Heat preservation formwork for reinforcement cage and construction method and forming die of heat preservation formwork

A technology for forming molds and construction methods, which can be used in molds, manufacturing tools, ceramic molding machines, etc., and can solve problems such as no cracks and no cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

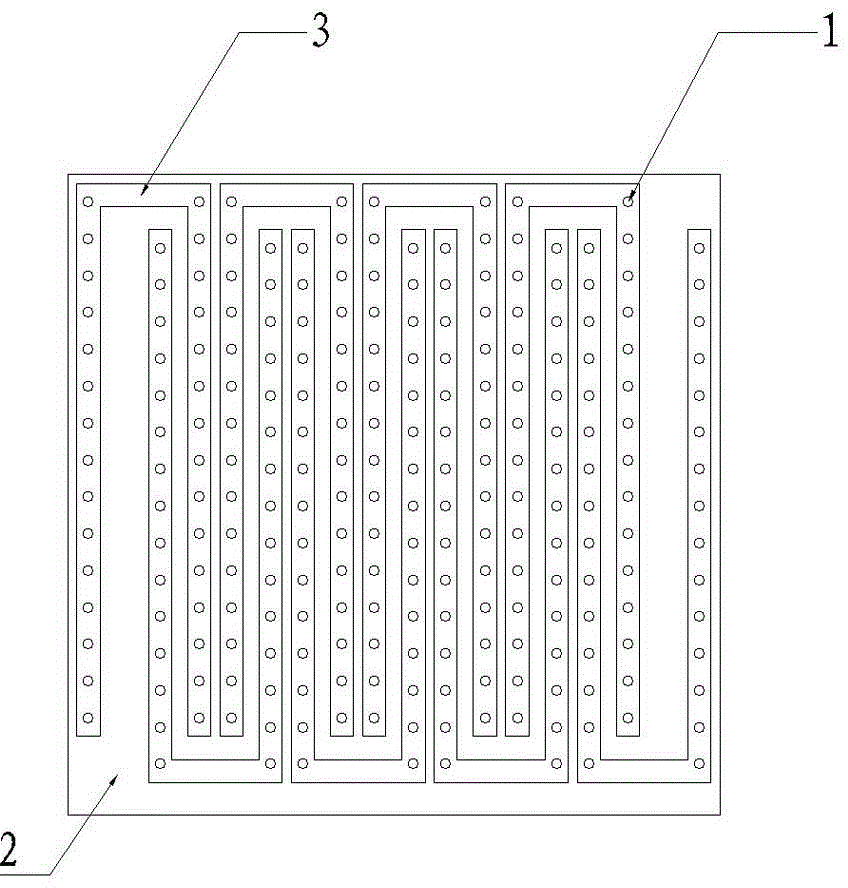

[0033] Such as figure 1 As shown, a forming mold for a heat-insulating formwork for a steel cage, a plurality of mold grooves 3 are arranged in the lower mold 2 of the forming mold, the distances between the mold grooves 3 are equal, and a number of cylindrical mold rods 1 are arranged at equal intervals in the mold , the cylindrical mold rods 1 are located on the center line of the mold and arranged at equal intervals along the length direction of the mold.

[0034] The die grooves 3 are arranged staggeredly in a U shape in the die as a whole.

[0035] The cylindrical mold rod 1 is threadedly connected with the mold cavity 3, and the bottom of the mold cavity 3 is provided with a dislocation sealing plate. The threaded holes on the bottom are in the same position.

[0036] When the dislocation sealing layer moves the threaded hole is covered, and when the dislocation sealing layer returns, the threaded hole is exposed.

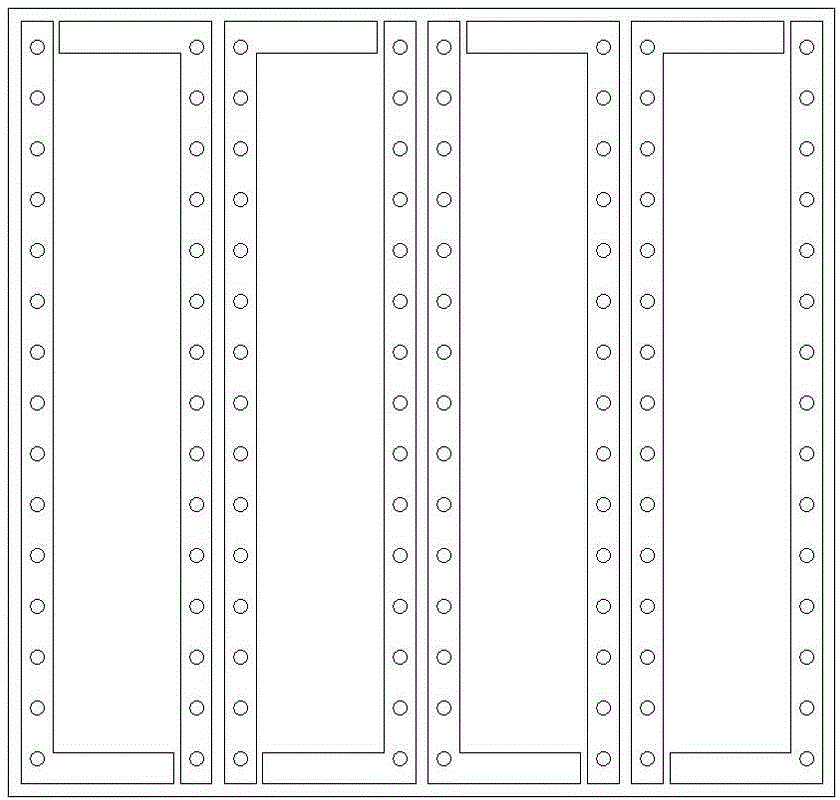

[0037] Die groove can also be as figure 2 The whol...

Embodiment 2

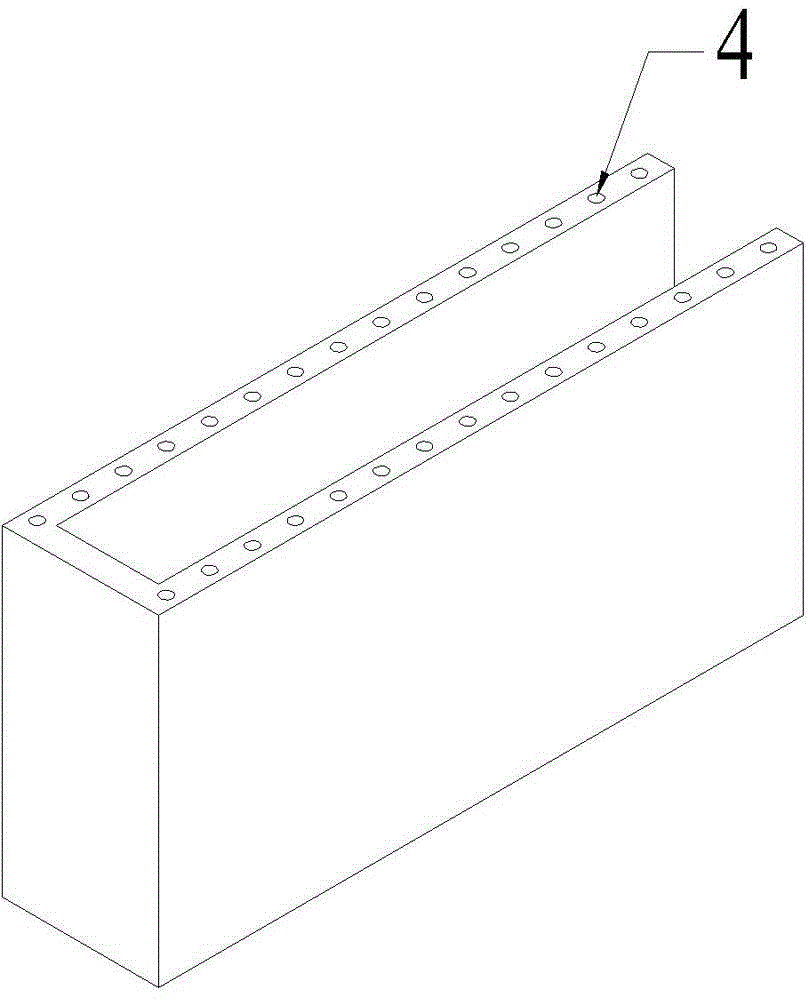

[0039] A thermal insulation formwork for a steel cage. The side wall of the thermal insulation formwork for a steel cage is provided with a cantilever (not shown in the figure), and a vertical tubular air hole 4 is opened on the side wall of the thermal insulation formwork for a steel cage.

[0040] The cantilever is a protruding claw set on the inner wall of the thermal insulation formwork for the steel cage. The rear end of the protruding claw is inserted and filled in the opening on the side wall of the thermal insulation formwork for the steel cage. The protruding claw is precast concrete Prongs.

[0041] The cantilever is a steel mesh sheet with the upper surface of the insulation formwork for the reinforcement cage. One end of the reinforcement mesh sheet is fixedly connected with the insulation formwork for the reinforcement cage, and the other end of the reinforcement mesh sheet is bent. Bending and protruding between two insulation formwork shells for steel cages, and...

Embodiment 3

[0044] A kind of construction method that utilizes the reinforcing cage in embodiment two to use thermal insulation formwork, carry out following steps:

[0045] 1) After the reinforcement cage of the wall column is firmly connected with the reinforcement cage protruding from the foundation or the floor, the reinforcement cage is glued to the side of the reinforcement cage with a thermal insulation formwork to form an insulation wall that is ringed outside the steel reinforcement. The cantilever faces of the formwork are set opposite to each other and extend into the reinforcement cage;

[0046] 2) When the masonry height of the thermal insulation formwork is greater than 25cm, conventionally set supports and railings on the outside of the thermal insulation wall formed by the thermal insulation formwork;

[0047] 3) Pump concrete into the insulation wall and pour it compactly. After the concrete hardens, remove the alignment railings and support bars.

[0048] Step 2) When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com