis Phenol A, 75ml dichloroethane and 12.63g (0.125mol) triethylamine, add dropwise 6.45g (0.05mol) dimethyldichlorosilane, control the reaction temperature with the dropping rate not higher than 40°C, and raise the temperature after dropping to 55°C, heat-retain for 10 hours, then add dropwise 0.1g of methanol as an end-capping agent, heat-retain for 0.5h; lower the temperature to below 30°C, then add 60ml of distilled water to wash twice, separate the liquid, and use the obtained dichloroethane layer with 5g of anhydrous sodium sulfate was dried, filtered with suction, and the filtrate was distilled off under reduced pressure to remove dichloroethane to obtain tetrabromobisphenol A polydimethylsilicate, with a yield of 90.8%.

Embodiment 3

[0040] Example 3 In a 250ml four-necked bottle equipped with a stirrer, a thermometer and a condenser, and a drying tube at the top of the condenser, replace the air in the bottle with nitrogen, and add 27.19g (0.05mol) tetrabromobis Phenol A, 110ml xylene and 12.63g (0.125mol) triethylamine, add dropwise 6.45g (0.05mol) dimethyl dichlorosilane, control the reaction temperature with the dropping rate not higher than 40°C, and raise the temperature to 70°C after dropping. ℃, heat preservation reaction for 7 hours, then dropwise add 0.15g of methanol as an end-capping agent, heat preservation reaction for 0.5h; lower the temperature to below 30°C, then add 30ml of distilled water to wash twice, separate the liquid, and wash the obtained xylene layer with 8g of anhydrous sulfuric acid Magnesium was dried, suction filtered, and the filtrate was distilled off under reduced pressure to remove xylene to obtain tetrabromobisphenol A polydimethylsilicate. Yield: 93.1%, weight average m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com