LED UV cold light source full-gravure solvent-free printing technological method

A process method and gravure printing technology, applied in the directions of printing, post-processing of printing, printing devices, etc., can solve the problems of large heat radiation, large heat generation, high cost, etc., and achieve poor leveling and color saturation. High, finished product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] An LED UV cold light source full gravure solvent-free printing process, characterized in that: comprising the following steps:

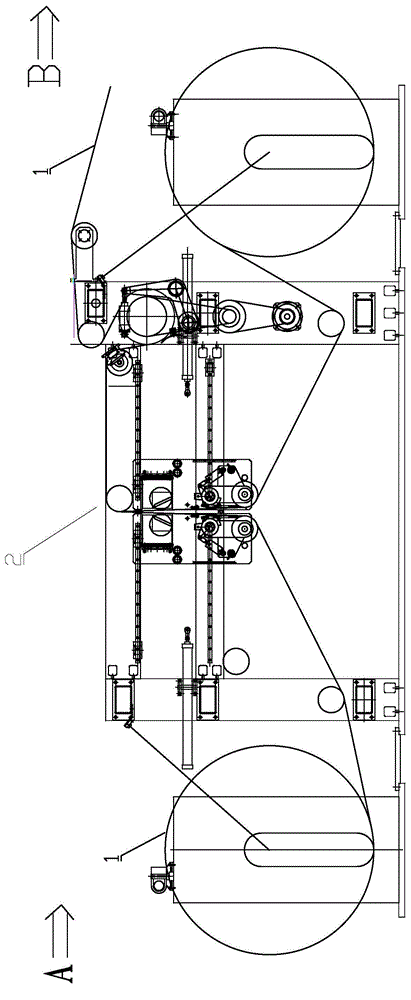

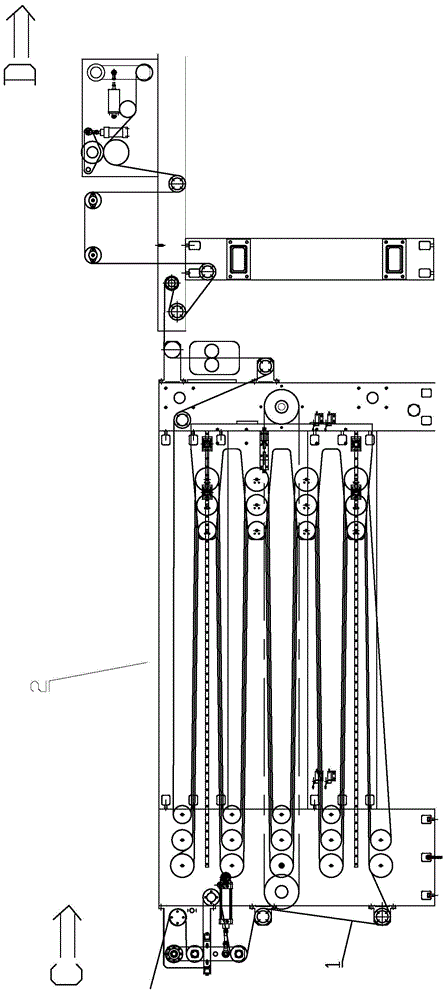

[0022] A. Load the substrate 1 onto the unwinding conveying device 2 and convey it forward;

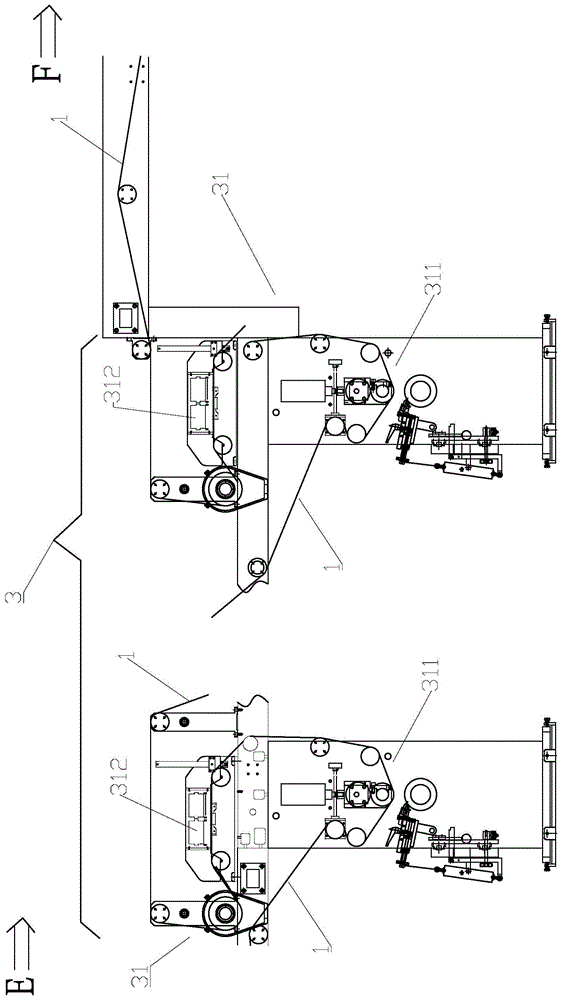

[0023] B. The unwinding conveying device 2 conveys the substrate 1 to the multi-color printing unit 3. The multi-color printing unit 3 includes a plurality of printing units 31 that are sequentially connected and each print a single color. Each of the printing units 31 It includes a UV printing machine 311 printed with UV ink and an LED UV cold light source 312 that dries the substrate 1 printed by the UV printing machine 311. The substrate 1 is sent to the gravure rubber roller and gravure printing plate of the UV printing machine 311 Between the rollers, the UV ink supply device of the UV printing machine 311 supplies ink to the gravure printing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com