Special fertilizer for strawberries as well as preparation method and fertilizing method of fertilizer

A special fertilizer and strawberry technology, applied in the field of strawberry special fertilizer and its preparation, can solve the problems of unbalanced strawberry nutrition, waste of fertilizer resources, and strawberry quality degradation, and achieve the effects of improving fruit quality, promoting hypertrophy and ripening, and promoting synthesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

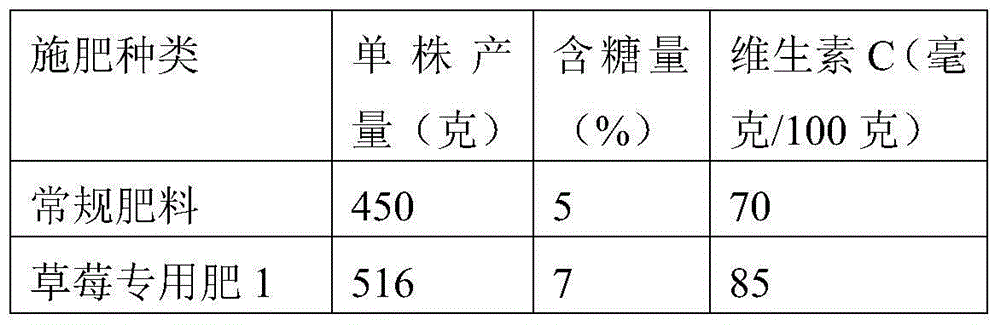

Embodiment approach 1

[0018] A: Take 25.4 parts of urea and melt it for later use;

[0019] B: Take 20.1 parts of ammonium bicarbonate, 11.4 parts of superphosphate, 20.1 parts of potassium chloride, 8.5 parts of calcium nitrate, 0.8 parts of magnesium sulfate, 0.6 parts of ethylenediamine iron acetate, 0.38 parts of zinc oxide, 0.3 parts of manganese sulfate, and sulfuric acid Put 0.15 part of copper, 0.1 part of boric acid and 0.05 part of ammonium molybdate into a mixer and stir evenly;

[0020] C: Heat the uniformly mixed raw material mixture in B to melt at 70-80 degrees Celsius;

[0021] D: Fully mix the raw material mixture melted in C and the urea melted in A into a slurry;

[0022] E: Put the slurry in D into a granulator for granulation to obtain granular strawberry special fertilizer.

[0023] The above granular strawberry special fertilizer is used as a base fertilizer. Before strawberry transplanting, the strawberry special fertilizer is sprinkled into the ground at an amount of 20 kg per mu, a...

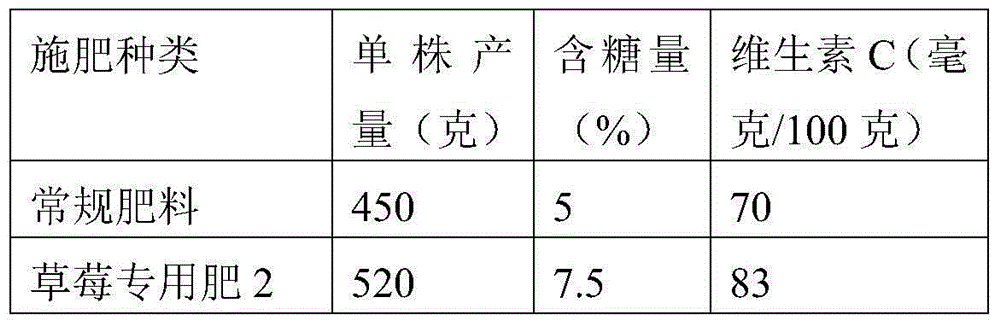

Embodiment approach 2

[0028] A: Take 27.8 parts of urea and melt it for later use;

[0029] B: Take 21.7 parts of ammonium bicarbonate, 12.5 parts of superphosphate, 22 parts of potassium chloride, 10 parts of calcium nitrate, 0.9 parts of magnesium sulfate, 0.7 parts of ethylenediamine iron acetate, 0.48 parts of zinc oxide, 0.35 parts of manganese sulfate, sulfuric acid Put 0.18 parts of copper, 0.14 parts of boric acid and 0.08 parts of ammonium molybdate into a mixer and stir evenly;

[0030] C: Heat the uniformly mixed raw material mixture in B to melt at 70-80 degrees Celsius;

[0031] D: Fully mix the raw material mixture melted in C and the urea melted in A into a slurry;

[0032] E: Put the slurry in D into a granulator for granulation to obtain granular strawberry special fertilizer.

[0033] The above granular strawberry special fertilizer is used as base fertilizer. Before strawberry transplanting, the strawberry special fertilizer is sprinkled into the ground at an amount of 25 kg per mu, and t...

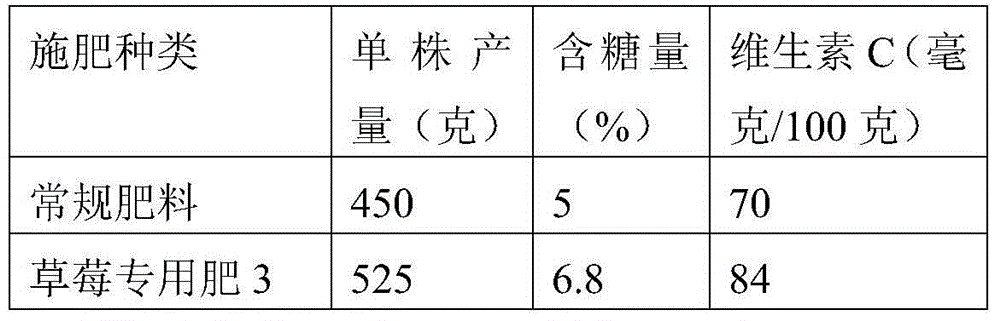

Embodiment approach 3

[0038] A: Take 30.2 parts of urea and melt it for use;

[0039] B: Take 23.3 parts of ammonium bicarbonate, 13.6 parts of superphosphate, 23.9 parts of potassium chloride, 11.4 parts of calcium nitrate, 1.0 part of magnesium sulfate, 0.8 parts of ethylenediamine iron acetate, 0.57 parts of zinc oxide, 0.4 parts of manganese sulfate, sulfuric acid Put 0.2 part of copper, 0.18 part of boric acid and 0.1 part of ammonium molybdate in a mixer and stir evenly;

[0040] C: Heat the uniformly mixed raw material mixture in B to melt at 70-80 degrees Celsius;

[0041] D: Fully mix the raw material mixture melted in C and the urea melted in A into a slurry;

[0042] E: Put the slurry in D into a granulator for granulation to obtain granular strawberry special fertilizer.

[0043] The above granular strawberry special fertilizer is used as a base fertilizer. Before strawberry transplanting, the strawberry special fertilizer is sprinkled into the ground at an amount of 30 kg per mu, and then the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com