Three-dimensional suction cup

A suction cup, three-dimensional technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of falling suction, destroying the state of fluid rotation, and unstable adsorption, and achieve the effect of improving suction and increasing adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

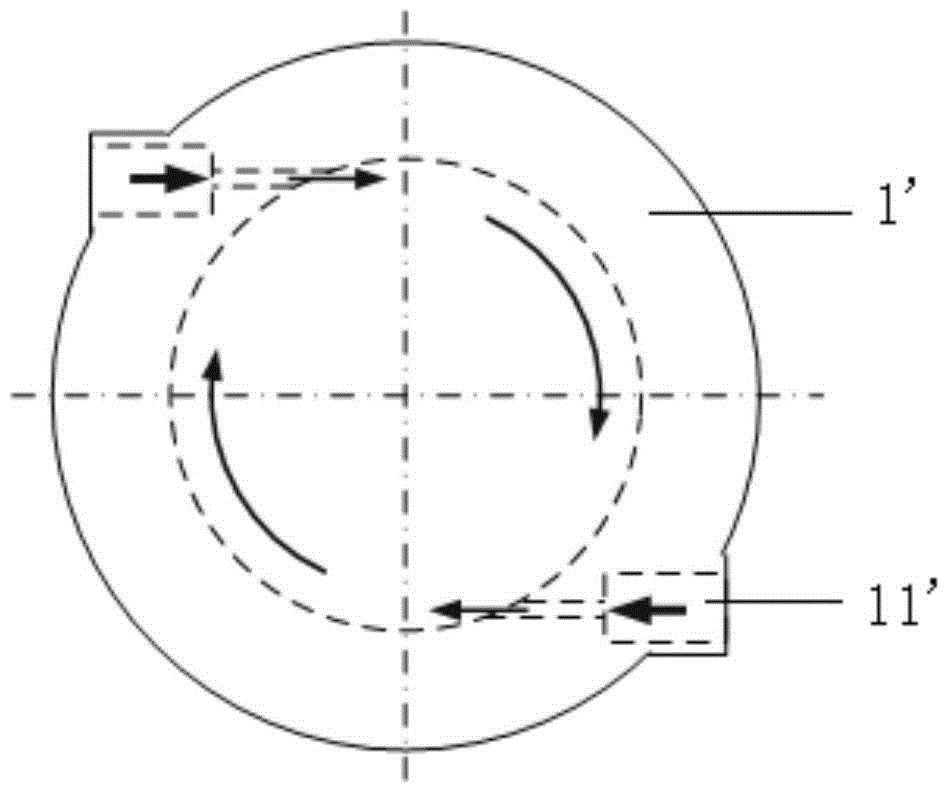

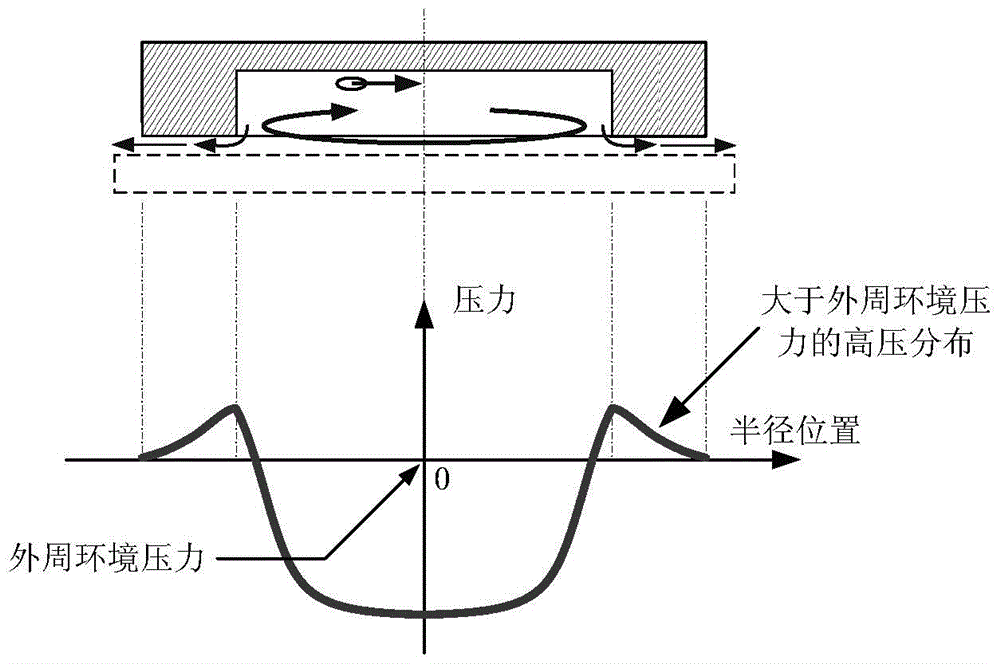

[0031] refer to Figures 4a to 4c with Figure 5b , a three-dimensional suction cup, including a suction cup body, the suction cup body has a cavity 1 with a circular cross section, the cavity has a closed end surface and an open end surface, and the wall surface of the cavity 1 is provided with compressed gas A tangential nozzle 11 connected to the source, the opening end of the cavity 1 is provided with a hollow round table 3 with a small upper part and a larger bottom, the upper opening of the hollow round table 3 coincides with the opening of the opening end face of the cavity 1 ; The inner surface of the hollow circular platform 3 is provided with a helical groove 31, the helical groove 31 forms a fixed exhaust channel, and the helical groove 31 communicates with the inner cavity and the peripheral environment.

[0032]By arranging a hollow circular platform 3 under the suction cup body, the hollow circular platform structure can expand the negative pressure action area....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com